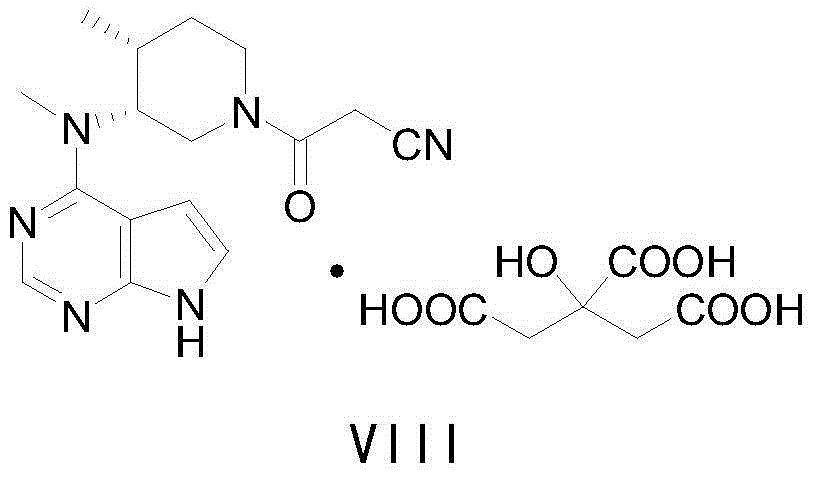

Preparation method of (3R,4R)-(1-benzyl-4-methylpiperidine-3-yl)methylamine-L-di-p-toluoyltartaric acid salt

A technology of toluoyl tartrate and methylpiperidine, applied in the field of organic chemistry, can solve the problems of difficult reaction conditions, high catalyst cost, expensive starting materials, etc., and achieve low cost, high total yield, and easy industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

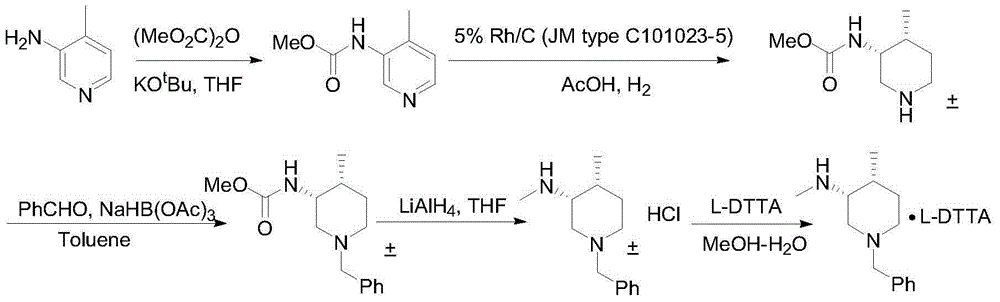

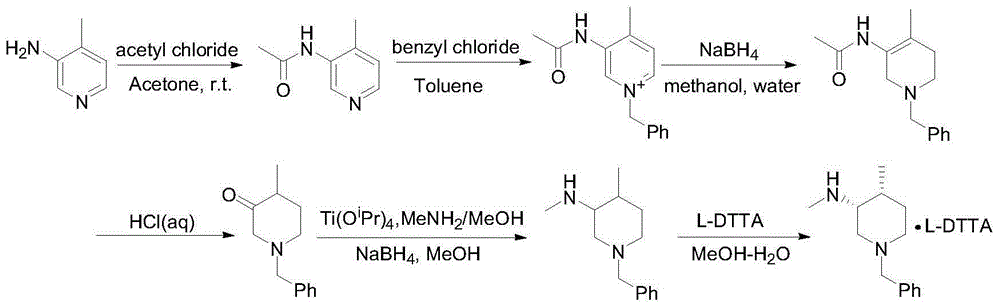

Method used

Image

Examples

Embodiment 1

[0027] 1kg of formula I compound N-benzyl-4-carbonyl-3-piperidinecarboxylic acid ethyl ester was added in 7kg of ethanol, then 0.9kg of 25% ammonia water was added, the reaction temperature was 33°C, and after 22 hours of reaction, the Most of the ethanol was concentrated under pressure, and 7kg of methyl tert-butyl ether was added for extraction, and the separated organic phase was dried with sodium sulfate for 3 hours, and sodium sulfate was filtered off to obtain the methyl tert-butyl ether of the compound of formula II solution.

[0028]Cool the methyl tert-butyl ether solution of the compound of formula II obtained in the previous step to -55°C, and under the protection of nitrogen, add 2.5 L of 2mol / L tetrahydrofuran solution of methyl Grignard reagent dropwise, and the dropwise addition is completed in 1 hour. The temperature of the system is at -27°C. After reacting for 5 hours, slowly add 3.5 liters of 10% ammonium chloride solution dropwise to terminate the reaction,...

Embodiment 2

[0034] Add 20kg of ethanol in 3kg of formula I compound N-benzyl-4-carbonyl-3-piperidinecarboxylic acid ethyl ester, then add 3.9kg of 25% ammonia water, the reaction temperature is 30 ℃, after reacting for 30 hours, reduce Most of the ethanol was concentrated under pressure, and 20kg of methyl tert-butyl ether was added for extraction, and the separated organic phase was dried with sodium sulfate for 5 hours, and sodium sulfate was filtered off to obtain the methyl tert-butyl ether of the compound of formula II solution.

[0035] Cool the methyl tert-butyl ether solution of the compound of formula II obtained in the previous step to -60°C, and under the protection of nitrogen, add 8.6L 2mol / L of the tetrahydrofuran solution of methyl Grignard reagent dropwise, and the dropwise addition is completed in 1.5 hours. The temperature of the system is at -30°C. After reacting for 7 hours, slowly drop 10 liters of 10% ammonium chloride solution to terminate the reaction, separate the...

Embodiment 3

[0041] 5kg of formula I compound N-benzyl-4-carbonyl-3-piperidinecarboxylic acid ethyl ester was added in 35kg of ethanol, then 2.6kg of 25% ammonia water was added, and the reaction temperature was 40°C. After 16 hours of reaction, the Most of the ethanol was concentrated under pressure, and 35kg of methyl tert-butyl ether was added for extraction, and the separated organic phase was dried with sodium sulfate for 5 hours, and sodium sulfate was filtered off to obtain the methyl tert-butyl ether of the compound of formula II solution.

[0042] Cool the methyl tert-butyl ether solution of the compound of formula II obtained in the previous step to -40°C, and under nitrogen protection, add 10.5 L of 2 mol / L tetrahydrofuran solution of methyl Grignard reagent dropwise, and the dropwise addition is completed in 2 hours. The temperature of the system is at -20°C. After reacting for 4 hours, slowly add 17 liters of 10% ammonium chloride solution dropwise to terminate the reaction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com