Anti-blocking soybean pulping device

A soybean and pulp refining technology, applied in milk substitutes, cocoa, grain processing and other directions, can solve the problems of large equipment footprint, overloaded operation of the refiner, and high production costs, achieving a small footprint and avoiding poor feeding. Average and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

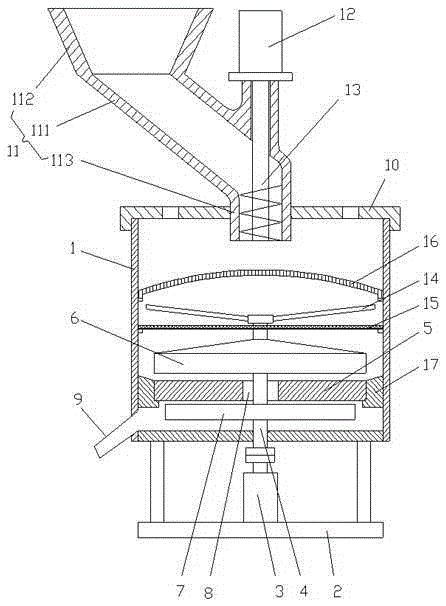

[0013] As shown in the figure, the anti-blocking type soybean refining device of this embodiment includes a cylindrical casing 1, a support 2 supporting the casing, a motor 3 arranged on the support, and a motor rotor connected to the motor and vertically upward. Deep into the rotating shaft 4 in the casing, the casing is provided with a fixed grinding disc 5 fixed horizontally, and the rotating shaft is provided with a coarse grinding movable grinding disc 6 matched with the upper end surface of the fixed grinding disc and a fine grinding disc 6 matched with the lower end surface of the fixed grinding disc. Grinding grinding disc 7; the middle part of the fixed grinding disc is provided with a blanking hole 8, and the upper end surface of the rough grinding fixed grinding disc is a conical surface; the casing is also provided with a slurry outlet pipe 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com