Orally disintegrating tablet containing polacrilin potassium-fluoxertine hydrochloride compound and preparation method of orally disintegrating tablet

A technology of fluoxetine hydrochloride and polacrilin potassium, applied in the field of orally disintegrating tablets and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

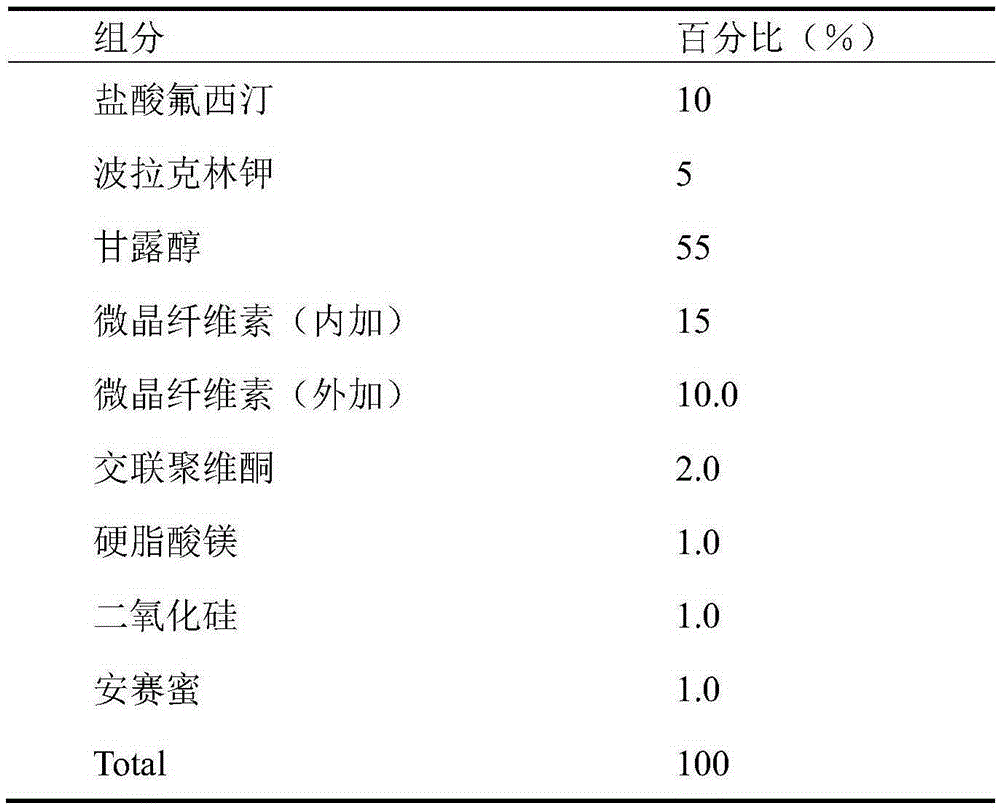

Embodiment 1

[0013] In this embodiment, the ratio of fluoxetine hydrochloride and polacrilin potassium is 1:0.5, the ratio of polacrilin potassium and fluoxetine hydrochloride solid to water is 1:50, the selected organic solvent is ethanol, and the ratio of alcohol to water is 1:5, using the precipitation method and adding organic solvents to prepare the complex.

[0014]

[0015] Preparation process: Add 50g of polacrilin potassium and 100g of fluoxetine hydrochloride into 7.5kg of water and stir for 1 hour to fully disperse and form a complex, add 2000L of ethanol, let stand for 12h, and remove the supernatant , then add 550g mannitol and 150g microcrystalline cellulose to the sediment, use a wet granulator to stir and granulate, granulate with a 24-mesh sieve, dry on a fluidized bed at 50°C for 20min, reduce the water content to below 3%, and granulate Finally, add 100g of microcrystalline cellulose, 20g of crospovidone, 10g of magnesium stearate, 10g of silicon dioxide, and 10g of a...

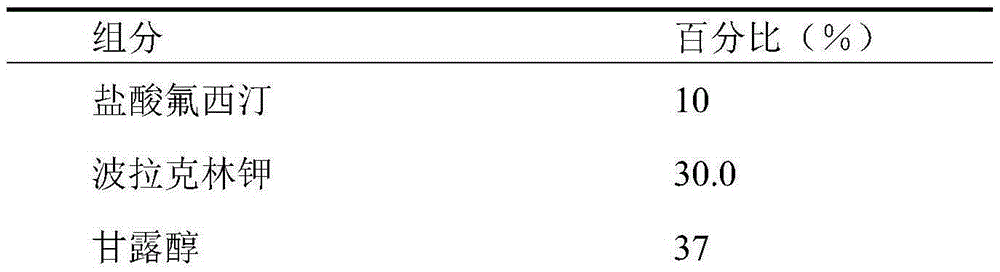

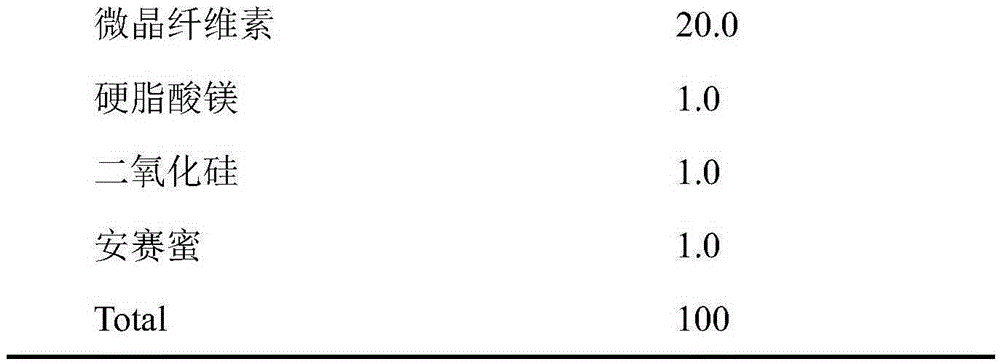

Embodiment 2

[0017] In this example, the ratio of fluoxetine hydrochloride to polacrilin potassium is 1:3, the ratio of polacrilin potassium and fluoxetine hydrochloride solid to water is 1:30, and the complex is prepared by centrifugation.

[0018]

[0019]

[0020] Preparation process: Weigh 100g of fluoxetine hydrochloride and 300g of polacrilin potassium, add them into 12kg of water, stir to make them fully dispersed, and form a complex. After off-line, remove the supernatant, and then add 100g of microcrystalline fiber Su, 370g mannitol, stirred evenly with a wet granulator, granulated with a 24-mesh sieve, spray-dried at 50°C and granulated, then added 100g of microcrystalline cellulose, 10g of magnesium stearate, 10g of silicon dioxide, 10g of ammonium Saimi, mix evenly, according to the content of fluoxetine hydrochloride in the granules, convert the weight of the tablet and press the tablet, the yield can reach more than 90%, the disintegration speed is 15±3s, the taste is sl...

Embodiment 3

[0022] In this embodiment, the ratio of fluoxetine hydrochloride to polacrilin potassium is 1:2, and the ratio of polacrilin potassium and fluoxetine hydrochloride solid to water is 1:60.

[0023]

[0024] Preparation process: Weigh 100g of fluoxetine hydrochloride and 200g of polacrilin potassium, add them into 1.8kg of water, stir to make them fully dispersed, and form a complex, and then use the spray drying method to make the complex powder from the suspension liquid, Then add 100g of microcrystalline cellulose and 460g of lactose, use a wet granulator to mix evenly, add an appropriate amount of 30% ethanol to stir and granulate, and shake the granulator to pass through a 20-mesh sieve to granulate, dry in an oven at 50°C, and then granulate. Add 100g of microcrystalline cellulose, 20g of low-substituted hydroxypropyl cellulose, 10g of magnesium stearate, and 10g of sucralose, and mix well. According to the content of fluoxetine hydrochloride in the granules, the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com