Automatic stamping device for machining aluminum alloy door and window components

A technology for aluminum alloy doors and windows and stamping devices, which is applied in metal processing equipment, perforation tools, forming tools, etc., can solve the problems of aluminum door and window profiles being difficult to wash off, repeatedly handling materials, and low work efficiency, so as to reduce the labor intensity of workers. , Improve work efficiency, the effect of high punching pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

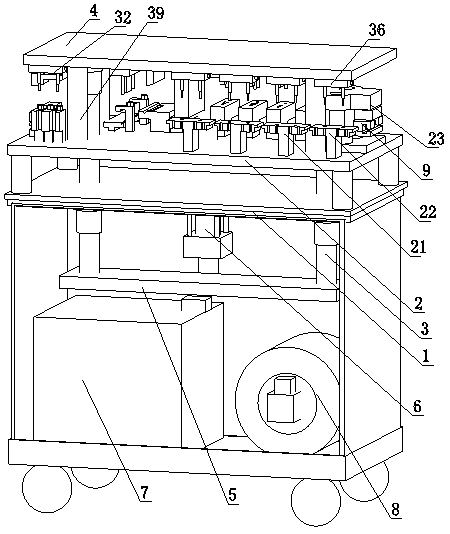

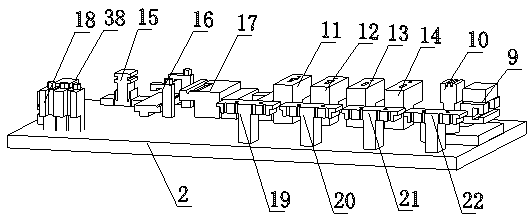

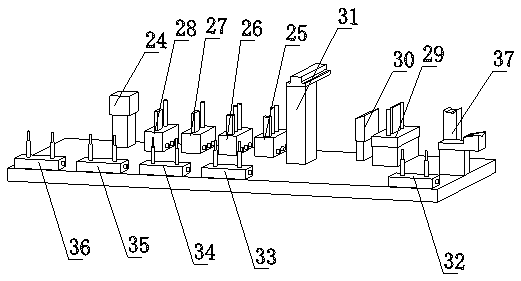

[0017] Such as Figure 1 to Figure 3 The shown automatic stamping device for processing aluminum alloy door and window components includes a frame 1, and the bottom of the frame 1 is provided with four rollers for easy movement. Above the rollers, the bottom of the frame 1 is provided with a lower platform. Template 2 is connected to the top of frame 1, upper template 4 is slidably connected with lower template 2 by two slide bars 3, and upper template 4 is also provided with four guide sleeves 39 connected with it, and lower template 2 is provided with and connected with it and The four guide pillars connected with the guide sleeve on the upper template 4, the connecting rod 5 is connected with the ends of the two slide rods 3 away from the upper template 4; the hydraulic cylinder 6 is located under the lower template 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com