Automobile plate spring shot blasting apparatus and shot-blasting process

A technology for automotive plates and equipment, applied in metal processing equipment, manufacturing tools, used abrasive processing devices, etc., can solve the problem of affecting the speed and quality of the continuous cycle of shot blasting, the inability to achieve workpiece surface polishing, and the inability to realize automatic Sorting and filtering out problems to achieve the effect of improving shot blasting quality and efficiency, improving surface quality, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

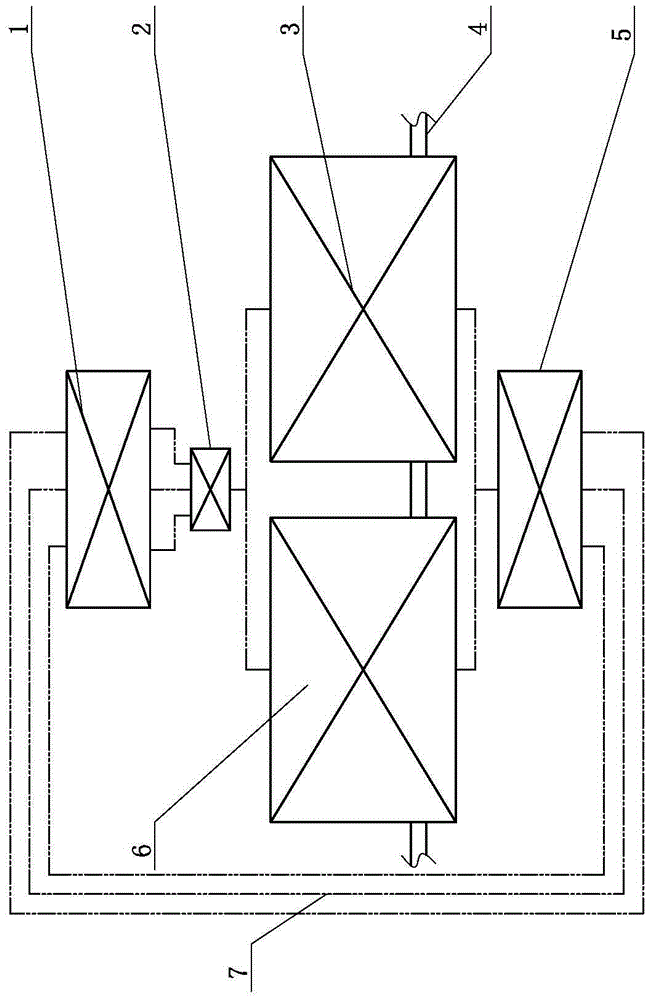

[0046] Such as figure 1 As shown, a kind of automobile leaf spring shot blasting equipment according to the present invention includes a shot blasting device, a weighing shot delivery device, a shot blasting device and a steel shot recovery device, and the output port of the shot storage device is connected in sequence through a delivery pipe to weigh Heavy shot device, shot blasting device and steel shot recovery device, the steel shot recovery device is connected to the input port of the shot storage device through a ladder conveyor belt.

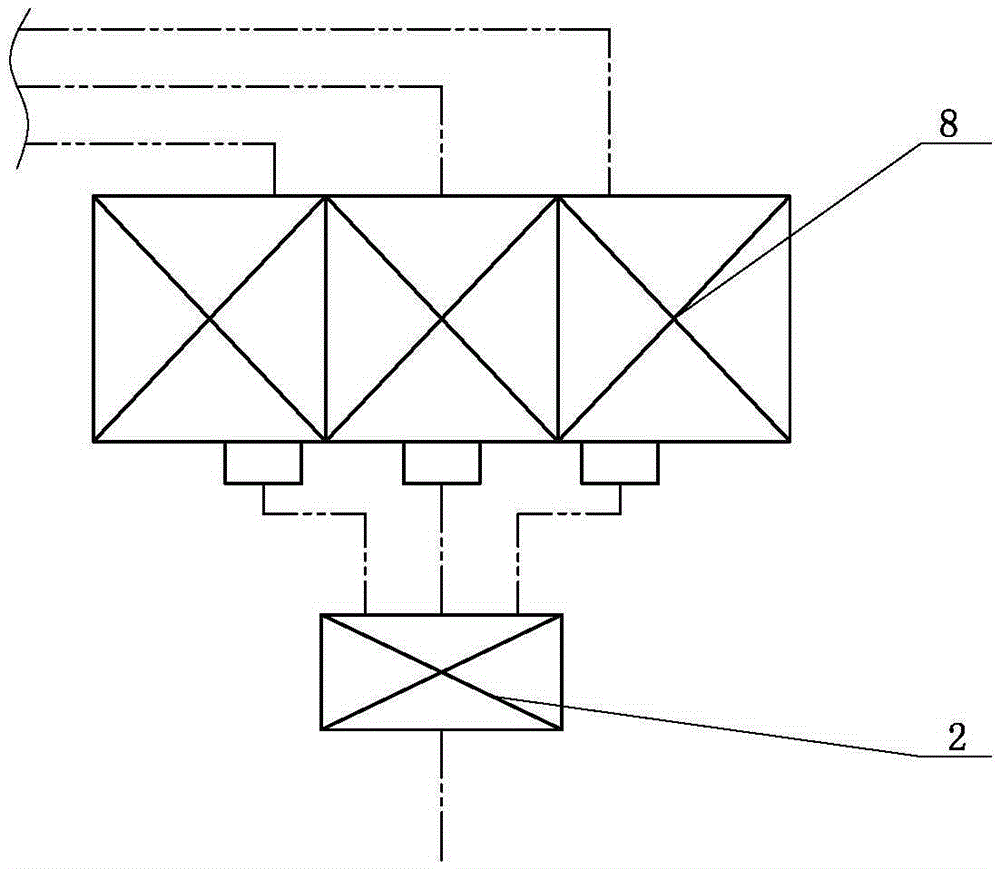

[0047] Such as figure 2 As shown, the described shot storage device includes several shot storage chambers, and steel shots with different diameters are placed in each shot storage chamber; an input port and an output port are respectively set up on each shot storage room, and each output port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com