Optical semiconductor integrated element and method for manufacturing same

An optical semiconductor and integrated component technology, which is applied to optical components, semiconductor lasers, semiconductor laser devices, etc., can solve the problems of increased optical transmission loss, peeling of mask 68, and reduced pattern accuracy, so as to reduce transmission loss and eliminate manufacturing. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

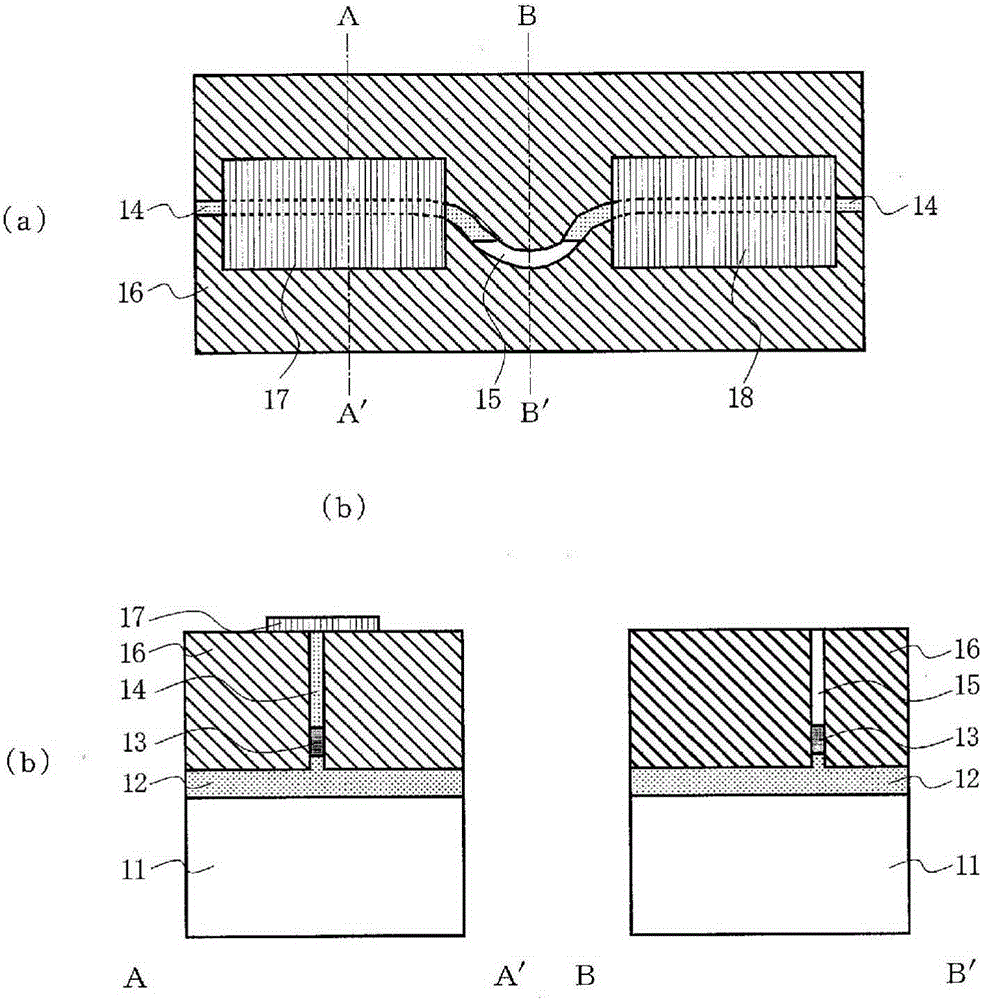

[0054]Next, refer to Figure 3 ~ Figure 6 , the capacity-loaded MZ modulator according to Embodiment 1 of the present invention will be described. image 3 is an explanatory diagram of a capacity loading type MZ modulator according to Embodiment 1 of the present invention, image 3 (a) is a top view, image 3 (b) for along image 3 A cross-sectional view of the dotted line connecting A-A' in (a), image 3 (c) for along image 3 Cross-sectional view of the dotted line connecting BB' in (a). This capacity-loaded MZ modulator includes an input waveguide 32 , a 1×2 MMI (multimode interference) waveguide 33 , two zigzag-shaped modulation waveguides, a 2×1 MMI waveguide 34 , and an output waveguide 35 .

[0055] The two modulation waveguides have a structure in which waveguide portions where electrodes 30 and 31 are formed and waveguide portions where no electrodes are formed are alternately arranged. Such as image 3 As shown in (b), the waveguide connected to the electrodes...

Embodiment 2

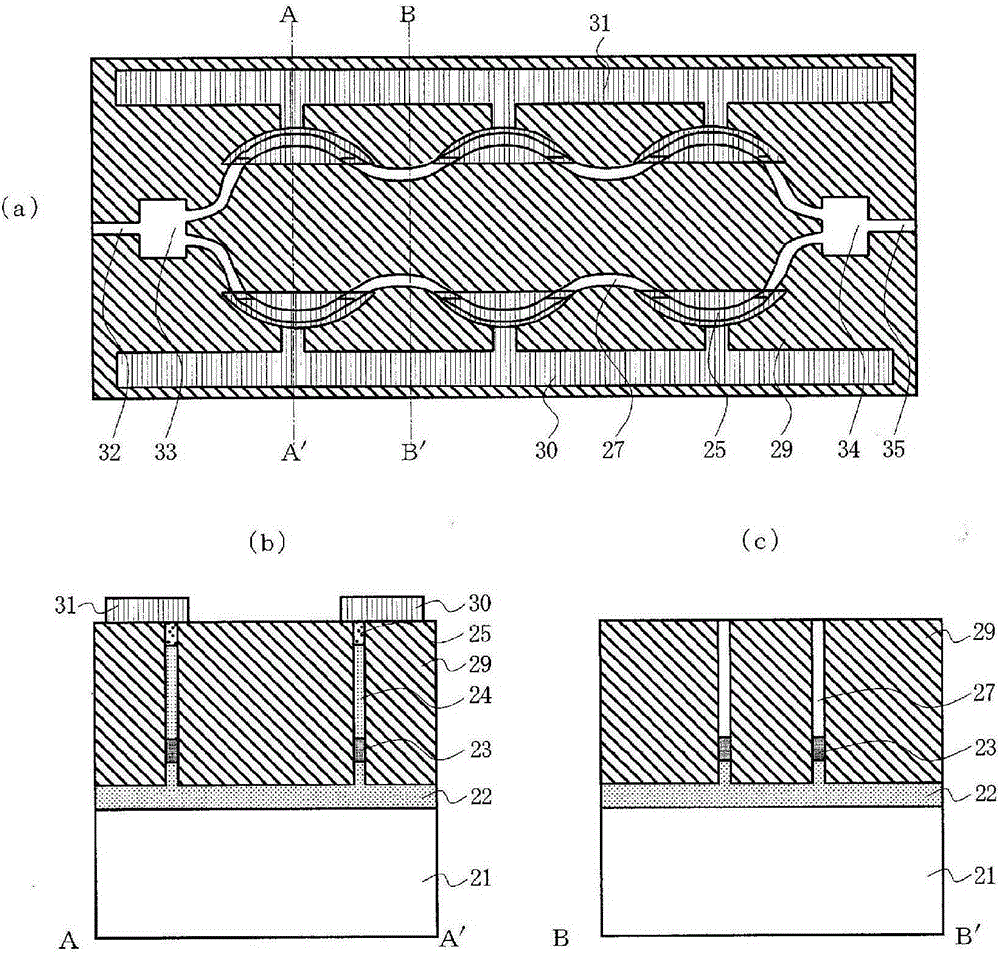

[0071] Next, refer to Figure 8 ~ Figure 11 , the optical semiconductor integrated element of Embodiment 2 of the present invention will be described, but here, it will be described as an optical semiconductor integrated element integrating a DFB (distributed feedback type) semiconductor laser and a semiconductor optical amplifier (SOA). Figure 8 It is an explanatory drawing of the optical semiconductor integrated element of Example 2 of the present invention, Figure 8 (a) is a top view, Figure 8 (b) for along Figure 8 A cross-sectional view of the dotted line connecting A-A' in (a), Figure 8 (c) for along Figure 8 Cross-sectional view of the dotted line connecting BB' in (a).

[0072] Such as Figure 8 As shown in (a), the waveguide constituting the DFB semiconductor laser and the waveguide constituting the semiconductor optical amplifier are arranged at the same position in a direction perpendicular to the direction in which the waveguides extend. In the separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com