Equal-polar-angle gear slotting method of gear blanks of non-circular gears

A non-circular gear, equal polar angle technology, applied in the field of gear manufacturing, can solve the problems of low efficiency, difficult to process non-circular helical gears, difficult to implement, etc., to achieve increased operation speed and accuracy, efficient and high-precision machining, and reduce error sources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

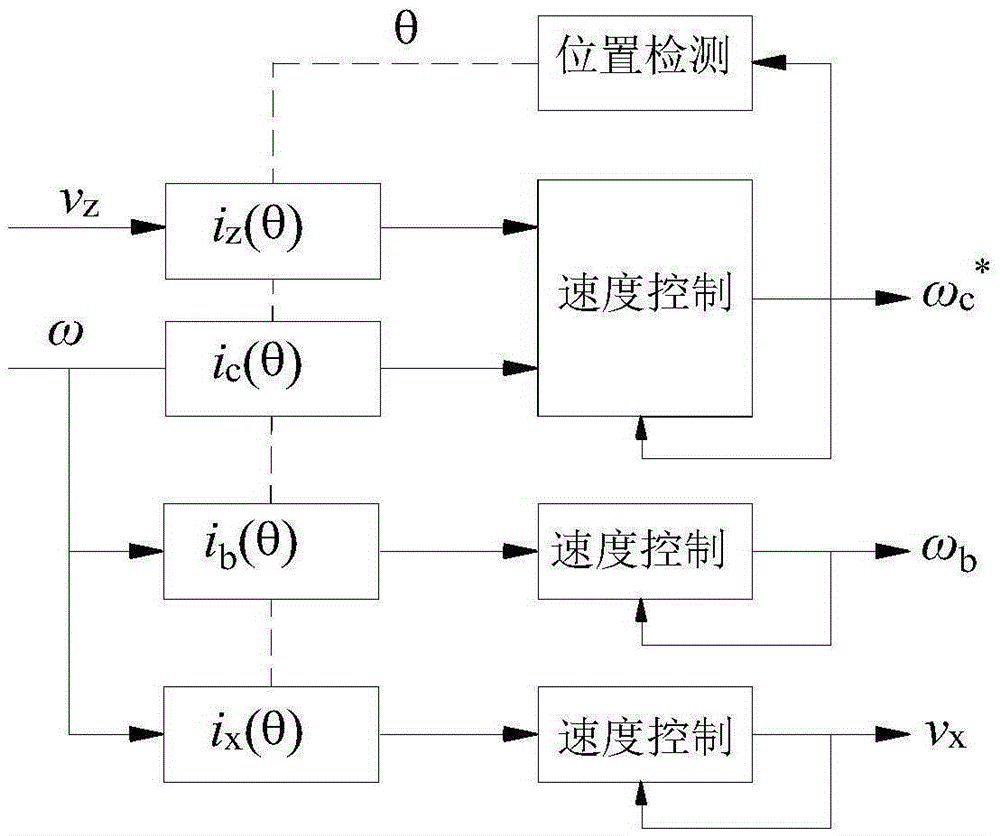

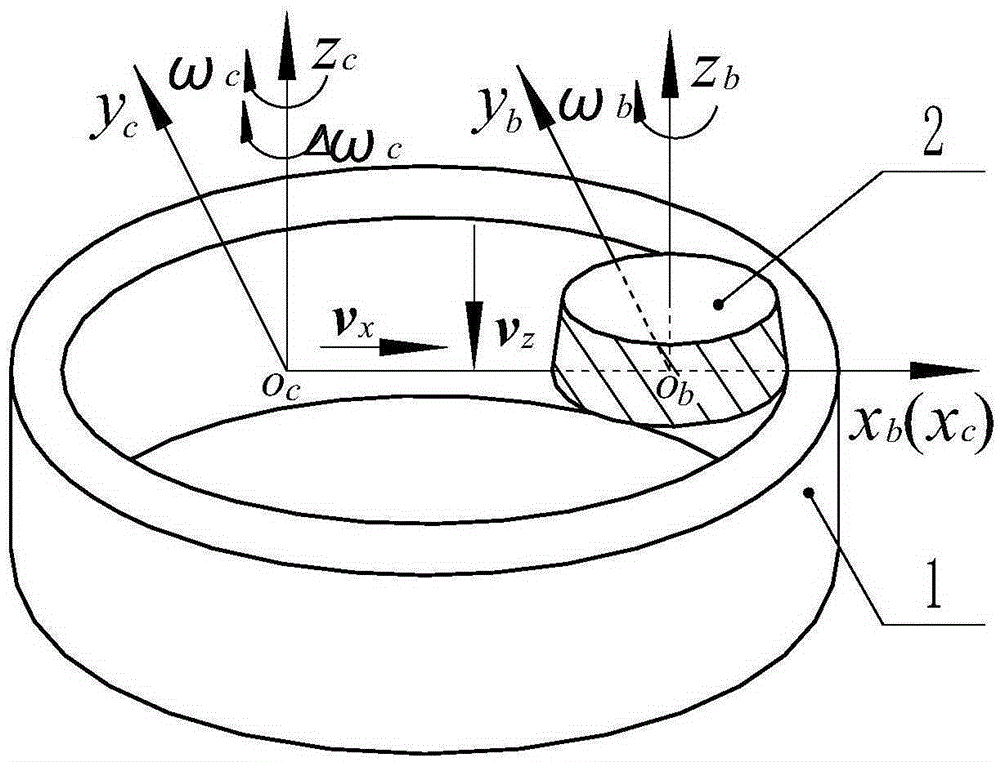

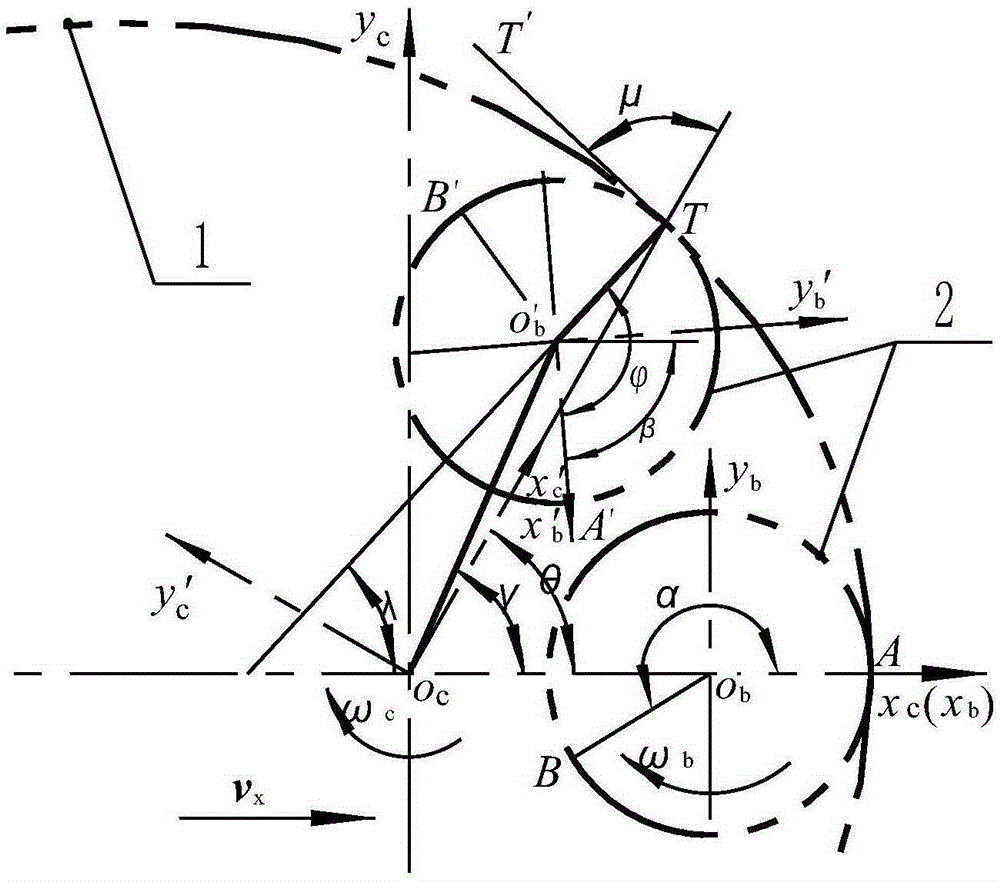

[0034] see figure 2 , which shows the interlocking relationship of each axis in the method for inserting non-circular gears with equal polar angles of the gear blank in the present invention. In the end face of the gear blank 1, the gear shaping cutter 2 is ω b rotation, gear blank 1 with ω c Rotation, in order to ensure the pure rolling of the 2 pitch circle of the gear shaper cutter and the 1 pitch curve of the gear blank in the same direction during the slotting process, within the end surface of the gear blank 1, ω b with ω c Maintain a strict transmission ratio according to the requirements of generating motion. In the axial plane of the gear blank 1, in order to maintain the inscribed contact between the pitch circle of the gear shaping cutter 2 and the curve of the gear blank 1 pitch, the gear shaping cutter 2 acts as v x Movement, axial reciprocating slotting v z , so that all teeth are slotted, in order to ensure uniform precision of the tooth surface along the ...

Embodiment 2

[0042] The method of the present invention slots the internal meshing third-stage elliptical helical gear, and the rest is the same as the first embodiment, the difference is that the tooth blank 1 speed ω c Additional rotary motion Δω c , the linkage equation of internal meshing slotting non-circular helical gear is:

[0043] v x = r d r d θ - r b j s i n μ d r d θ - rr b j ...

Embodiment 3

[0049] see Figure 7 , which shows the interlocking relationship of each shaft on the end surface of the tooth blank in the method of inserting the externally meshing non-circular gear with equal polar angles of the tooth blank in the present invention. The rest is the same as the first embodiment, the difference is that the gear shaper cutter 2 is located outside the curve of the first pitch of the gear blank, and the rotation direction of the two is opposite. Based on the above method and according to the principle of differential geometry, the linkage equation of external meshing non-circular spur gear is established as follows:

[0050] v x = r d r d θ + r b j ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com