Polypropylene composite material capable of resisting gamma ray irradiation and preparation method of polypropylene composite material

A composite material, polypropylene technology, applied in the field of polypropylene materials, to achieve the effects of reducing degradation reactions, improving impact resistance, and excellent transparency

Active Publication Date: 2016-01-20

SICHUAN JINHE RADIATION TECH CO LTD

View PDF6 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although hindered amine light stabilizers and hindered phenol stabilizers can prevent PP from degrading after irradiation, due to the introduction of hindered phenol stabilizers, it is easy to form quinones and cause color after irradiation.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

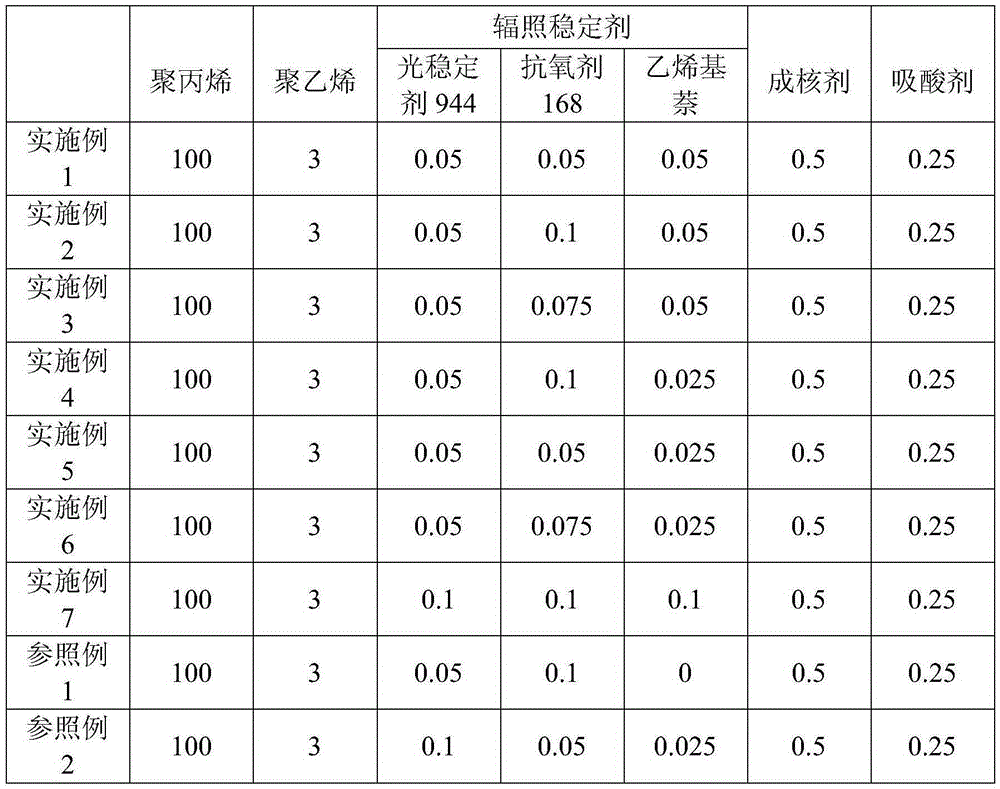

[0046] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a polypropylene composite material capable of resisting gamma ray irradiation and a preparation method of the polypropylene composite material. The polypropylene composite material comprises polypropylene resin and an irradiation stabilizer, wherein the irradiation stabilizer comprises poly{[6-[(1,1,3,3-tetramethylbutyl) amino]]-1,3,5-triazine-2,4-[(2,2,6,6-tetramethyl-piperidyl) imino]-1,6-hexamethylenediamine[(2,2,6,6-tetramethyl-4-piperidyl) imino]}, tri[2,4-di-tert-butyl phenyl] phosphite ester and vinylnaphthalene. By the optimization of the formula of the irradiation stabilizer, the irradiation resistance of polypropylene is improved; the prepared polypropylene material is high in after-irradiation transparency; the mechanical property of the polypropylene material is basically not reduced; meanwhile, the yellowness index is smaller than 3.

Description

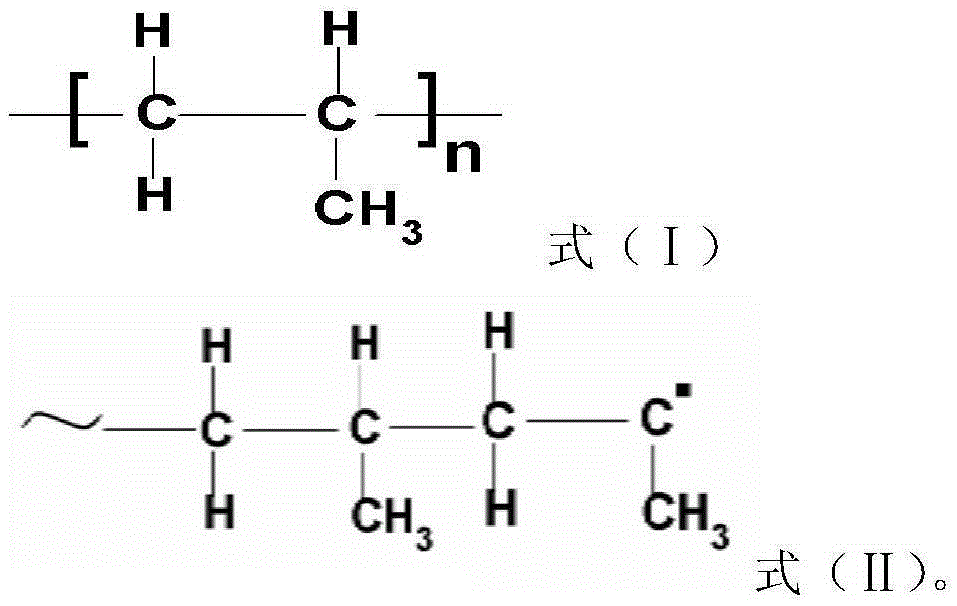

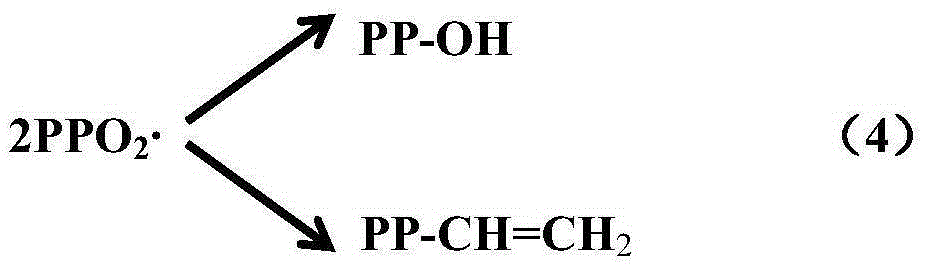

technical field [0001] The invention belongs to the field of polypropylene materials, and in particular relates to a gamma-ray radiation-resistant polypropylene composite material and a preparation method thereof. Background technique [0002] So far, there are three main disinfection methods for medical supplies in the world: conventional heating (cooking, steam) disinfection, ethylene oxide disinfection and irradiation disinfection. Heat disinfection consumes a lot of energy and the disinfection is not complete. Ethylene oxide is not only acutely toxic, but also mutagenic and carcinogenic. Compared with the first two methods, the radiation disinfection method has the advantages of complete disinfection and no residue, and is the most promising disinfection method in the world today. [0003] Polypropylene is widely used in the field of medical devices due to its excellent comprehensive properties. However, the radiation stability of ordinary medical PP is poor. After ra...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F255/02C08K5/526C08L23/12C08L23/06C08L65/00

Inventor 梁翊朱智超彭雄厚李林鹏

Owner SICHUAN JINHE RADIATION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com