Method for regenerating glass polishing solution and glass polishing apparatus

A grinding device and technology for grinding liquid, applied in the regeneration method of glass grinding liquid, regeneration device, glass substrate manufacturing device, and the field of glass substrates used in the field of glass substrates, can solve the problems of time and economy that cannot be said to be optimal, and it is difficult to achieve uniform thickness. Problems such as difficulty in thickness control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

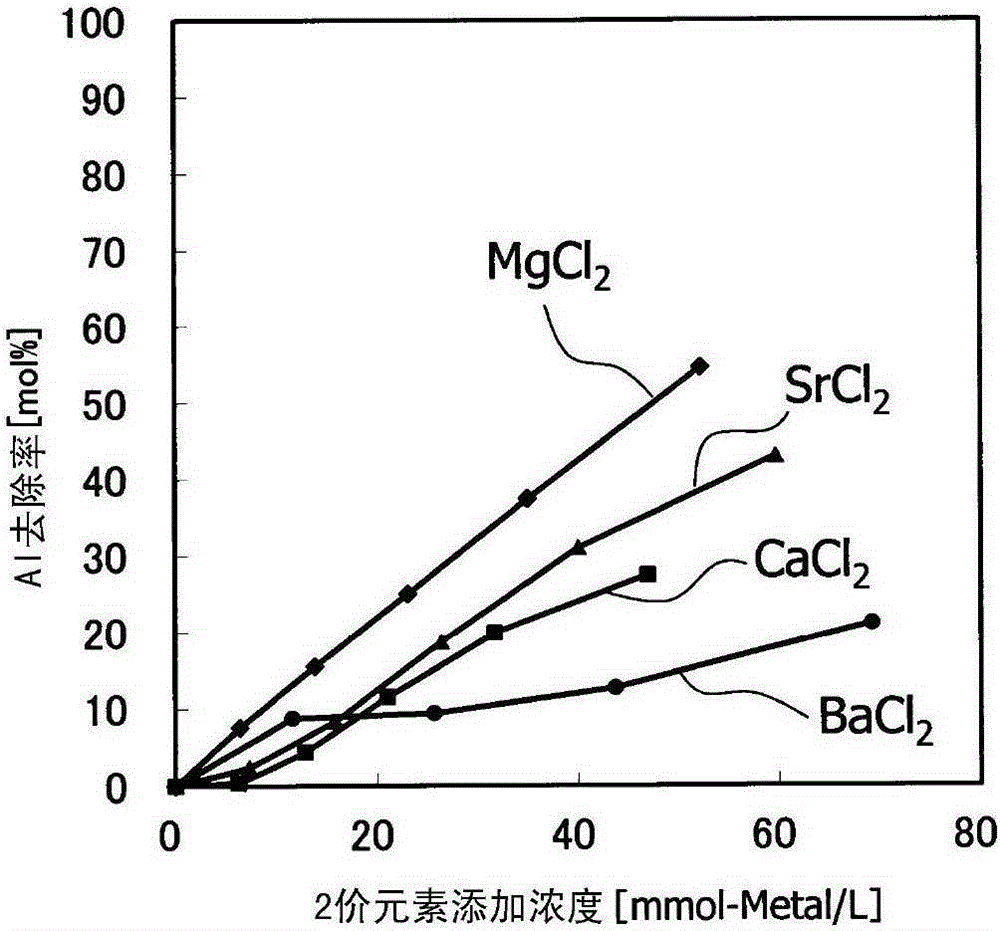

[0165] In the glass grinding method and device of the present invention, the grinding object is aluminoborosilicate glass. More specifically, for SiO 2 as the main body, containing Al 2 o 3 , B 2 o 3 , BaO, CaO, MgO, Na 2 O, SrO, strengthened glass with high tensile strength and high softening point. Glass containing aluminum may also be used. Hereinafter, it is also referred to as "Al-containing glass". The polishing solution is mainly composed of hydrofluoric acid, and contains inorganic acids such as hydrochloric acid, nitric acid, and sulfuric acid. Moreover, additives, such as a surfactant, an antifoaming agent, and a chelating agent, may be contained.

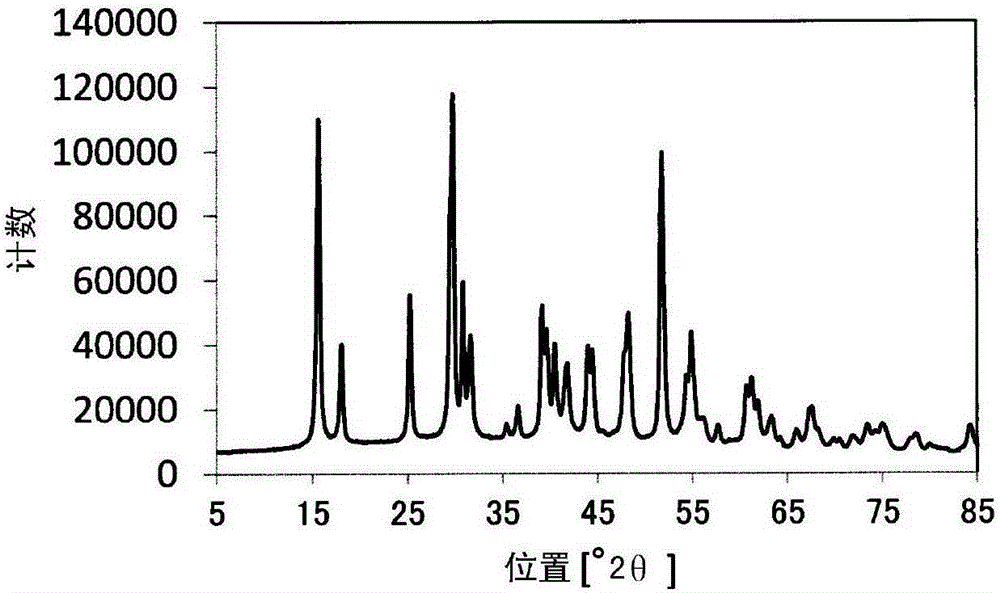

[0166] Sludge generated when aluminoborosilicate glass is polished is a substance precipitated from the polishing solution in a complex formed by bonding elements in the aluminoborosilicate glass to fluorine derived from hydrofluoric acid in the polishing solution . The inventors of the present applica...

Embodiment approach 2

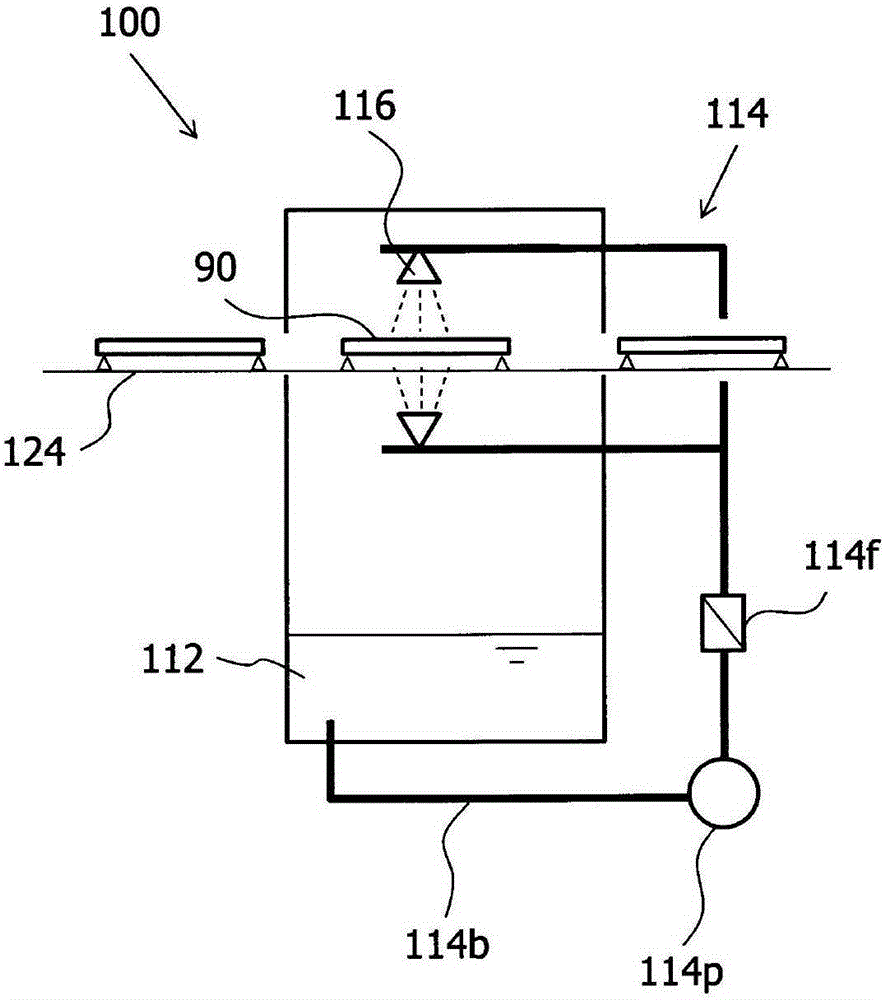

[0263] In the glass polishing device 1 described in Embodiment 1, an Al-F complex removal device 21 is constituted by a reaction tank 20 and a metal salt addition part 22 for removing Al. This is considered to be because not even a small amount of sludge remains in the storage unit 12 in which the polishing liquid circulates is effective in reducing defective products. That is, it is considered that when sludge remains in the polishing liquid, the sludge remains on the glass surface during polishing, which forms a sludge trace and causes quality deterioration.

[0264] However, the polishing liquid is sprayed to the surface of the glass to be polished so as to advance uniformly, or the glass is immersed in the polishing liquid. Furthermore, washing with water was also performed after grinding|polishing. Therefore, it is considered that even if mud is mixed in the polishing liquid, it is difficult to remain as mud marks only after reaching the glass surface. This is becau...

Embodiment

[0392] Various tests were conducted in order to confirm the effectiveness of the present invention.

[0393] "Confirmation of the aggregation of sludge by adding a coagulant to a slurry containing sludge and the formation of aggregates and their sedimentation"

[0394] In order to confirm the aggregation of the sludge by the addition of the coagulant, the formation of aggregates, and its sedimentation, add 1 mL of Aqueous solutions containing the following coagulants at a concentration of 0.1% by weight, respectively. It should be noted that the concentration of the coagulant in the grinding liquid after adding the coagulant is 20 mg / L (or 0.13 mg / 100 mg·DS).

[0395] Coagulant 1: Polyacrylamide-based polymer (Accofloc N-100S manufactured by MTAQUAPOLYMER, Inc.: nonionic polymer, acrylamide polymerized unit: 100%, pH of aqueous solution: 5 to 7, molecular weight: 13 million, 0.1% by weight solution Viscosity: 20mPa / s(25℃))

[0396] Coagulant 2: Sodium polyacrylate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com