A method for equal rotation angle slotting of non-cylindrical gear blanks

A non-cylindrical, equal-angle technology, applied in the field of corner slotting, can solve the problems of not being able to process internal meshing non-cylindrical gears, tooth profile overcut deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

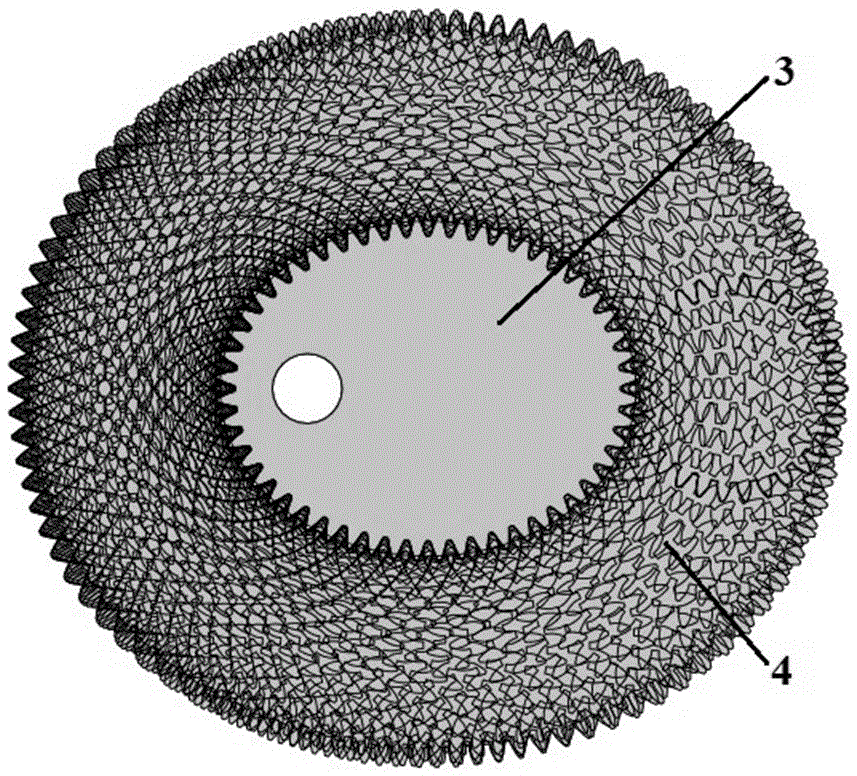

[0095] see image 3 , in order to adopt the method of the present invention to slot the external meshing elliptical spur gear tool position track sectional view, the pitch curve equation of the external meshing elliptic spur gear is,

[0096] r = a ( 1 - e 2 ) 1 - e cos ( n θ ) - - - ( 25 )

[0097] The workpiece to be processed is an external meshing elliptical spur gear, and its parameters are as follows: semi-major axis a=146.880mm, order n=1, tooth width b=50mm, eccentricity e=0.6, normal modulus m n =5mm, the number ...

Embodiment 2

[0099] see Figure 4 , for adopting the method of the present invention to insert the three-dimensional view of the external meshing right-handed elliptical helical gear tool position trajectory, the external meshing elliptical helical gear pitch curve equation is the same as formula (25), and the difference between it and the external meshing elliptical spur gear is that there is a certain helix angle. The workpiece to be processed is an external meshing right-handed elliptical helical gear, and its parameters are as follows: semi-major axis a=150mm, order n=1, tooth width b=50mm, eccentricity e=0.6, normal modulus m n =5mm, helix angle β c =11.912°, the number of gear teeth Z=52, the number of gear teeth z=30, and the polar angle θ∈[0,2π]; using the method of the present invention, in the electronic gearbox, the formula (25) is substituted into the non- The linkage mathematical model of cylindrical helical gear (2), the numerical control system calculates the tool position ...

Embodiment 3

[0101] see Figure 7 , for adopting the method of the present invention to slot the internal meshing elliptic spur gear cutter position trajectory cross-sectional view, the pitch curve equation of the internal meshing elliptic spur gear is the same as formula (25), and the difference between it and the external meshing elliptic spur gear is that the teeth are distributed inside the pitch curve . The workpiece to be processed is an internal meshing elliptical spur gear, and its parameters are as follows: semi-major axis a=147.960mm, order n=1, tooth width b=50mm, eccentricity e=0.6, normal modulus m n =3mm, the number of gear teeth Z=88, the number of teeth of the gear shaping cutter z=20, and the polar angle θ∈[0,2π]. By adopting the method of the present invention, in the electronic gearbox, the formula (25) is substituted into the linkage mathematical model (3) of the internal meshing non-cylindrical spur gear, the numerical control system calculates the tool position track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com