Machining device and method for annular bulge of aluminum alloy conduit connector

A technique for conduit joints and processing devices, which is applied in the field of mechanical manufacturing and processing, can solve problems such as unreasonable structure and design, difficulty in meeting the manufacturing requirements of passenger aircraft, and affecting the processing quality and efficiency of aluminum alloy conduit joint ring protrusions, etc., to achieve The processing method is convenient, the structure is simple, and the effect of being easy to manufacture and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

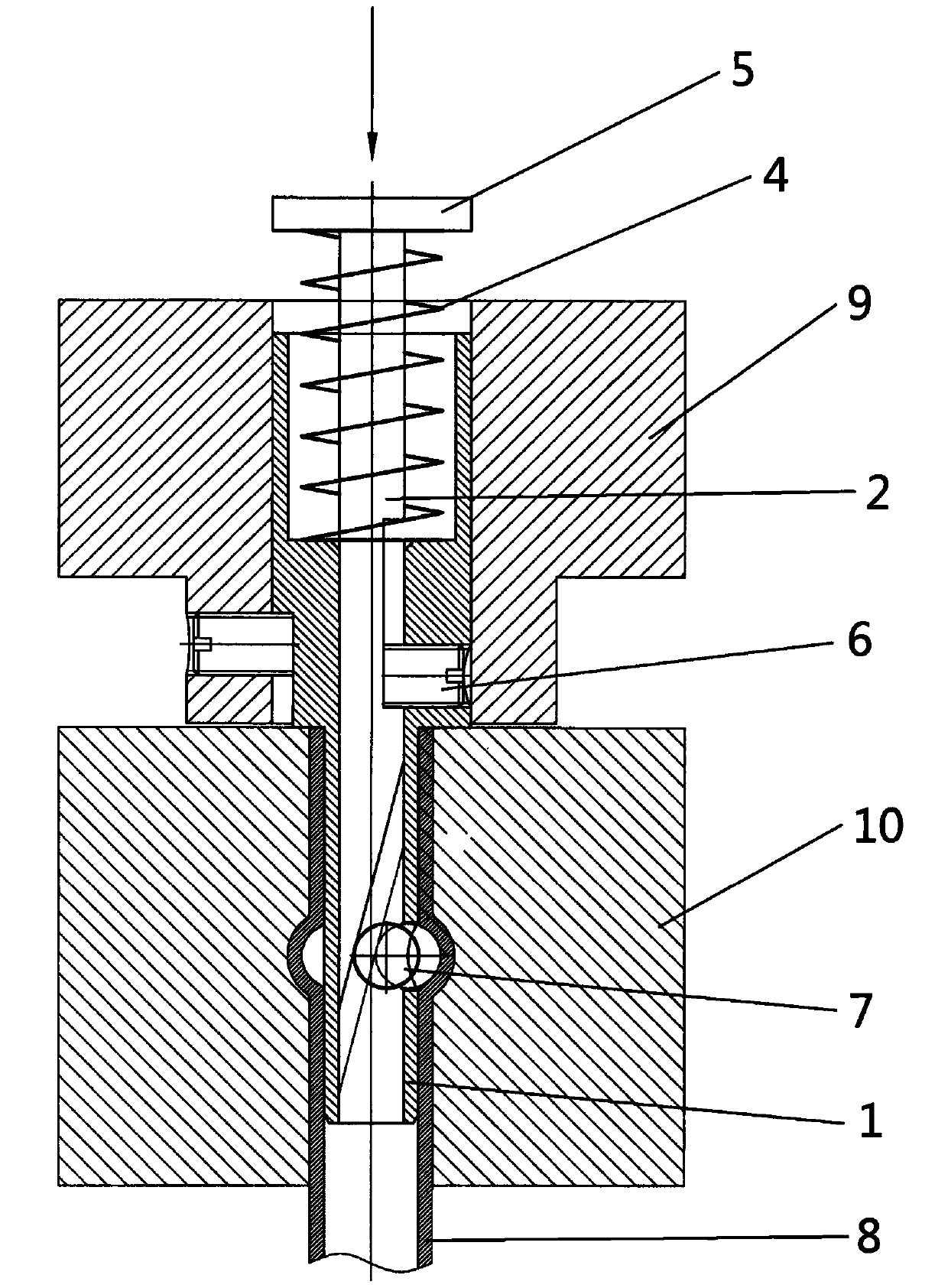

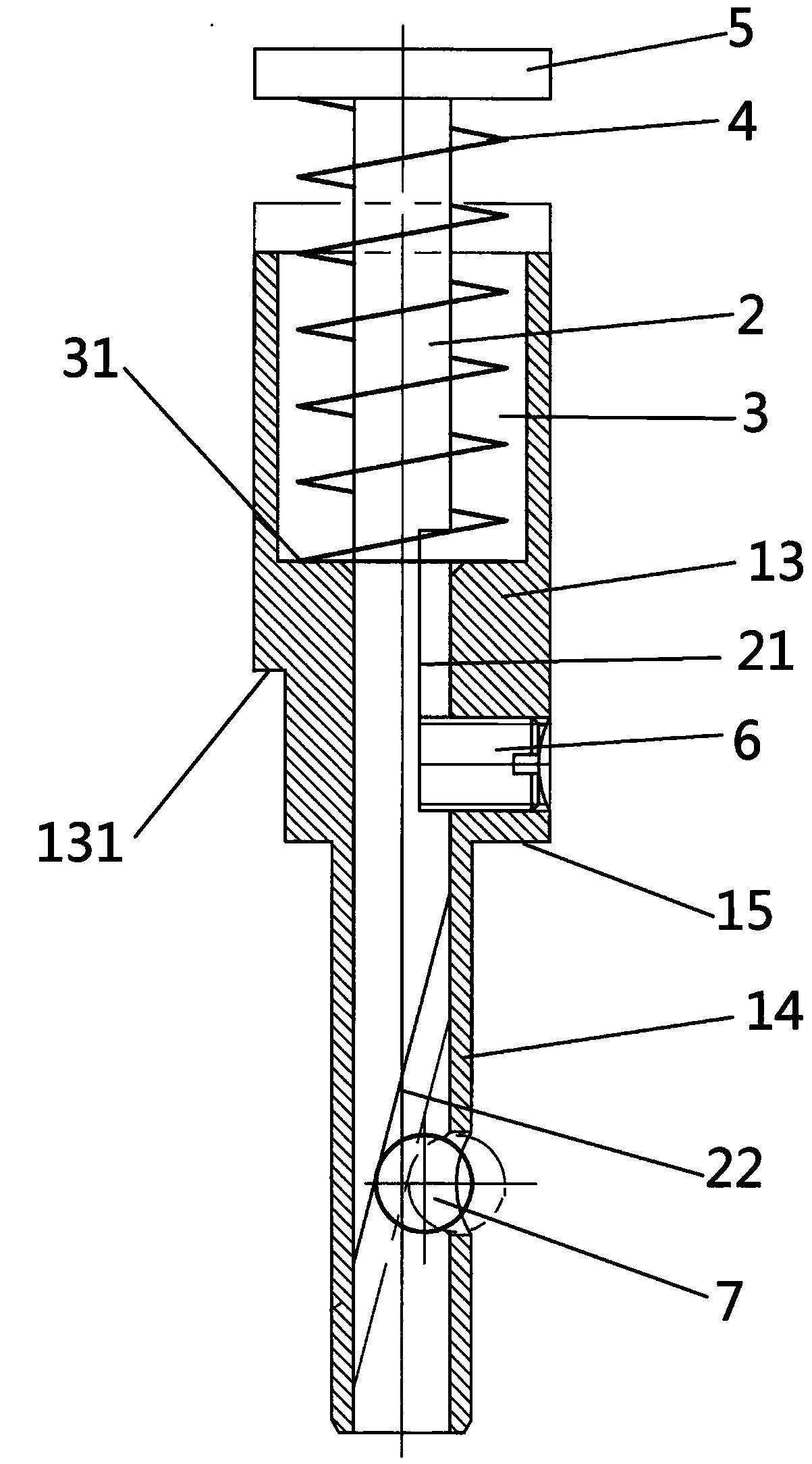

[0025] Such as Figure 1-3 As shown, 1. An aluminum alloy conduit joint ring protrusion processing device has a housing 1, a mandrel 2 placed in the housing 1, a cavity 3 is provided at one end of the housing 1, and a limit spring 4 is placed The concave cavity 3 is sleeved on the mandrel 2, one end of the limit spring 4 is fixedly connected to the bottom 31 of the cavity, and the other end is fixedly connected to the force block 5 at the top of the mandrel 2, and the middle part of the mandrel 2 is provided with Groove 21, the housing 1 corresponding to the groove 21 is provided with an opening I11, the top wire 6 is placed at the opening I11 and fits with the groove 21, the tail end of the mandrel 2 is a slope 22, corresponding to the slope 22 The shell 1 is provided with an opening II12, and the ball 7 is placed at the opening II12 and cooperates with the inclined surface 22.

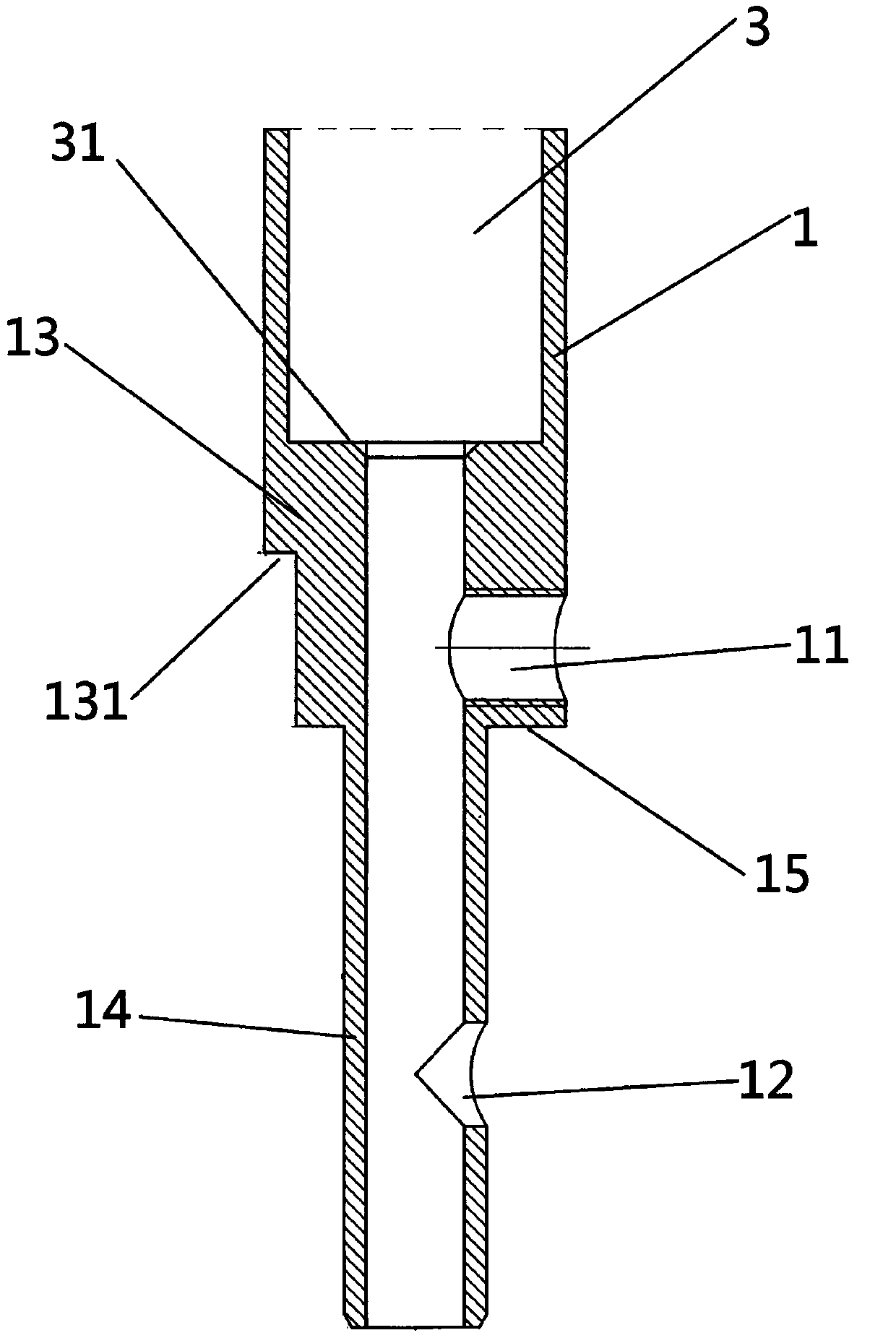

[0026] Such as image 3 The outer wall of the housing 1 shown is divided into a clamping sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com