Two-gear four-wheel hydraulic stepless variable speed drive axle assembly for large harvester

A technology of hydraulic continuously variable transmission and drive axle assembly, which is applied in the direction of control devices, transportation and packaging, vehicle parts, etc., which can solve the problems of complex operation, high energy consumption, and large volume, and achieve the effect of simple operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

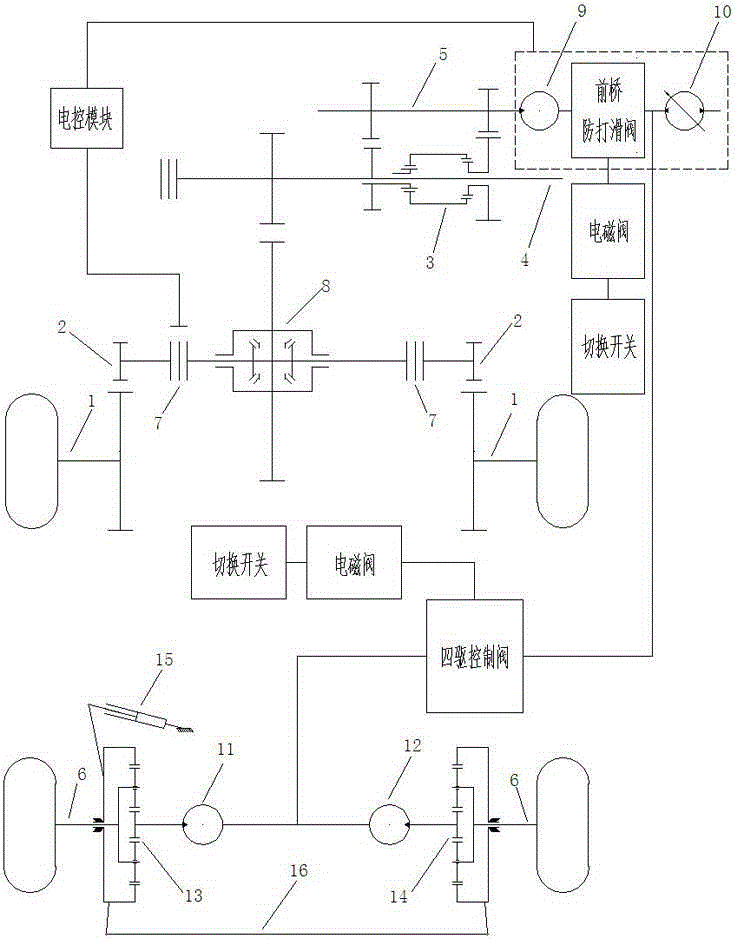

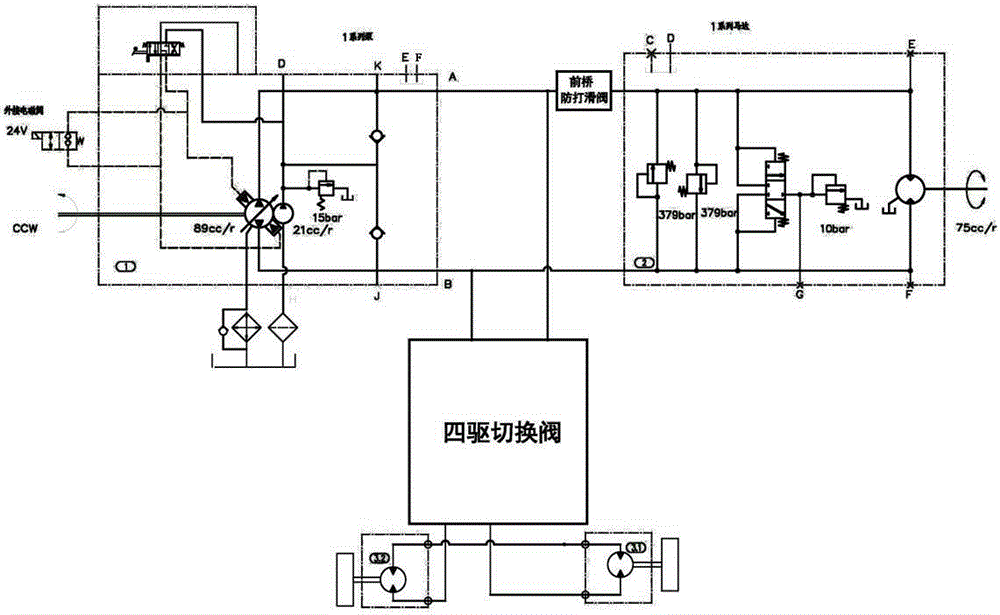

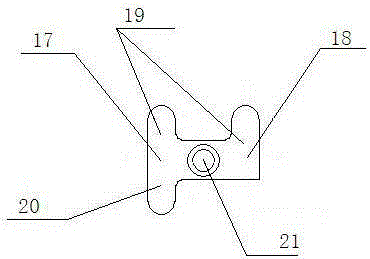

[0020] The patent of the present invention mainly provides the power input by the hydraulic variable pump 10, drives the hydraulic quantitative motor 9 to rotate at variable speeds, and selects the transition gear 18 and the harvesting gear 17 of the front axle assembly through the gear shifting sleeve 3 of the mechanical gearbox. , so that the front drive axle assembly drives the harvester to realize actions such as forward, backward, steering and continuously variable speed change. When the harvester requires the rear drive steering axle to be driven in parallel with the front axle, the switch is turned on to control the solenoid valve to switch to the four-wheel drive state, so that the left rear axle cycloidal motor 11 and the right rear axle cycloidal motor 12 are incorporated into the hydraulic system. When the harvester does not need four-wheel drive, the rear axle drive system can be cut off by a switch, and the rear axle cycloidal motors 11 and 12 are in the follow-up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com