Mounting structure of oxygen sensor of motorcycle

An oxygen sensor and installation structure technology, which is applied in the field of oxygen sensor installation structure, can solve the problems of collision or damage, low cost, high cost, etc., and achieves the effect of remarkable effect, reduced production cost, and large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

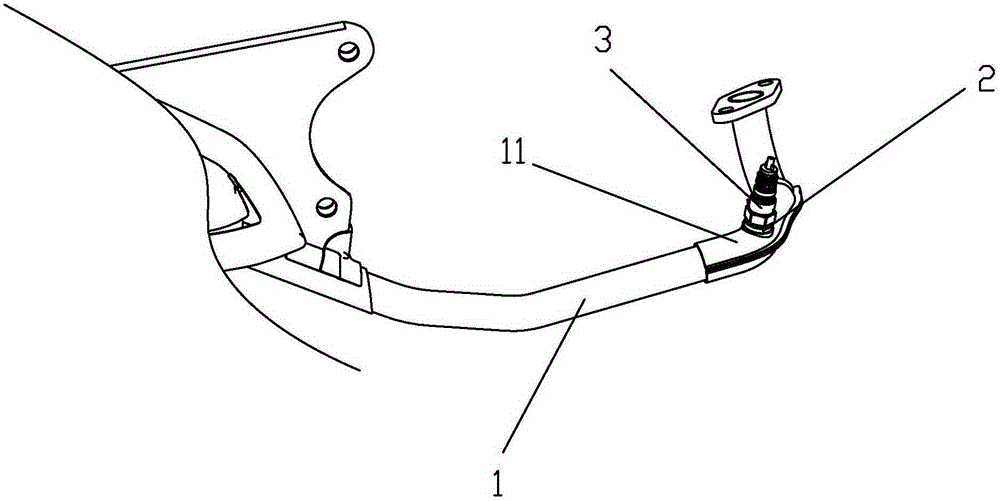

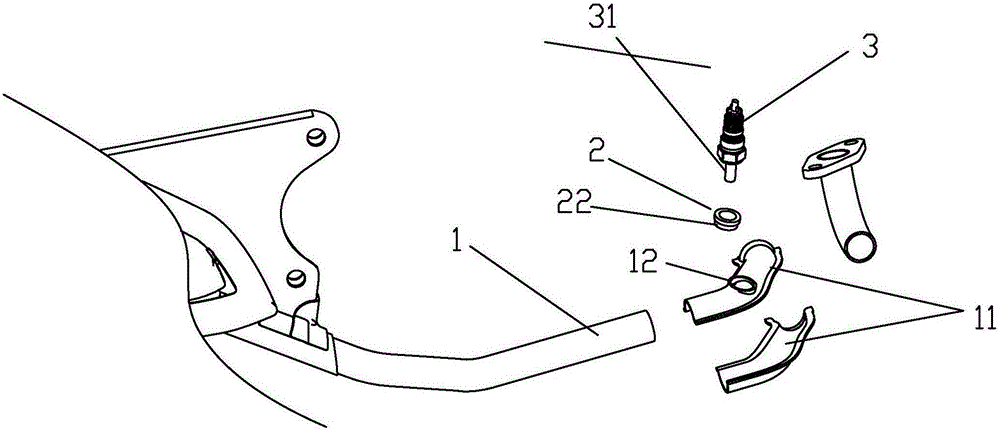

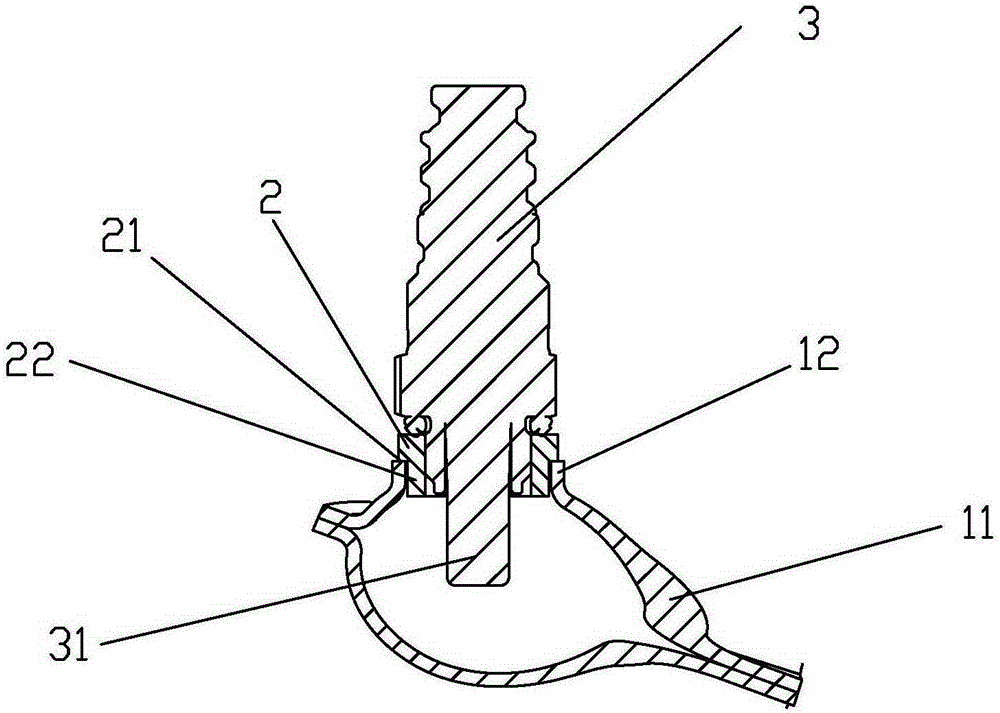

[0021] refer to Figure 1 to Figure 3 , a motorcycle oxygen sensor installation structure, comprising a motorcycle exhaust pipe 1 connected to the engine cylinder head, an oxygen sensor 3 is fixedly installed on the outer surface of the exhaust pipe 1, and the measuring head 31 of the oxygen sensor 3 passes through the The mounting seat 2 and the surface of the exhaust pipe 1 extend into the exhaust pipe 1. The exhaust pipe 1 of the present invention adopts a segmented structure design, and then each segment is combined and fixed as a whole, and is preferably fixedly connected by welding. The turning of the exhaust pipe near the end of the cylinder head is designed as an independently formed special-shaped pipe, and the oxygen sensor 3 is installed on the special-shaped pipe 11. The ideal position and shape facilitate the arrangement of the oxygen sensor, and prevent the circular pipes in the prior art from being difficult to arrange in the most suitable spatial position due ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com