Catalyst for ring-opening copolymerization of oxyalkylene and lactide

A technology for oxidizing alkene and lactide, applied in the field of catalysts, can solve the problems of low activity, long copolymerization reaction time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

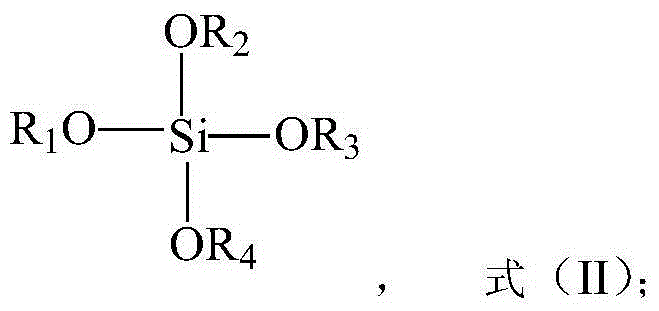

[0029] 1. Preparation of double metal cyanide complex catalyst

[0030] 8 g of potassium hexacyanocobaltate was dissolved in 140 ml of distilled water. Slowly add 38.5% (weight) of ZnCl at 8000 rpm 2 65 grams of aqueous solution, followed by adding a mixture of 100 milliliters of tert-butanol and 100 milliliters of distilled water. After stirring for 20 minutes, add 10.8 grams of methyl orthosilicate and 200 milliliters of distilled water. After stirring for 10 minutes, vacuum filter with a sand core funnel. Add 150 milliliters of tert-butanol and 60 milliliters of distilled water to the obtained solid, stir at a speed of 8000 rpm for 10 minutes, then add 7.8 grams of methyl orthosilicate, stir for 10 minutes, and centrifuge. Add 200 ml of tert-butanol to the obtained solid, stir at 8000 rpm for 20 minutes, and centrifuge. The solid was vacuum-dried at 60°C until constant weight to obtain 11.7 g of solid powder catalyst I.

[0031] After analysis: Co9.0% (weight) Zn23.8% (w...

Embodiment 2

[0036] 1. Preparation of double metal cyanide complex catalyst

[0037] With embodiment 1.

[0038] 2. Preparation of copolymer

[0039] 30g starter polyoxypropylene glycol (M n 400) and 0.0072g of the above-mentioned catalyst I were added to a pressure-resistant reactor equipped with a stirring paddle, and the reactor was alternately replaced with vacuum and nitrogen for 3 to 5 times. After the temperature was raised to 105°C, 20g of propylene oxide was added to pre-activate the catalyst. . After the pressure in the reactor is significantly lowered, first add 160g of a mixture consisting of 120g of propylene oxide and 40g of L-lactide to the reactor continuously, and then continuously add 30g of propylene oxide after this step is completed. It takes 2 hours hour, the reaction temperature is controlled at 135-140° C., the reaction pressure is lower than 1 MPa, and the stirring and aging are continued for 1 hour after the feeding is completed. In this embodiment, the amount...

Embodiment 3

[0041] 1. Preparation of double metal cyanide complex catalyst

[0042] With embodiment 1.

[0043] 2. Preparation of copolymer

[0044] 30g starter polyoxypropylene glycol (M n 700), 70g of L-type lactide and 0.009g of the above-mentioned catalyst I were added to a pressure-resistant reactor equipped with a stirring paddle, and the reactor was alternately replaced with vacuum and nitrogen for 3 to 5 times. The mixture composed of propylene oxide and 20g L-type lactide is used to preactivate the catalyst. After the pressure in the reactor is significantly reduced, the remaining mixture is continuously added to the reactor within 2 hours, and the reaction temperature is controlled at 140-145 °C, the reaction pressure is lower than 1 MPa, and the stirring is continued for 1 hour after the addition is completed. The consumption of DMC catalyst is 30ppm among the present embodiment. The number average molecular weight M of the polymer product obtained by GPC testing n for 764...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com