Preparation method for aluminum alloy semi-solid slurry induced and impregnated by modificator

A semi-solid slurry and aluminum alloy technology, which is applied in the field of metal material preparation, can solve the problems of large equipment investment, stirring dead zone, serious magnetic leakage, etc., and achieve the effects of no three-waste pollution, uniform distribution and fine grain size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

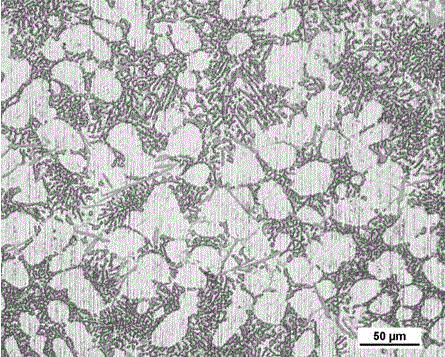

[0017] Put the Al-Si-Cu alloy ingot into a graphite crucible and overheat it to 740 °C to completely melt the aluminum block, then refine and remove slag, and then add a small piece of Al-9Sr master alloy (the mass fraction of Sr is 9wt.%), Prepare the aluminum alloy whose mass fraction of Sr in the melt is 0.01wt.%, then raise the temperature of the furnace to 760°C and keep it warm for 15 minutes, then place the preheated ultrasonic horn probe in the melt, and apply Intermittent ultrasound, the interval between each ultrasound is 1s, the release time of each ultrasound is 2.0s, the ultrasound power is 1.0kw, the ultrasound frequency is 20kHz, the total ultrasound time is 3min, after the ultrasound is finished, it is cooled to 610°C with the furnace and left standing Keep warm for 8 minutes, and then apply intermittent ultrasound to the melt again. The interval between each ultrasound is 1s, the release time of each ultrasound is 2.0s, the ultrasound power is 1.0kw, the ultras...

Embodiment 2

[0019] Put the Al-Si-Cu alloy ingot into a graphite crucible and overheat it to 745°C to completely melt the aluminum block, then refine and remove slag, and then add a small piece of Al-Sr master alloy (the mass fraction of Sr is 10wt.%), Formulate an aluminum alloy with a mass fraction of Sr in the melt of 0.05wt.%, then heat it up to 765°C with the furnace and keep it warm for 18 minutes, then place the preheated ultrasonic horn probe in the melt, and apply Intermittent ultrasound, the interval between each ultrasound is 2s, the release time of each ultrasound is 2.0s, the ultrasound power is 1.5kw, the ultrasound frequency is 20kHz, the total ultrasound time is 4min, after the ultrasound is finished, it is cooled to 595°C with the furnace and left standing Keep warm for 9 minutes, then apply intermittent ultrasound to the melt again, the interval between each ultrasound is 2s, the release time of each ultrasound is 2.0s, the ultrasonic power is 1.5kw, the ultrasonic frequen...

Embodiment 3

[0021] Put the Al-Si-Cu alloy ingot into a graphite crucible and superheat it to 750 °C to completely melt the aluminum block, then refine and remove slag, and then add a small piece of Al-Sr master alloy (the mass fraction of Sr is 11wt.%), Formulate an aluminum alloy with a mass fraction of Sr in the melt of 0.09wt.%, then heat it up to 770°C with the furnace and keep it warm for 20 minutes, then place the preheated ultrasonic horn probe in the melt, and apply Intermittent ultrasound, the interval between each ultrasound is 2s, the release time of each ultrasound is 2.5s, the ultrasound power is 2.0kw, the ultrasound frequency is 20kHz, the total ultrasound time is 5min, after the ultrasound is finished, it is cooled to 585°C with the furnace and left standing Keep warm for 10 minutes, then apply intermittent ultrasound to the melt again, the interval between each ultrasound is 2s, the release time of each ultrasound is 2.5s, the ultrasonic power is 2.0kw, the ultrasonic freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com