A Simultaneous Desulfurization and Denitrification Process Based on Electrolytic Regeneration for Iron Removal in Flue Gas and Ammonia

An electrolytic regeneration, desulfurization and denitrification technology, applied in the field of flue gas desulfurization and denitrification technology, can solve the problems of large consumption of iron scraps, easy corrosion of iron scraps, affecting conversion efficiency, etc., and achieves low investment cost and operating cost, and desulfurization and denitrification effect. Good, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

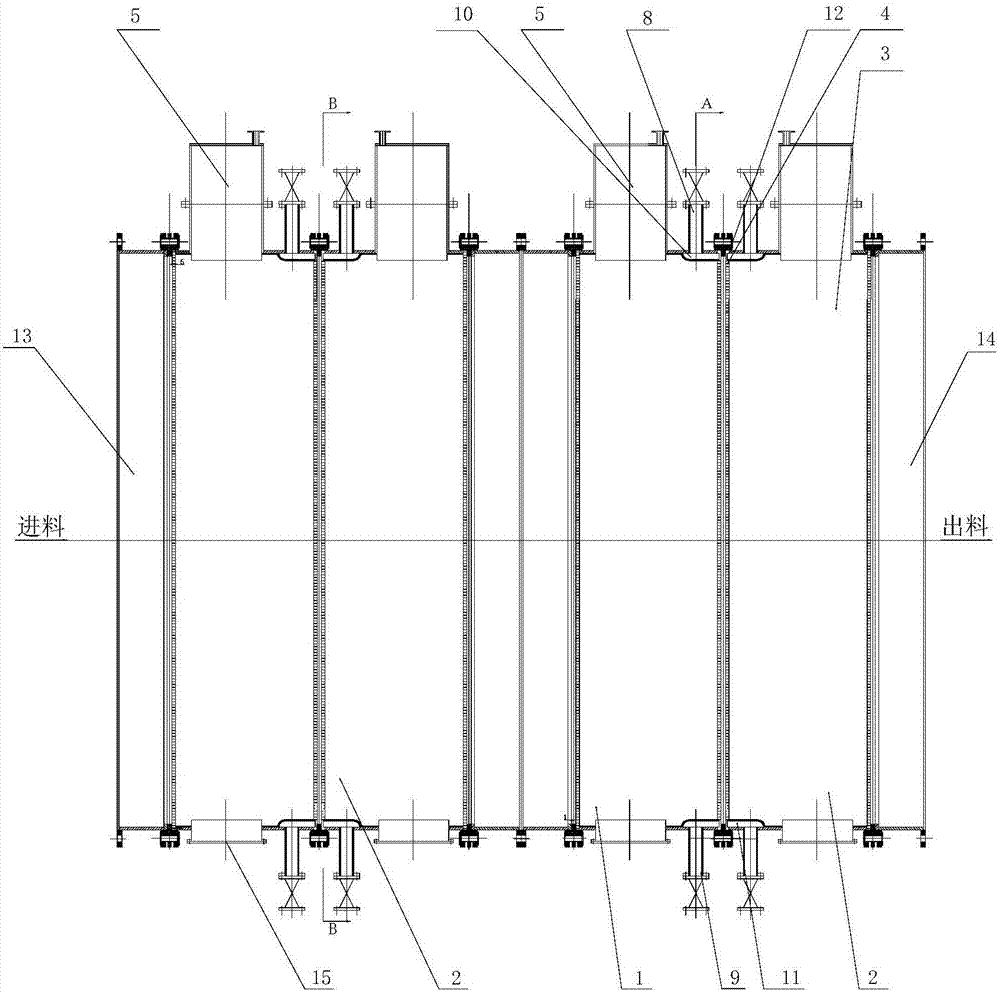

[0054] Below in conjunction with accompanying drawing, the present invention will be further explained:

[0055] Denitration process:

[0056] see Image 6 , after the flue gas is pressurized, it is sent into the concentration tower 16 to contact and react with the concentrated liquid in the tower. The concentrated liquid is sent to the ammonium sulfate crystallization system 21 to obtain ammonium sulfate crystals after being deironed by the first electrolytic reactor 18, and the absorbed liquid after the partial reaction at the bottom of the absorption tower 17 is regenerated by the second electrolytic reactor 19 and then sent to the regeneration slurry tank 20 , the absorption liquid in the regenerated slurry tank is sent back to the absorption tower 17 as a circulating absorption liquid.

[0057] The structure of the first electrolysis reactor 18 and the second electrolysis reactor 19 can be a vertical or horizontal reactor with a reaction unit,

[0058] Among them, see ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com