Special tank for discharging whey from cheese

A whey discharge and special tank technology, applied in the direction of cheese substitutes, applications, dairy products, etc., can solve the problems of increasing filtration separation, low work efficiency, and long time for whey shooting, so as to improve work efficiency and speed , ingeniously designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

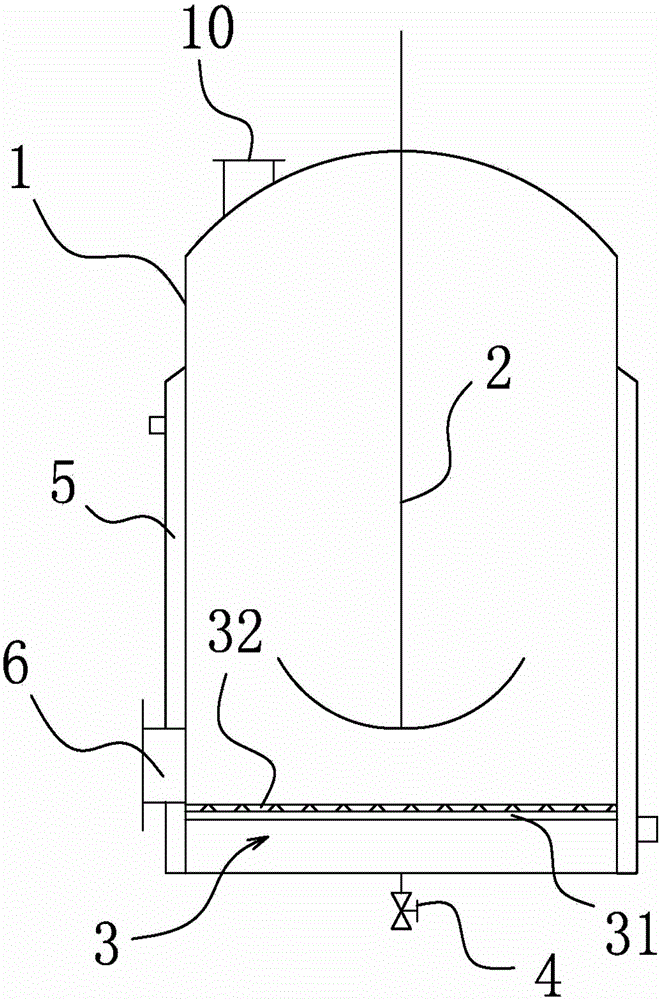

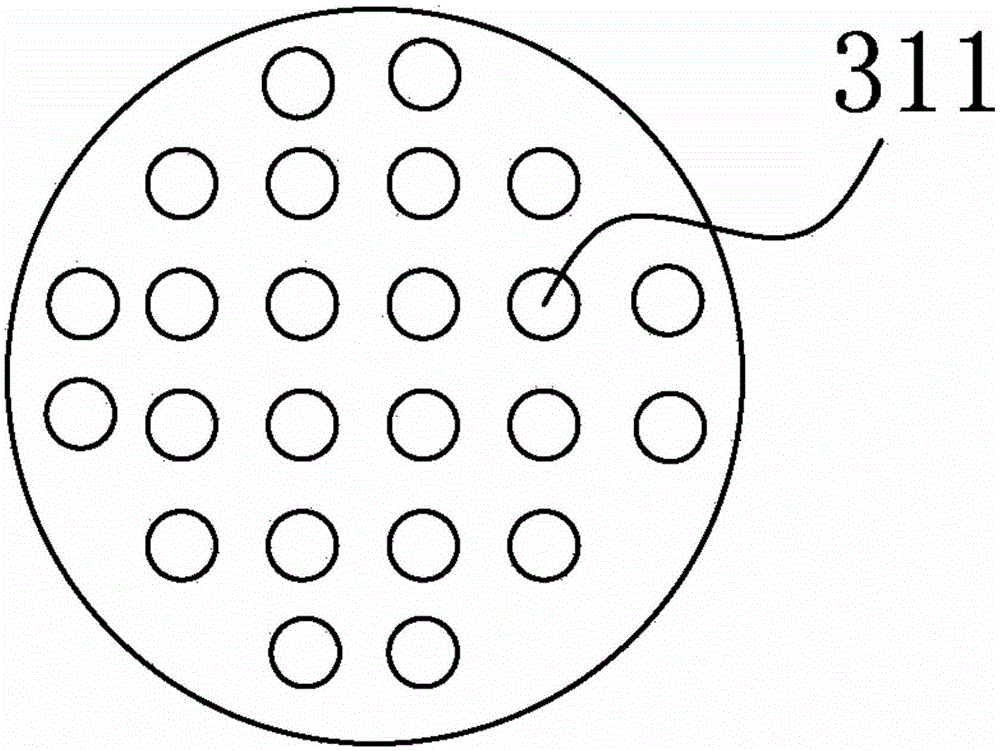

[0013] Such as Figure 1-2 As shown, a special tank for cheese whey includes a tank body 1 with a feeding port 10 on the top. The tank body 1 is provided with a stirring paddle 2 and a filter mechanism 3, and the filter mechanism 3 includes a support plate 31 and the non-woven filter mesh 32 provided on the support plate 31. Preferably, the aperture of the non-woven filter mesh 32 is 40-80 mesh, and the support plate 31 is a stainless steel plate, which acts as a mechanism for the non-woven filter mesh 32 The effect of reinforcement is to prevent the non-woven filter mesh 32 from deforming when compressed; the edge of the support plate 31 is sealed with the inner wall of the tank body 1, and the support plate 31 is provided with a number of small holes 311, and the bottom of the tank body 1 is also provided A low-point discharge valve 4, which can be any of a ball valve, a stop valve, and a diaphragm valve.

[0014] The outer wall of the tank body 1 is also provided with a steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com