Aluminum pouch film for secondary battery, packaging material comprising same, secondary battery comprising same, and manufacturing method therefor

A secondary battery and soft coating technology, which is applied in the direction of battery box/case material, electrolyte battery manufacturing, battery, etc., can solve the problems of difficulty in obtaining equivalent to hexavalent chromium, lower processing speed, poor working environment, etc., and achieve realization Environmental friendliness and economic efficiency, delamination prevention, chemical reaction prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1~6

[0040] Examples 1-3 and Comparative Examples 1-6: Manufacture of Aluminum Soft Cover Film

[0041] The aluminum soft coating for secondary batteries according to the present invention will be described in detail through the following examples.

Embodiment 1

[0043] A 40 µm-thick aluminum foil (manufactured by Dong-il Aluminum) was cut into an area of 30 cm x 20 cm, and then washed with water, thereby removing dust on its surface.

[0044] Next, the outer resin layer was stacked on the first surface of the aluminum foil in such a manner that a 4 μm thick polyurethane adhesive resin (manufactured by Hi-Chem) was applied and a 25 μm thick layer was formed on the aluminum layer by dry lamination. Nylon 6 (manufactured by Hyosung) was aged at 40°C for 7 days.

[0045] Next, the inner resin layer was stacked on the second surface of the aluminum foil in such a manner that a 4 μm-thick adhesive was applied, wherein the adhesive included polyurethane (manufactured by Mitsui) mixed in a weight ratio of 70:30 as the main Components and one chain of polyols with SiO 2 modified monomer (manufactured by Rhodia); and polypropylene (manufactured by Okamoto) was formed to a thickness of 40 μm on the aluminum layer by dry lamination, followed b...

Embodiment 2

[0047] A 40 µm-thick aluminum foil (manufactured by Dong-il Aluminum) was cut into an area of 30 cm x 20 cm, and then washed with water, thereby removing dust on its surface.

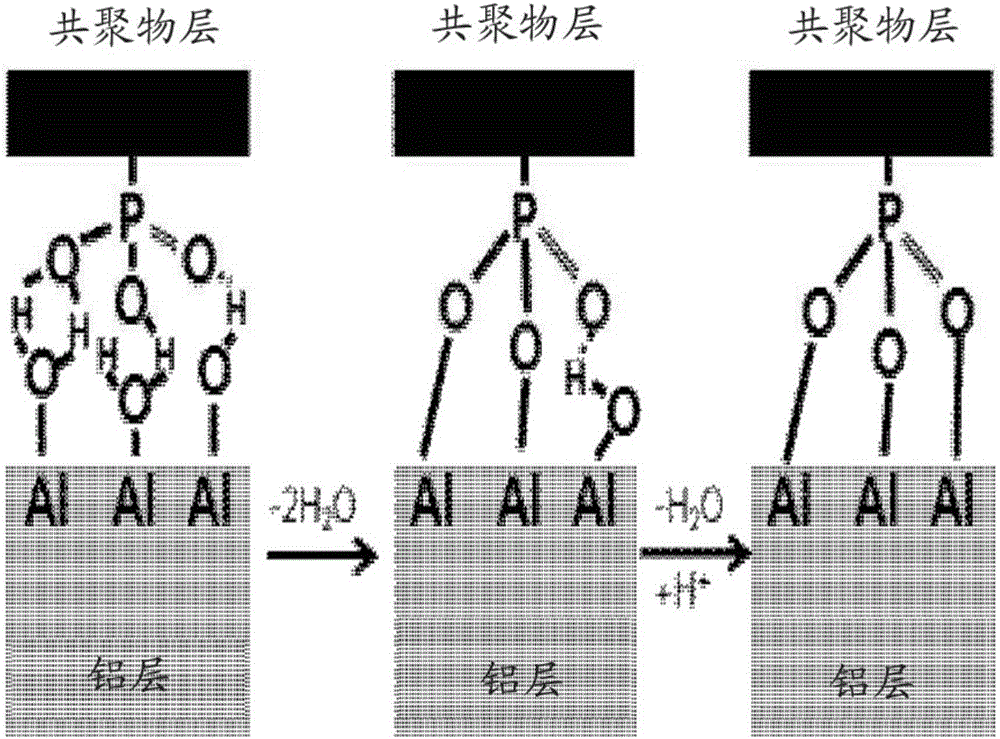

[0048] Next, the copolymer layer was stacked on the second surface of the aluminum foil by applying a 5 μm thick mixture comprising VPA (vinylphosphonic acid) (manufactured by Rhodia) and AA (acrylic acid) at a thickness of 5:1, and then Heat treatment at 120°C for 3 days.

[0049] Next, the outer resin layer was stacked on the first surface of the aluminum foil in such a manner that a 4 μm thick polyurethane adhesive resin (manufactured by Hi-Chem) was applied and a 25 μm thick layer was formed on the aluminum layer by dry lamination. Nylon 6 (manufactured by Hyosung) was aged at 40°C for 7 days.

[0050] Next, the inner resin layer was stacked on the second surface of the aluminum foil having the copolymer layer in such a manner that a 4 μm thick polyurethane adhesive (manufactured by Mitsui) was a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com