Composite biodegradation gas-phase anti-rusting membrane and preparation process thereof

A gas-phase anti-rust and biodegradation technology, applied in the field of composite biodegradable gas-phase anti-rust film and its preparation process, can solve the problems of large impact, anti-rust oil failure, environmental protection, etc., to achieve inhibition of electrochemical reactions, high barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

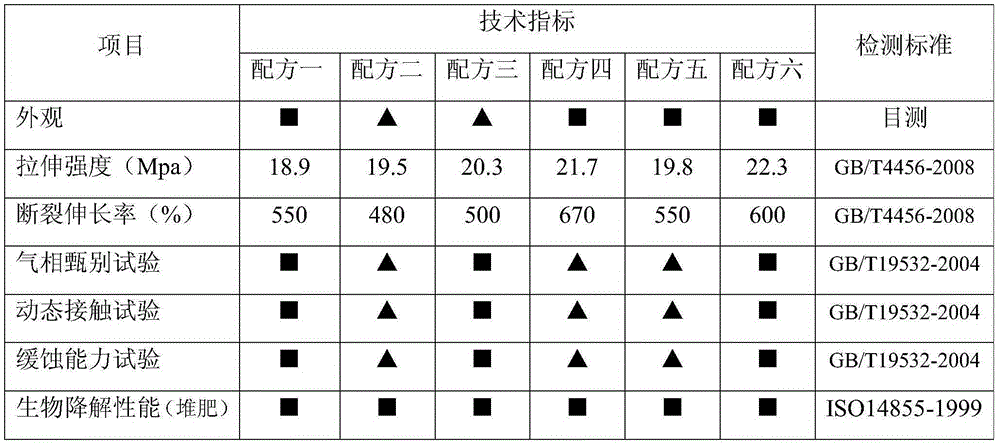

Examples

Embodiment Construction

[0020] Embodiment The preparation of antirust film of the present invention

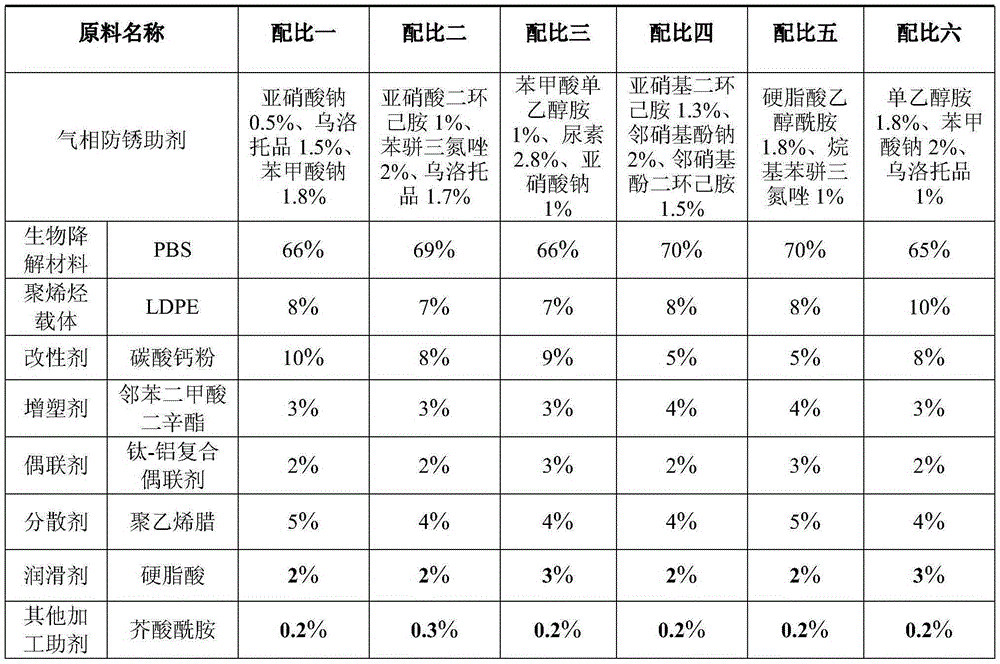

[0021] 1. Raw material ratio (by mass percentage) is shown in Table 1.

[0022] Table 1 raw material ratio

[0023]

[0024] 2. Granulation

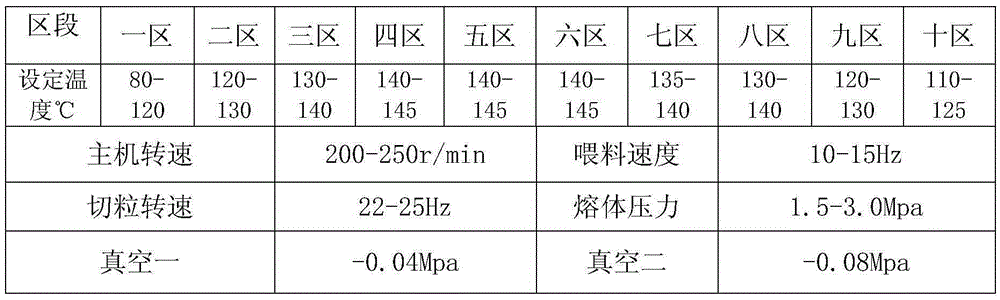

[0025] Pour the raw materials of the above formula into the high-speed mixer according to the ratio, control the stirring speed at 450-480 rpm, stir for 3-5 minutes, do operations such as shoveling the edge, shoveling the bottom and discharging water vapor, and then control the stirring speed at 900-960 Turn, stir for another 10 minutes, knead the uniformly stirred mixture in a 75-type twin-screw machine, finally extrude and granulate, and screen to obtain a composite biodegradable vapor phase antirust film masterbatch. The granulation process settings are shown in Table 2.

[0026] Table 2 Granulation process settings

[0027]

[0028] 3. Film blowing

[0029] Utilize the existing single-screw machine or three-layer co-extrusion equipment to extrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com