Liquid silicon and preparation method thereof

A technology of liquid silicon and micro-silicon powder, applied in the field of liquid silicon and its preparation, can solve the problems of liquid inhomogeneity, easy rotten odor in storage of silicon liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

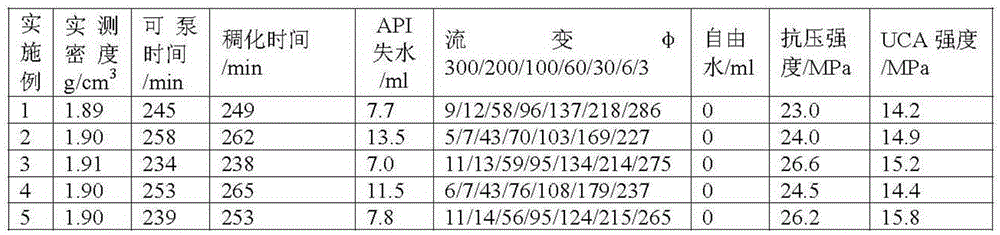

Examples

Embodiment 1

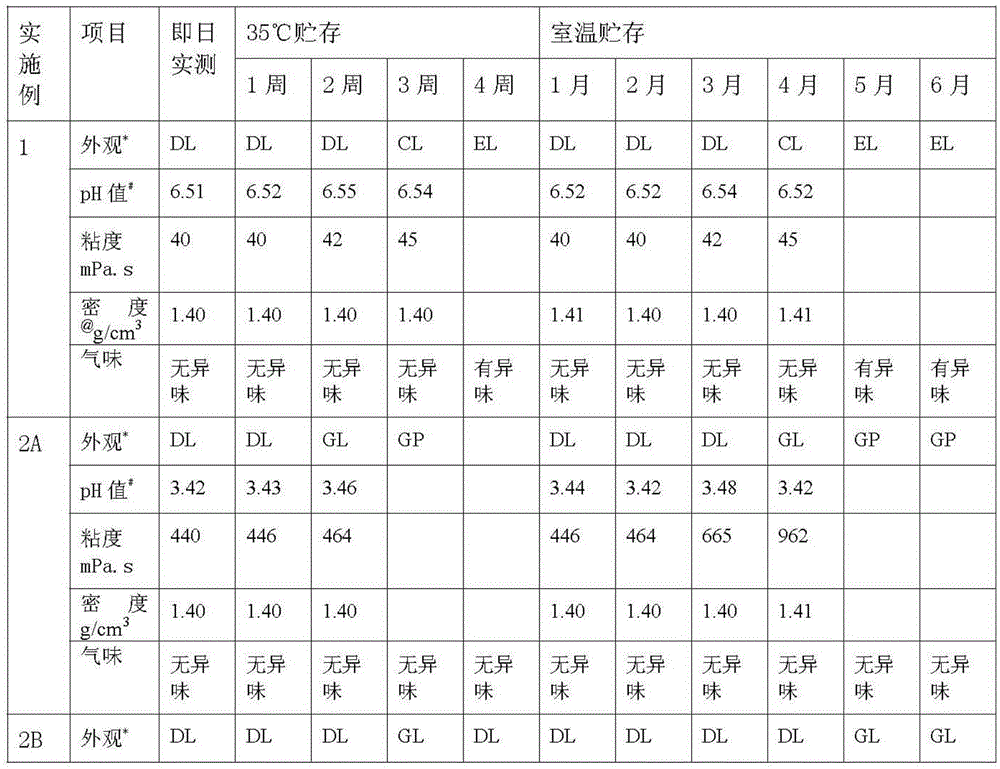

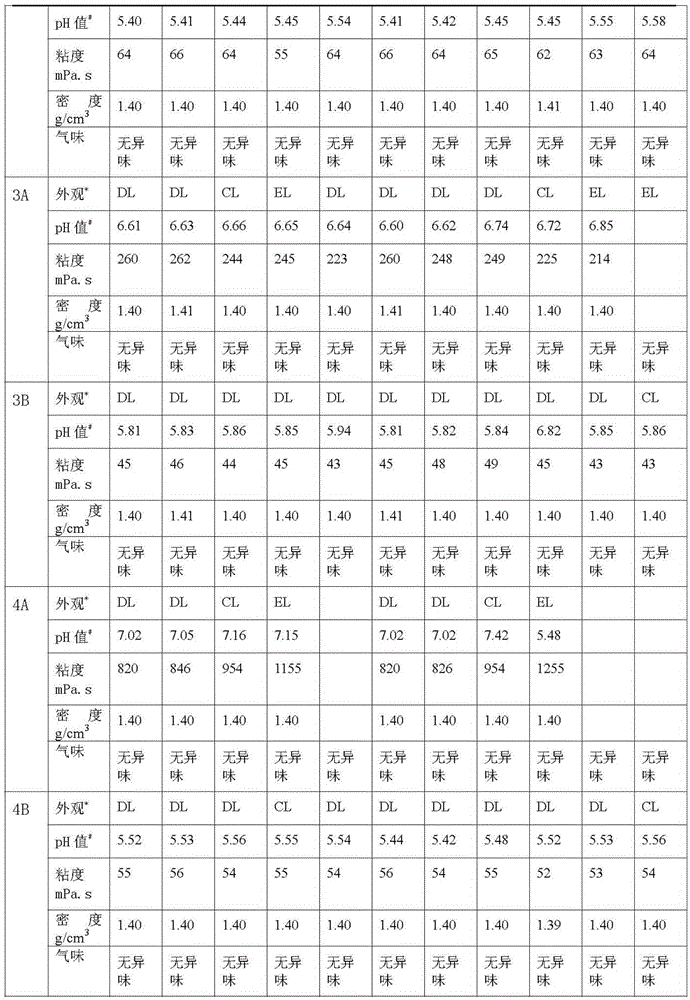

[0050] Embodiment 1 (comparative example)

[0051] 1) Put 560 grams of process water into the high-speed dispersion tank. Turn on the high-speed disperser in the dispersion tank, add 5.4 grams of FS20 dispersant and 5.4 grams of xanthan gum colloidal stabilizer at 2800-2900 rpm, and disperse at room temperature for about 5 minutes.

[0052] 2) Put 1120 grams of process water into the high-speed dispersion tank, add 1680 grams of silicon powder B1, turn on the high-speed disperser of the dispersion tank, disperse at room temperature for about 5 minutes at 2800-2900 rpm, and detect that the pH value is 7.8, add 1.2 grams of sulfuric acid ( 30%) to control the pH value to 6.4.

[0053] 3) Transfer to the adjustment tank and stir for about 1 hr at 40-100 rpm.

[0054] 4) Take a sample and measure the pH value to be 6.5, and control the viscosity at 40mPa.s.

Embodiment 2

[0056] 1) Put 1120 parts of process water into the stirring adjustment tank T-1, and put 560 parts of process water into the high-speed dispersion tank T-2. Open the dispersion tank T-2 high-speed disperser at 2900rpm.

[0057] 2) Turn on the adjustment tank T-1 to stir at 40-60rpm, and open the bottom circulation discharge valve, and at the same time turn on the submerged pump at the bottom of the dispersion tank T-2, and circulate the material back to the adjustment tank T-1 through the filter .

[0058] 3) Add 3.5kg of deodorant sodium percarbonate and 1.5kg of preservative sodium benzoate into the stirring adjustment tank T-1. After the material circulates for about 15 minutes, start to add 1680kg of silicon powder B1 to the dispersion tank T-2, check the pH value on-line to 7.8, and add 3.0kg of hydrochloric acid (10%) through a micrometering pump to control the pH value to 3.6.

[0059] 4) Keep circulating, about 1-2hrs, add silicon powder B1.

[0060] 5) On-line dete...

Embodiment 3

[0063] 1) Put 1120 parts of process water into the stirring adjustment tank T-1, and put 560 parts of process water into the high-speed dispersion tank T-2. Open the dispersion tank T-2 high-speed disperser at 1400rpm.

[0064] 2) Turn on the adjustment tank T-1 to stir at about 40rpm, and open the bottom circulation discharge valve, and at the same time turn on the submerged pump at the bottom of the dispersion tank T-2, and circulate the material back to the adjustment tank T-1 through the filter.

[0065] Add 6.5kg of deodorant sodium percarbonate and 3.0kg of preservative sodium benzoate to the stirring adjustment tank T-1. After the material circulates for about 15 minutes, start to add 1680kg of silicon powder A1 to the dispersion tank T-2, and check the pH value online to be 3.5.

[0066] 3) Add 28.5.0 kg of sodium hydroxide (10%) through a micro metering pump to control the pH value to 6.8.

[0067] 4) Keep circulating, about 1-2hrs, add silicon powder A1.

[0068] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com