Epoxy resin modified waterborne polyurethane flame retardant paint and preparation method thereof

A water-based polyurethane and epoxy resin technology, used in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve the problems of water resistance, low hardness and low surface gloss of water-based polyurethane flame-retardant coatings. Long fire resistance, good flame retardancy and less smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Synthesis of epoxy resin modified waterborne polyurethane

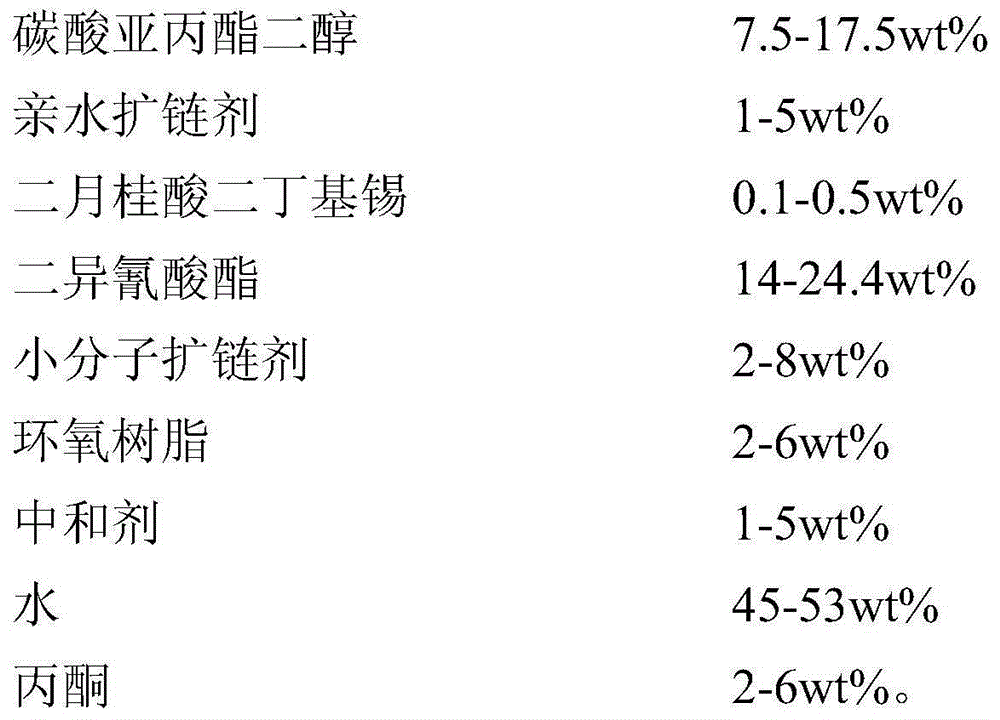

[0030] In a five-neck flask equipped with a stirrer, a thermometer, a condensing device and a nitrogen protection, add pretreated 7.5wt% propylene carbonate diol, stir and heat up to 50°C, add 2wt% sodium ethylenedisulfamate Chain extender and 0.1wt% catalyst dibutyltin dilaurate and 24.4wt% toluene diisocyanate, heat up to 70°C and react for 1.5h, then slowly add 2wt% ethylene glycol chain extender compound, keep 80°C for reaction 0.5h, when the reaction is halfway through the chain extension stage, add 6wt% epoxy resin E-51 and keep it at 70°C for 0.5h; then cool down to room temperature, add 3wt% ammonia water dropwise for neutralization, and the titration time is controlled at After 15 minutes, add 53wt% water and 2wt% acetone to the prepolymer for emulsification, vigorously stir for 30 minutes, vacuum reduce and evaporate the acetone to obtain an epoxy resin modified waterborne polyurethane coating.

...

Embodiment 2

[0036] 1. Synthesis of epoxy resin modified waterborne polyurethane

[0037] In a five-necked flask equipped with a stirrer, a thermometer, a condensing device and a nitrogen protection, add pretreated 17.5wt% propylene carbonate diol, stir and heat up to 55°C, add 1wt% adipic acid dihydrazide Chain extender and 0.5wt% catalyst dibutyltin dilaurate and 14wt% 4,4-diphenylmethane diisocyanate, after heating up to 80°C for 3 hours, slowly add metered amount of 8wt% butanediol chain extender Compound, kept at 70°C for 0.8h. When the reaction was halfway through the chain extension stage, 4wt% epoxy resin 711 was added, and kept at 80°C for 1h; then cooled to room temperature, and 1wt% triethylamine was added dropwise for neutralization. After the titration time was controlled at 20 minutes, 49 wt % water and 5 wt % acetone were added to the prepolymer for emulsification, vigorously stirred for 30 min, and the acetone was evaporated under vacuum to obtain an epoxy resin modified wa...

Embodiment 3

[0044] 1. Synthesis of epoxy resin modified waterborne polyurethane

[0045]In a five-neck flask equipped with a stirrer, thermometer, condensing device and nitrogen protection, add pretreated 13.5wt% polypropylene carbonate diol, stir and heat up to 60°C, add 5wt% 2,2-bis Methylol propionic acid chain extender and 0.3wt% catalyst dibutyltin dilaurate and 19.2wt% diisocyanate including isophorone diisocyanate, after heating up to 85°C for 2 hours, slowly add quantitative 4wt% of small molecules For the chain extender compound, keep the reaction at 85°C for 1h. When the reaction is halfway through the chain extension stage, add 2wt% epoxy resin and keep it at 85°C for 0.8h; After neutralization, the titration time is controlled at 30 minutes, and then 45 wt % of water and 6 wt % of acetone are added to the prepolymer for emulsification, vigorously stirred for 30 min, and the acetone is removed by vacuum reduction to obtain an epoxy resin modified waterborne polyurethane coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com