Intelligent shell beating control system for aluminum electrolysis

A control system and technology of aluminum electrolysis, applied in the field of aluminum electrolysis, can solve the problems of hammer head loss, heat aging of seals, increase of shell surface opening, etc., to improve the recognition accuracy, avoid ablation damage, and prolong the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

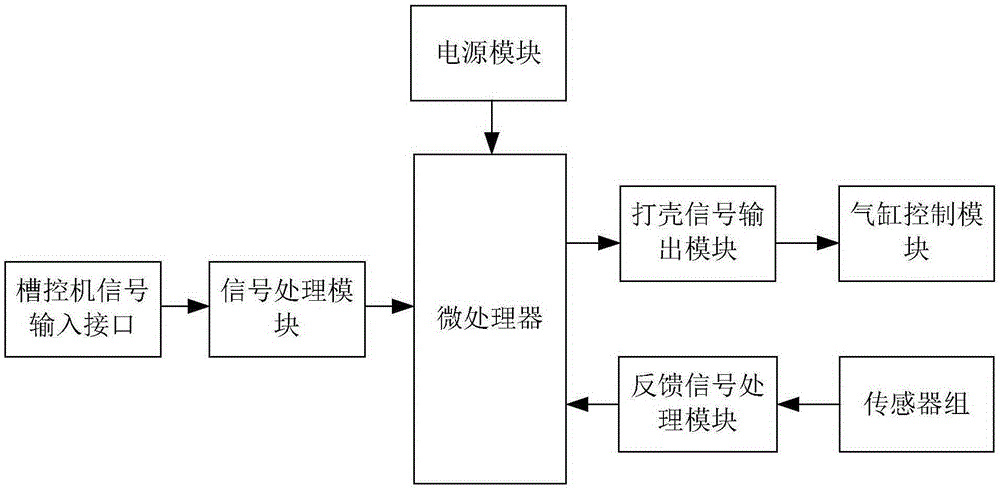

[0018] Such as figure 1 As shown, the intelligent shelling control system for aluminum electrolysis of the present invention mainly consists of a microprocessor as the control center of the system, a power module connected to the microprocessor, a signal processing module, a shelling signal output module and a feedback signal processing module, the slot control machine signal input interface connected with the signal processing module, the cylinder control module connected with the shelling signal output module, and the sensor group connected with the feedback signal processing module.

[0019] Among them, the power module is used to provide working power for the whole control system; the signal input interface of the slot control machine is connected to the external slot control machine to receive the operation signal sent by the operator; the signal processing module can process the operation signal to make the processing The latter operation signal is easier for the micropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com