Production line of resin type diamond wire saw

A diamond wire saw and resin type technology, which is applied to metal sawing equipment, tools for sawing machines, tool manufacturing for sawing machines, etc. The effect of application value, controllable quality and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] At present, due to the limitation of the electroplating process, the electroplating process takes a long time, low efficiency, and high cost. Therefore, more research is needed on the production technology of resin-type diamond wire saws to design a more practical and economical manufacturing method.

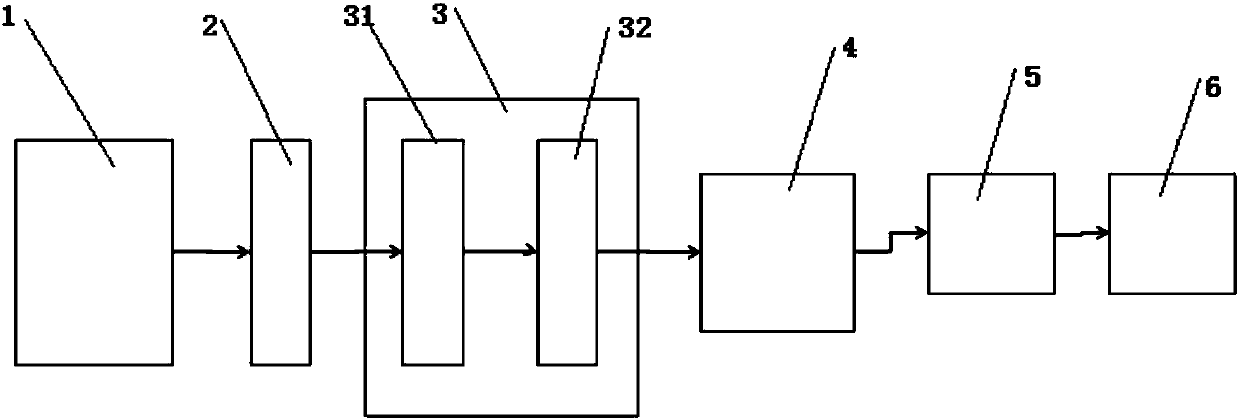

[0021] like figure 1 As shown, the invention provides a production line of resin type diamond wire saw, comprising:

[0022] Base material selection device 1: It is used to automatically select metal wires with a diameter ranging from 0.35 to 0.5 mm as the base material. Both ends of the metal wires have welding joints, and the metal wires are connected by welding through welding joints;

[0023] Solder joint automatic detection device 2: used to test the tensile strength and fatigue life of the weld of the metal wire welded through the welded joint;

[0024] Surface pretreatment device 3: used to perform surface pretreatment on the metal wires that pass the solder joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com