A kind of PBT heat-conducting, heat-resistant material for LED lamp holder and preparation method thereof

A technology of LED lamp holder and heat-resistant material, applied in the field of PBT thermal conductivity, heat-resistant material and its preparation, can solve the problems of reduced external luminous efficiency and poor light transmittance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

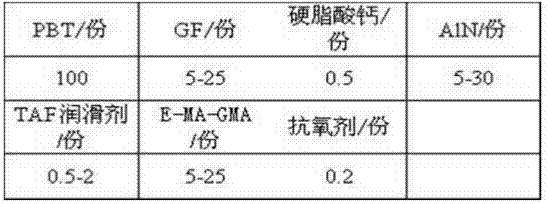

Method used

Image

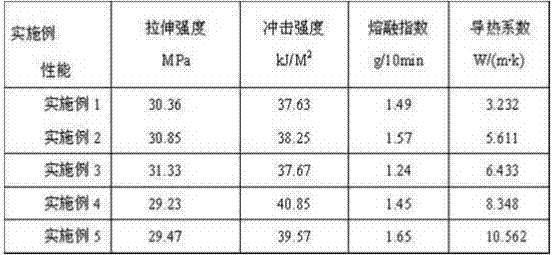

Examples

Embodiment 1

[0018] Heat the glass fiber in a muffle furnace for dewaxing, add 1% silane coupling agent by mass fraction into the water-ethanol mixture and soak for 2 hours, then wash it, and dry it in an oven at 80 degrees Celsius for 3 hours for later use; PBT, E -MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, and calcium stearate were mixed in a high-speed mixer at a ratio of 100:15:2:10:1:0.5 and mixed for 10 minutes, then dried in an oven at 80°C for 1 Standby for one hour; add dried PBT, E-MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, calcium stearate into the extruder, and then add 20 parts of treated Glass fiber, extruded and granulated to obtain heat-conducting and heat-resistant PBT materials.

Embodiment 2

[0020] Heat the glass fiber in a muffle furnace for dewaxing, add 1% silane coupling agent by mass fraction into the water-ethanol mixture and soak for 2 hours, then wash it, and dry it in an oven at 80 degrees Celsius for 3 hours for later use; PBT, E -MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, and calcium stearate were mixed in a high-speed mixer at a ratio of 100:15:2:15:1:0.5 and mixed for 10 minutes, then dried in an oven at 80°C for 1 Standby for one hour; add dried PBT, E-MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, calcium stearate into the extruder, and then add 20 parts of treated Glass fiber, extruded and granulated to obtain heat-conducting and heat-resistant PBT materials.

Embodiment 3

[0022] Heat the glass fiber in a muffle furnace for dewaxing, add 1% silane coupling agent by mass fraction into the water-ethanol mixture and soak for 2 hours, then wash it, and dry it in an oven at 80 degrees Celsius for 3 hours for later use; PBT, E -MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, and calcium stearate were mixed in a high-speed mixer at a ratio of 100:15:2:20:1:0.5 and mixed for 10 minutes, then dried in an oven at 80°C for 1 Standby for one hour; add dried PBT, E-MA-GMA, TAF lubricant, AlN powder, antioxidant 1010, calcium stearate into the extruder, and then add 20 parts of treated Glass fiber, extruded and granulated to obtain heat-conducting and heat-resistant PBT materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com