Polymer composite material with double-network structure and preparation method thereof

A technology of network structure and composite materials, which is applied in the field of network structure polymer composite materials and its preparation, can solve problems such as limited effects, achieve low cost, facilitate popularization and application, and improve thermal and electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

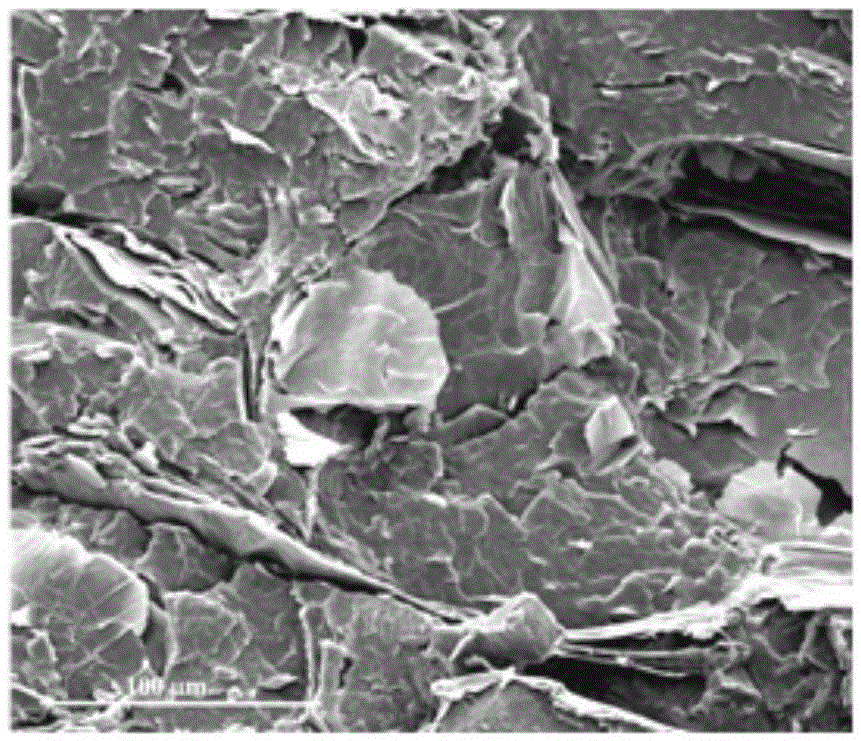

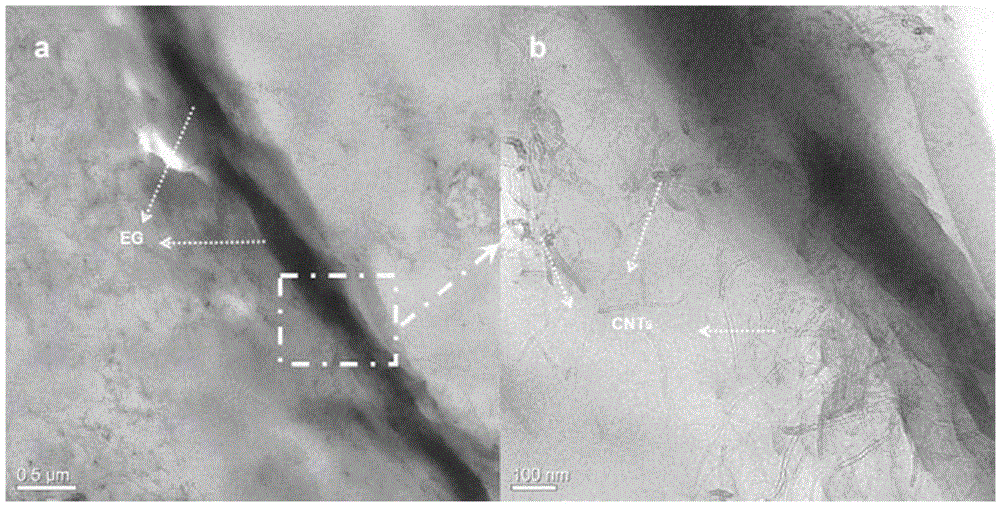

[0034] 100 parts of polypropylene (PP) powder, 15 parts of low-temperature expanded graphite (EG) with a flake size of 30-150 μm and 3 parts of multi-walled carbon nanotubes (CNTs) with an average length of 1.5 μm and an outer diameter of 9.5 nm After fully premixed, add it to an internal mixer, and mix for 10 minutes at 190°C and 60 rpm to obtain a polypropylene composite material with a double network structure. After the composite material was molded at 190°C, not only the electrical conductivity and thermal conductivity were tested, the results are shown in Table 1, but also the frozen section was observed with a scanning electron microscope, see figure 2 d, e, f, and TEM observation, see image 3 .

Embodiment 2

[0036] 100 parts of polypropylene (PP) powder, 15 parts of low-temperature expanded graphite (EG) with a flake size of 30-150 μm, and 5 parts of multi-walled carbon nanotubes (CNTs) with an average length of 1.5 μm and an outer diameter of 9.5 nm After fully premixed, add it to an internal mixer, and mix for 10 minutes at 190°C and 60 rpm to obtain a polypropylene composite material with a double network structure. The composite material was molded at 190°C, and the electrical conductivity and thermal conductivity were tested. The results are shown in Table 1.

Embodiment 3

[0038] 100 parts of thermoplastic elastomer polyurethane (TPU) powder, 25 parts of low-temperature expanded graphite (EG) with a flake size of 150-300 μm, and 5 parts of multi-walled carbon nanotubes with an average length of 1.5 μm and an outer diameter of 9.5 nm ( CNTs) were fully premixed and added to the internal mixer, and mixed for 10 minutes under the conditions of 180 ° C and 60 rpm to obtain a polyurethane composite material with a double network structure. The composite material was molded at 180°C, and the electrical conductivity and thermal conductivity performance tests were performed. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com