Cartilage tissue repair membrane and preparation method thereof

A cartilage tissue and membrane fiber technology, which is applied in the field of cartilage tissue repair membranes and its preparation, can solve the problems of long preparation period, complicated preparation method and high preparation cost, and achieve the effect of low cost, simple preparation method and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

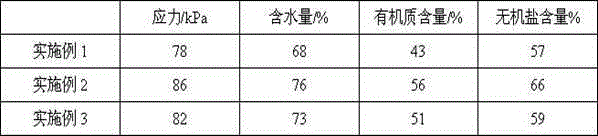

Examples

Embodiment 1

[0023] A cartilage tissue repair film, which is mainly made of the following raw materials in proportion by weight: 25 parts of collagen, 13 parts of aminodextran, 11 parts of hyaluronic acid, 8 parts of chitosan, 4 parts of fibronectin, Keratin 10 parts, membrane fiber 5 parts, sorbitol 14 parts, sodium lauryl sulfate 10 parts, cellulose gum 14 parts, benzyl alcohol 10 parts, double distilled water 35 parts.

[0024] A method for preparing a cartilage tissue repair membrane, comprising the following steps:

[0025] (1) Dissolve sorbitol, hyaluronic acid, sodium lauryl sulfate and benzyl alcohol in double distilled water, stir well and place in a constant temperature water bath at 32°C; add collagen, fibronectin and keratin to it, Stir until completely dissolved;

[0026] (2) Put aminodextran, chitosan, membrane fiber and cellulose gum in a reaction kettle, make a melt at a temperature of 380°C and a pressure of 1.9MPa, and dry and pulverize it to produce Powder, particle si...

Embodiment 2

[0030] A cartilage tissue repair film, mainly made of the following raw materials according to the weight ratio: 42 parts of collagen, 23 parts of aminodextran, 21 parts of hyaluronic acid, 19 parts of chitosan, 13 parts of fibronectin, 28 parts of keratin, 13 parts of membrane fiber, 23 parts of sorbitol, 22 parts of sodium lauryl sulfate, 33 parts of cellulose gum, 21 parts of benzyl alcohol, 55 parts of double distilled water.

[0031] A method for preparing a cartilage tissue repair membrane, comprising the following steps:

[0032] (1) Dissolve sorbitol, hyaluronic acid, sodium lauryl sulfate and benzyl alcohol in double distilled water, stir well and place in a constant temperature water bath at 36°C; add collagen, fibronectin and keratin to it, Stir until completely dissolved;

[0033] (2) Put aminodextran, chitosan, membrane fiber and cellulose gum in a reaction kettle, make a melt at a temperature of 430°C and a pressure of 3.5MPa, and dry and pulverize it to produce...

Embodiment 3

[0037] A cartilage tissue repair film, which is mainly made of the following raw materials in proportion by weight: 50 parts of collagen, 28 parts of aminodextran, 24 parts of hyaluronic acid, 24 parts of chitosan, 14 parts of fibronectin, Keratin 32 parts, membrane fiber 15 parts, sorbitol 26 parts, sodium lauryl sulfate 25 parts, cellulose gum 36 parts, benzyl alcohol 26 parts, double distilled water 65 parts.

[0038] A method for preparing a cartilage tissue repair membrane, comprising the following steps:

[0039] (1) Dissolve sorbitol, hyaluronic acid, sodium lauryl sulfate and benzyl alcohol in double distilled water, stir well and place in a constant temperature water bath at 37°C; add collagen, fibronectin and keratin to it, Stir until completely dissolved;

[0040] (2) Put aminodextran, chitosan, membrane fiber and cellulose gum in a reaction kettle, make a melt at a temperature of 490°C and a pressure of 3.7MPa, dry and pulverize Powder, particle size is 1300 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com