Movable sucker device for die

A technology of suction cups and molds, applied in the direction of coating, etc., can solve the problems of poor reliability of manipulators and positioning parts, inability to place hardware in place, and shorten the service life of molds, so as to reduce the depth of space intersection and reduce the pressure of film pressing Risk, Effect of Avoiding Injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is further described in conjunction with the following examples.

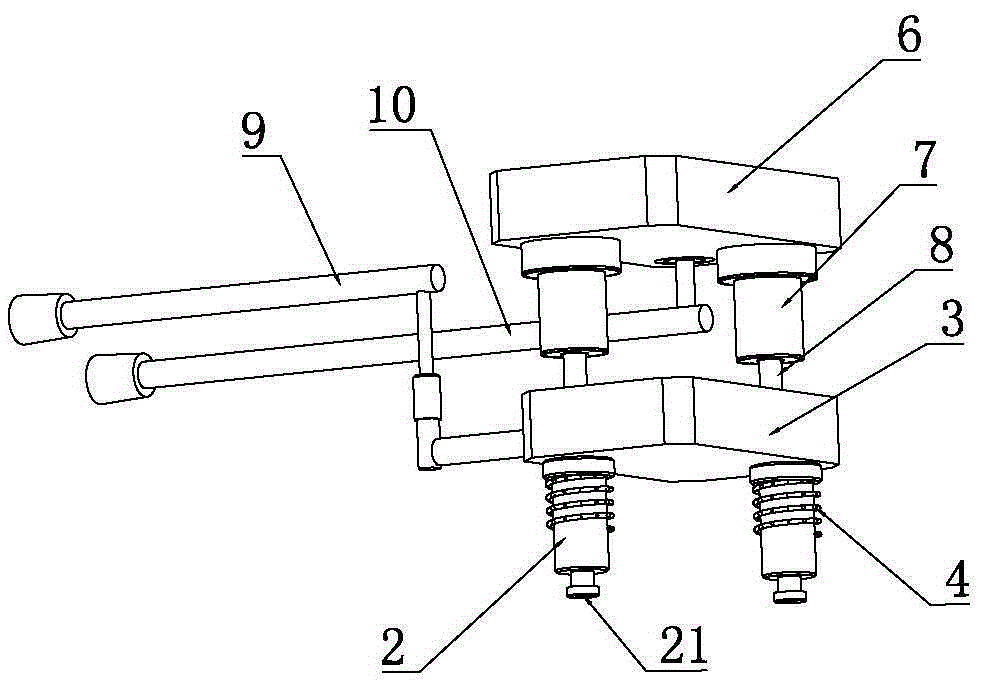

[0035] A specific embodiment of a movable suction cup device for a mold of the present invention, as figure 1 with figure 2 As shown, it includes suction cup 2, positioning pin 5 and ejection assembly. The suction cup 2 and positioning pin 5 are set on the mold 1. The suction cup 2 can slide up and down relative to the mold 1. The ejection assembly (6, 7, 8) can push the suction cup 2 downward movement, and then push the suction end 21 of the suction cup 2 out of the molding surface of the mold 1 .

[0036] Such as figure 2 with image 3 As shown, the mold 1 is also provided with a suction plate 3 that can slide up and down relative to the mold 1, the suction cup 2 is fixed on the bottom of the suction plate 3, and the suction pipe 31 in the suction plate 3 communicates with the suction pipe 22 of the suction cup 2 and the first air supply source pipe 9 , the ejection assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com