System for purifying volatile organic compounds exhaust gas through plasma synergistic biological technology

A technology of volatile organic compounds and plasma, which is applied in separation methods, dispersed particle separation, air quality improvement, etc., can solve the problems of high investment and operation costs, secondary pollution, and low removal rate of waste gas, so as to improve biodegradability , Reduced footprint, safe and reliable equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

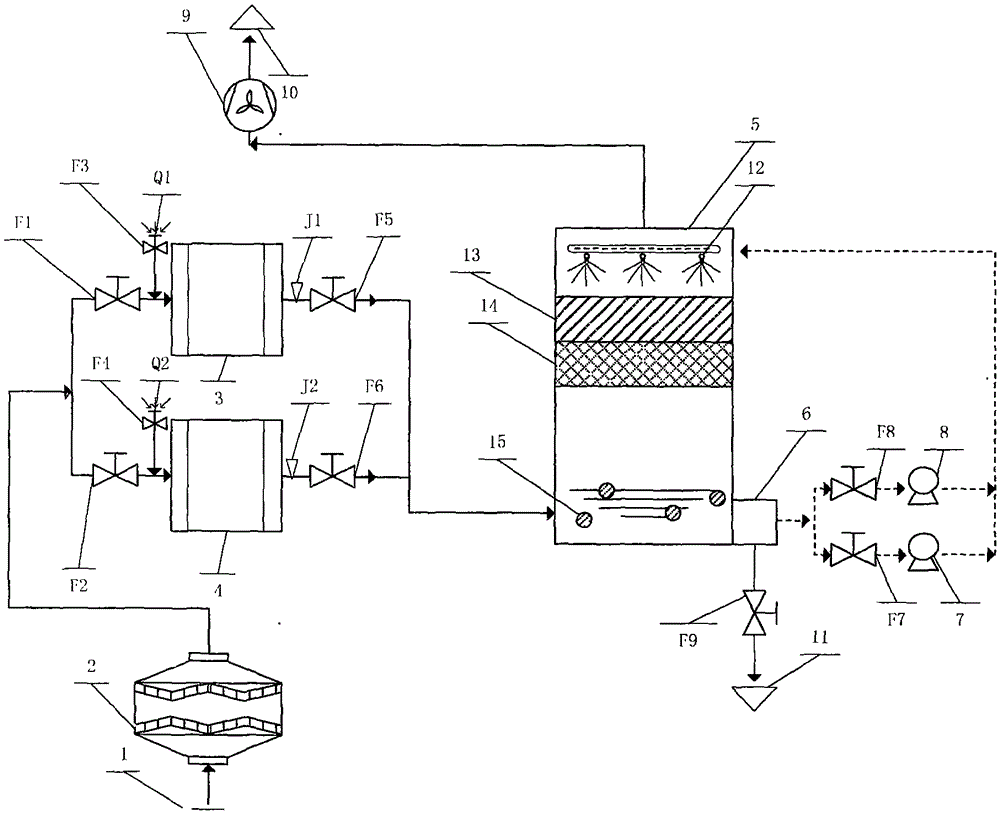

[0033] As shown in the figure, the device for purifying volatile organic compounds (VOCs) in the patent of the present invention mainly includes: air inlet 1, dry filter 2, plasma purification devices 3 and 4, biofilter purification device 5, Circulating water tank 6, circulating water pumps 7 and 8, exhaust fan 9, exhaust cylinder 10, drainage pipe 11, biofilter spray device 12, fixed packing layers 13 (suspended packing) and 14 (volcanic rock), dispersed packing 15, gas Valves F1-F6, water valves F7-F9, air supply ports Q1 and Q2, and detection ports J1 and J2.

[0034] The VOCs that can be purified by the patent of the present invention include benzene and benzene series, alcohols, aldehydes, esters, ketones, etc., especially for the removal of VOCs with large molecules, complex structures, and poor biodegradability. Advantages that cannot be compared with biological methods.

[0035] The air inlet 1 collects VOCs exhaust gas, and after collection, the waste is transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com