Design method for continuously variable transmission device

A design method and technology of continuously variable transmission, applied in the direction of transmission, power device, pneumatic power device, etc., can solve the problems of slippage between the bevel wheel and the metal belt or chain, and the transmission torque of the continuously variable transmission is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

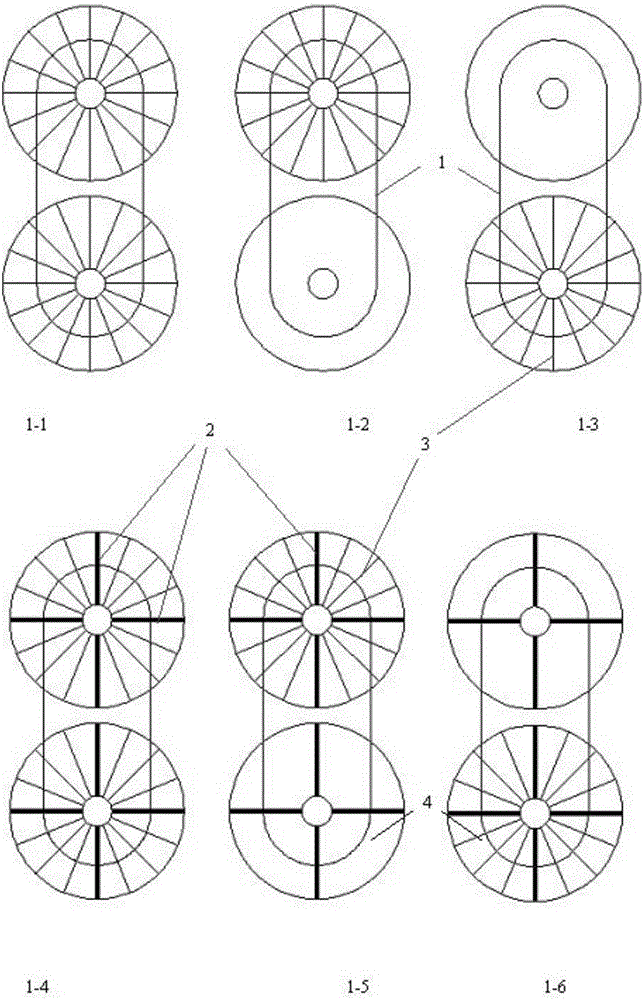

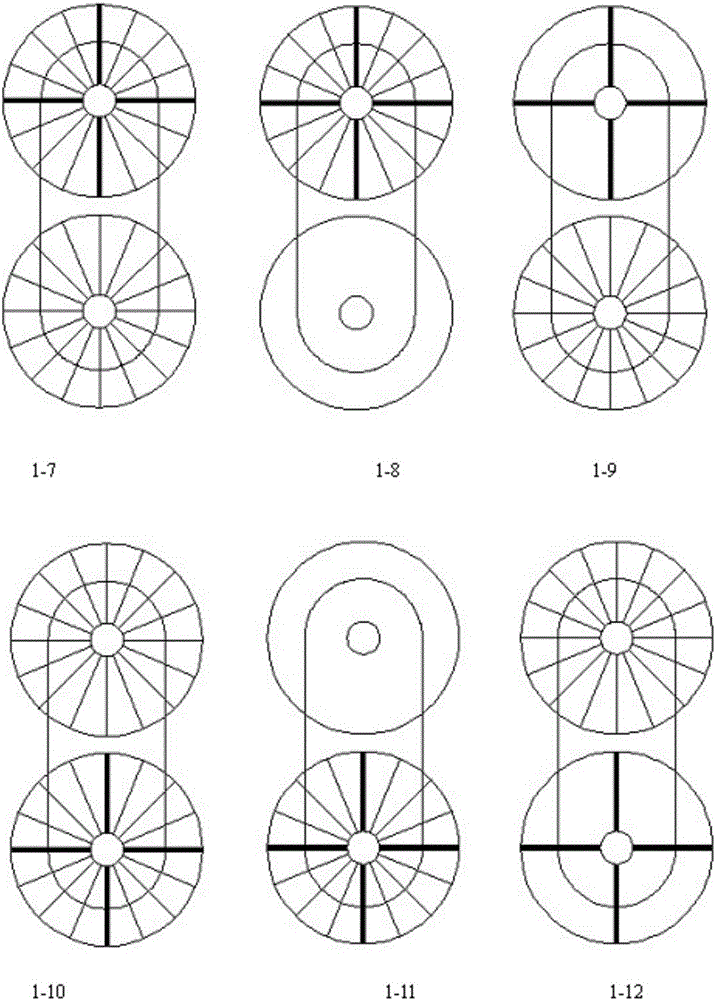

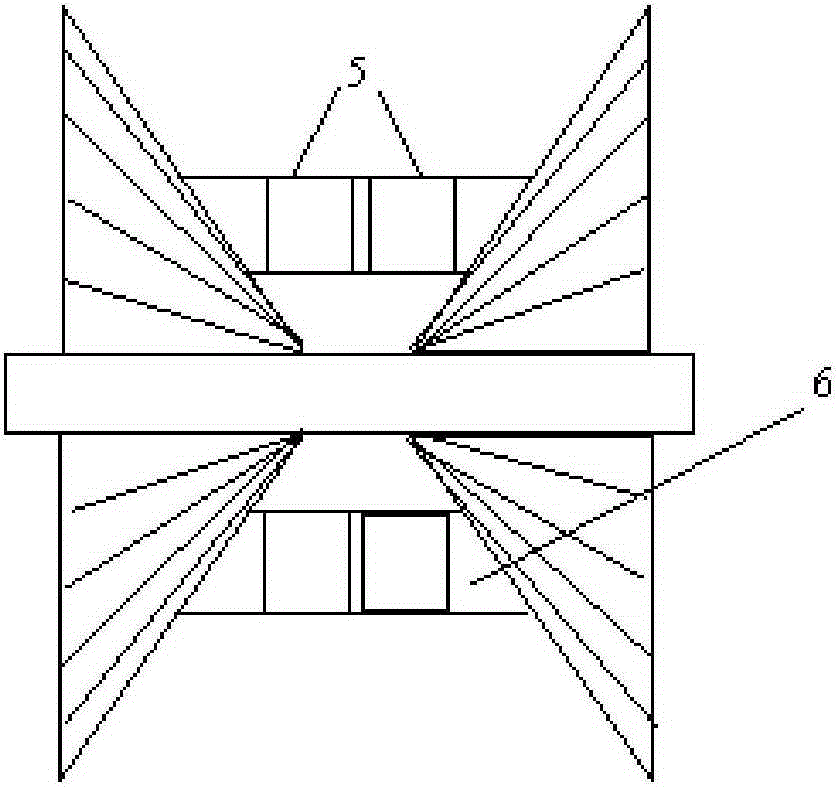

[0017] Examples of the present invention figure 1 , figure 2 , image 3 Shown.

[0018] The present invention is innovatively improved on the basis of the metal belt or metal chain continuously variable transmission. The conical surface of the bevel wheel is designed as a pyramid surface to increase the friction between the metal belt or chain and the bevel wheel, such as figure 1 Shown. The pyramid surface can increase the friction between the metal belt or chain and the bevel wheel through the equidistant ridge line, thereby reducing the slipping phenomenon in the transmission process, and can increase the torque of the continuously variable transmission, and improve its power transmission capacity .

[0019] The edge angle of the two adjacent planes of the pyramid surface is 175 0 -178 0 , The cone angle between two adjacent edges is 22.5 0 . The cone angle determines the number of planes that make up the pyramid surface. The number of planes should not be too much. Too much ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com