Lever cylinder for fixture

A lever cylinder and fixture technology, applied in the field of fixture cylinders, can solve the problems of straight cylinders not being able to output greater clamping force, multiple spaces, and iron filings scalding the air pipe, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

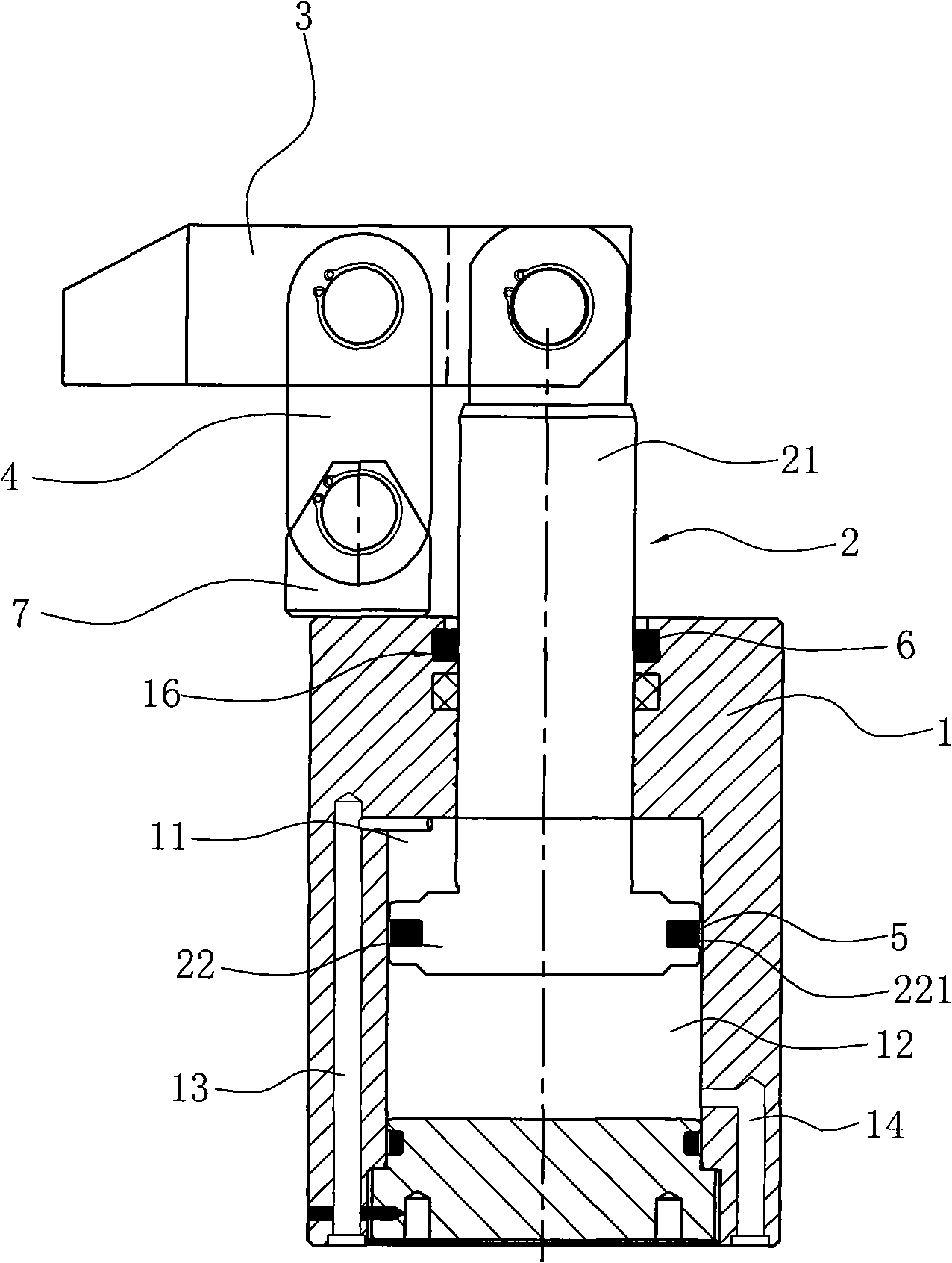

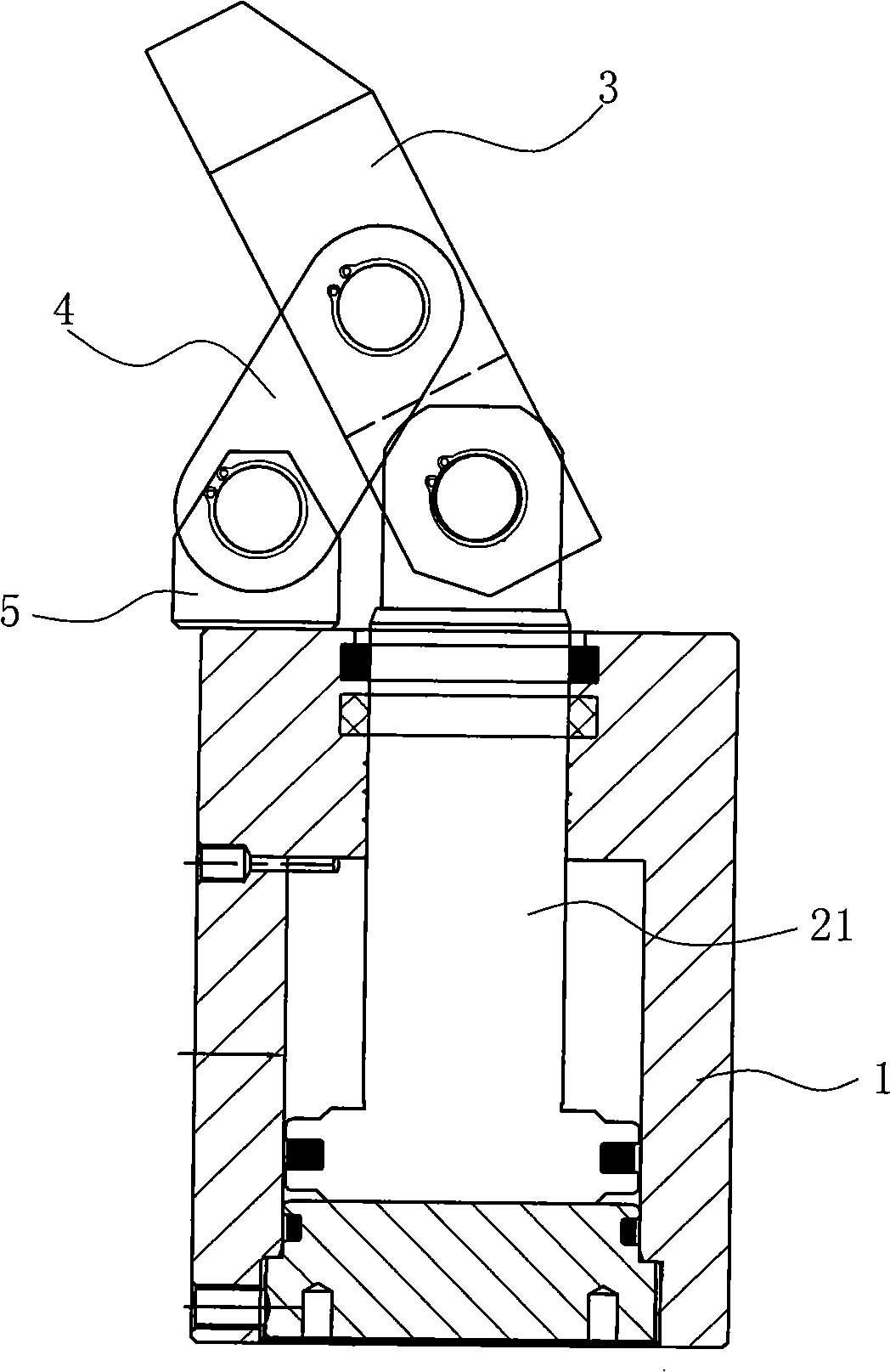

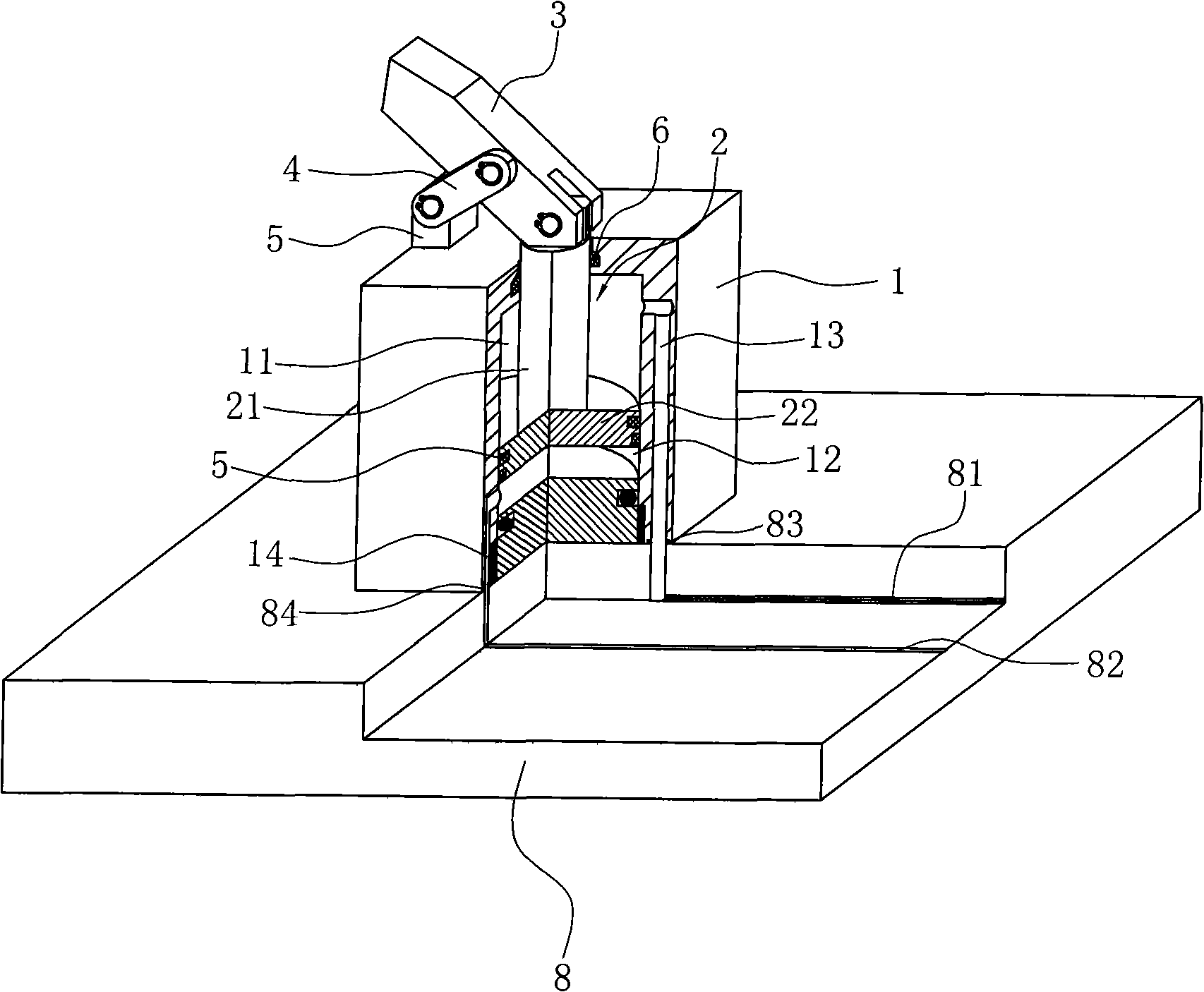

[0022] Such as figure 1 , 2 , 3 shows the first embodiment of the present invention.

[0023] A lever cylinder for clamps, comprising a cylinder body 1, a piston rod 2 installed in the cylinder body 1, a rod portion 21 of the piston rod 2 protruding from the cylinder body 1, and a gap between the piston portion 22 of the piston rod 2 and the inner wall of the cylinder body 1 There is a first sealing ring 5 for sealing, the first sealing ring 5 is installed on the annular groove 221 of the outer peripheral surface of the piston part 22, and a second sealing ring 6 is also arranged between the rod part 21 of the piston rod 2 and the inner wall of the cylinder body 1 for sealing. , the second sealing ring 6 is installed on the annular groove 16 of the inner peripheral surface of the axial through hole of the cylinder body 1, so as to fully ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com