Electrochromic laminated glass and preparation method thereof

A laminated glass, electrochromic technology, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the inconvenience of electrochromic laminated glass packaging and the difficulty of making large-area electrochromic Laminated glass and other issues, to ensure efficient selectivity, automatic color control, and reduce energy load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

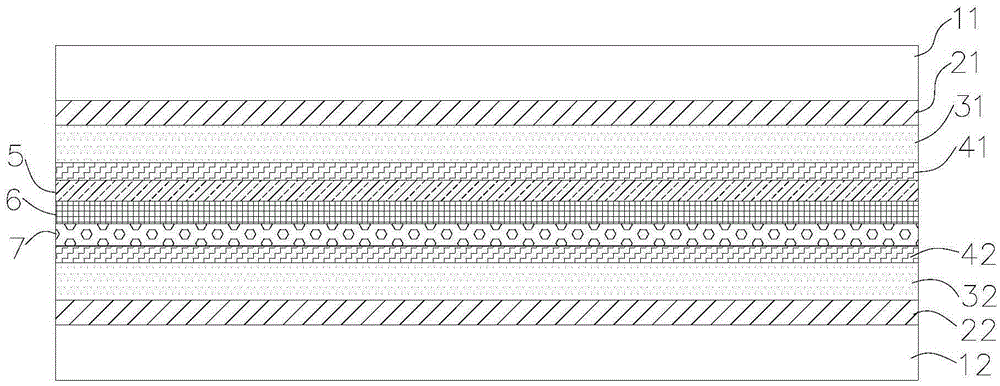

[0034] This embodiment provides an electrochromic laminated glass, such as figure 1 Shown, and the preparation method of this kind of laminated glass.

[0035] When preparing electrochromic laminated glass, a solid gel electrolyte is prepared first, and in the electrochromic laminated glass, the solid gel electrolyte is used as an ion transport layer. The specific preparation method is as follows:

[0036] (1) Preparation of solid gel electrolyte

[0037] Weigh in turn 16gKH-570 (coupling agent), 16gTBEC (crosslinking agent, Lanzhou Auxiliary Factory), 8gOP-356 (ultraviolet absorber, Yongguang Chemical) and 20gPEG (polyethylene glycol) and 2g lithium perchlorate, Mix all materials evenly to obtain conductive paste. Accurately weigh 2000g EVA resin (Mitsui Japan, VA:33, MI:30g / 10min) and place it in a mixer, then add the conductive paste to the mixer equipped with EVA resin and stir evenly, and mix the EVA The system was flattened into a flat vulcanizer to form a film, the ...

Embodiment 2

[0046] This embodiment provides an electrochromic laminated glass and a preparation method of the laminated glass. The specific preparation method is as follows:

[0047] (1) Preparation of solid gel electrolyte

[0048] Weigh in turn 16gKH-570 (coupling agent), 16gTBEC (crosslinking agent, Lanzhou Auxiliary Factory), 8gOP-356 (ultraviolet absorber, Yongguang Chemical), 20g ethylene glycol and 4g lithium perchlorate, and mix the materials Evenly, a conductive paste is obtained. Accurately weigh 2000g EVA resin (Mitsui Japan, VA:33, MI:30g / 10min) and place it in a mixer, then add the conductive paste to the mixer equipped with EVA resin and stir evenly, and mix the EVA Add the system to a single-screw extruder, control the temperature of the screw to 80°C, the temperature of the die to 90°C, and the thickness of the film to be 0.38mm, and cast it into a film. The formed solid gel electrolyte film can be used as an ion transport layer. spare.

[0049] (2) Preparation of the ...

Embodiment 3

[0056] This embodiment provides an electrochromic laminated glass and a preparation method of the laminated glass. The specific preparation method is as follows:

[0057] (1) Preparation of solid gel electrolyte

[0058] Weigh in turn 16gKH-560 (coupling agent), 16gCQ-335 (crosslinking agent, Lanzhou Auxiliary Factory), 8gOP-356 (ultraviolet absorber, Yongguang Chemical), 20gPC (anhydrous propylene carbonate) and 8g potassium perchlorate , Mix all the substances evenly to obtain the conductive paste. Accurately weigh 2000g EVA resin (Mitsui Japan, VA:33, MI:30g / 10min) and place it in a mixer, then add the conductive paste to the mixer equipped with EVA resin and stir evenly, and mix the EVA Add the system to a single-screw extruder, control the temperature of the screw to 80°C, the temperature of the die to 90°C, and the thickness of the film to be 0.38mm, and cast it into a film. The formed solid gel electrolyte film can be used as an ion transport layer. spare.

[0059] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com