Beta-cyclodextrin-based nanometer fiber film, preparation method thereof, and application of beta-cyclodextrin-based nanometer fiber film to dye adsorption and separation

A nanofiber membrane, cyclodextrin technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve problems such as limited use capacity, achieve good adsorption capacity, good film-forming properties, and reduce economic losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Dissolve β-cyclodextrin in the solvent N,N-dimethylformamide and stir until completely dissolved, wherein the mass fraction of β-cyclodextrin is 25wt%; after the cyclodextrin is completely dissolved, add citric acid, The polyacrylic acid is stirred until it is completely dissolved, wherein the mass of citric acid and polyacrylic acid accounts for 35% and 20% of the mass of β-cyclodextrin respectively; after the solution is completely dissolved, a spinning solution is obtained, and the spinning solution is electrospun; The obtained spun nanofibers were placed in a digital display electric heating constant temperature drying box for high-temperature in-situ thermal cross-linking. The cross-linking temperature was 200°C and the cross-linking time was 2 hours. The β-cyclodextrin-based electrospun nanofibers were obtained. Dye adsorption, separation membrane. The obtained β-cyclodextrin-based electrospun nanofiber membrane has a maximum adsorption capacity of 850 mg / g for th...

Embodiment 2

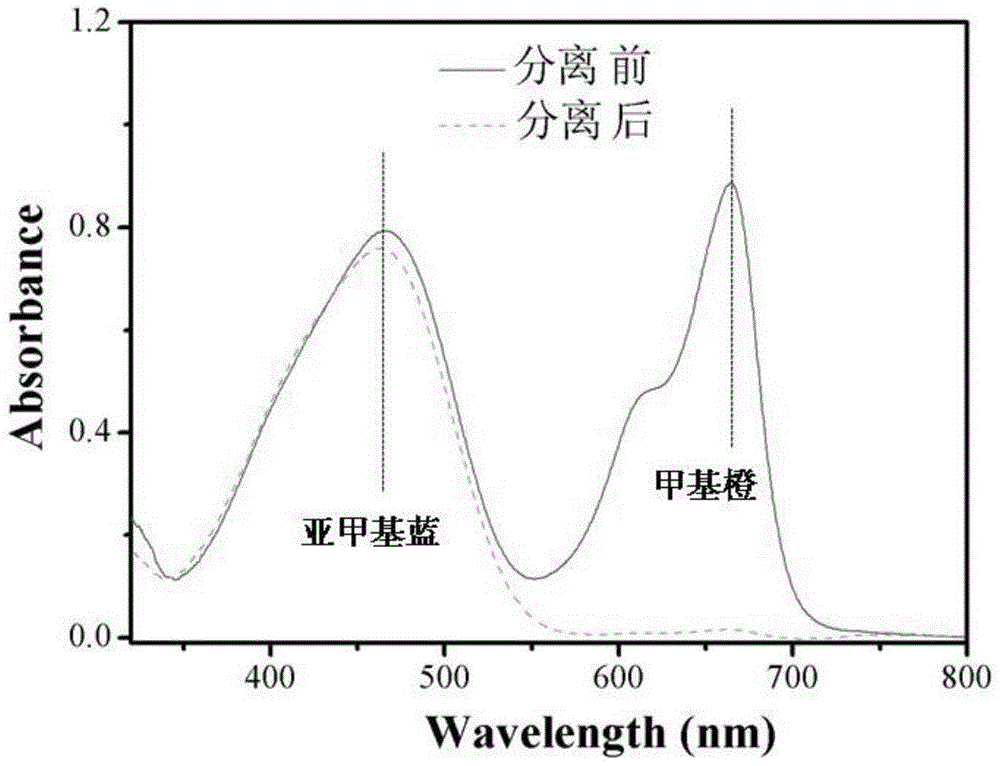

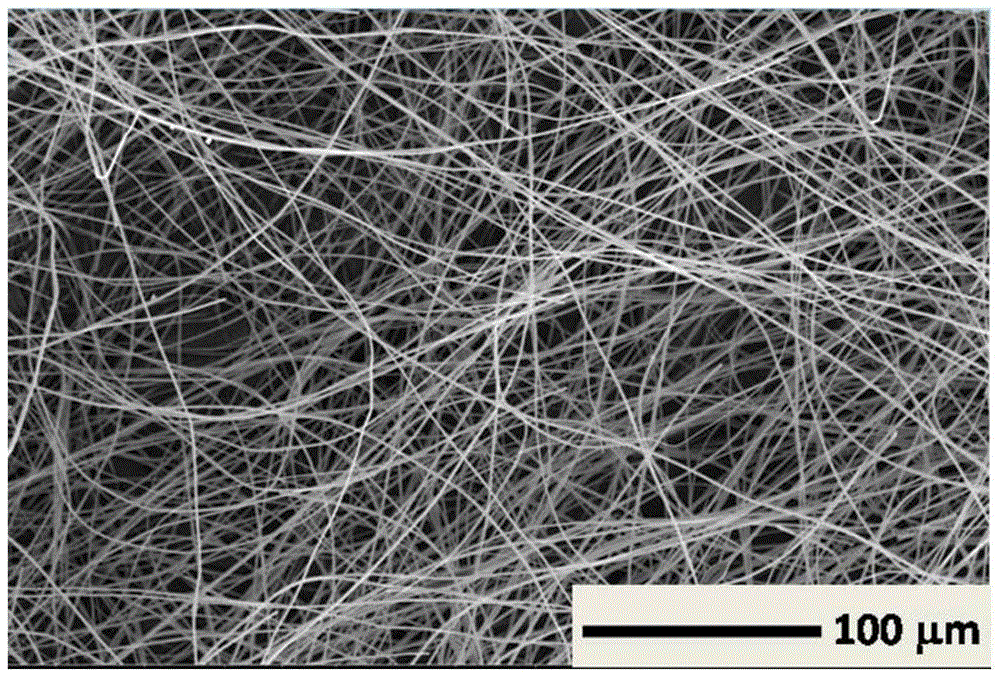

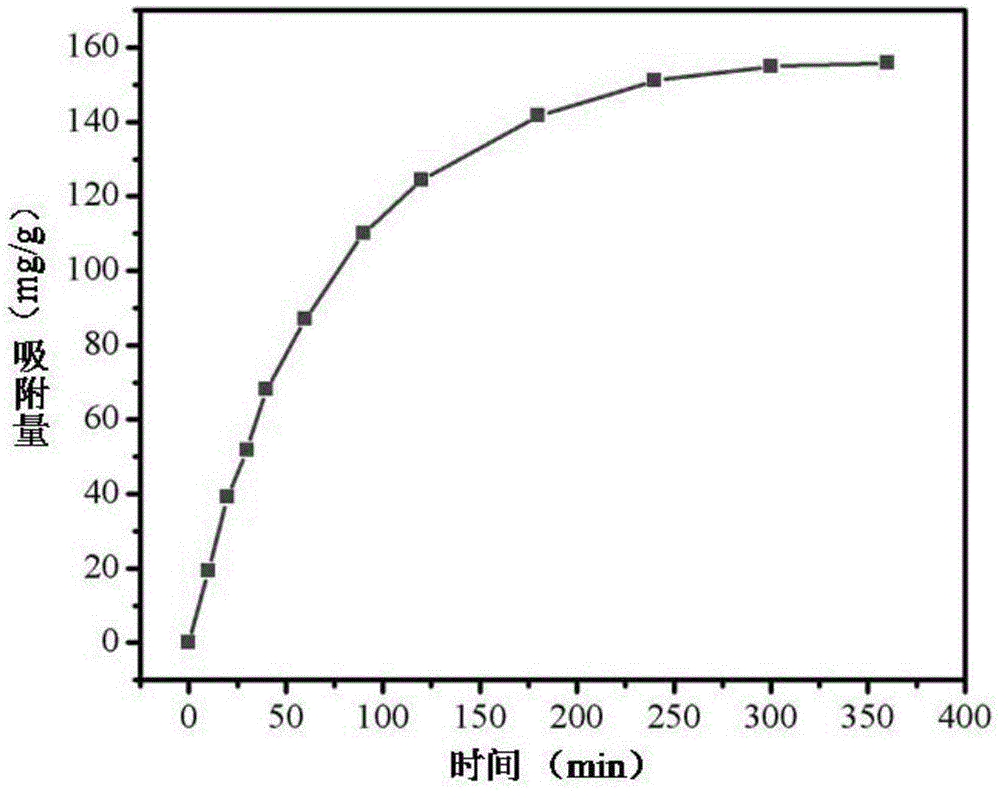

[0030] Dissolve β-cyclodextrin in the solvent N,N-dimethylformamide and stir until completely dissolved, wherein the mass fraction of β-cyclodextrin is 15wt%; after the cyclodextrin is completely dissolved, add citric acid, The polyacrylic acid is stirred until it is completely dissolved, wherein the mass of citric acid and polyacrylic acid account for 20% and 10% of the mass of β-cyclodextrin respectively; after the solution is completely dissolved, a spinning solution is obtained, and the spinning solution is electrospun; The obtained spun nanofibers were placed in a digital display electric heating constant temperature drying box for high-temperature in-situ thermal cross-linking. The cross-linking temperature was 220°C and the cross-linking time was 1 hour. The β-cyclodextrin-based electrospun nanofiber dye was obtained. Adsorption, separation membrane (such as figure 2 , scanning electron micrograph). The obtained β-cyclodextrin-based electrospun nanofibrous membrane ha...

Embodiment 3

[0032]Dissolve β-cyclodextrin in the solvent N,N-dimethylformamide and stir until completely dissolved, wherein the mass fraction of β-cyclodextrin is 20wt%; after the cyclodextrin is completely dissolved, add citric acid, The polyacrylic acid is stirred until it is completely dissolved, wherein the mass of citric acid and polyacrylic acid accounts for 15% and 30% of the mass of β-cyclodextrin respectively; after the solution is completely dissolved, a spinning solution is obtained, and the spinning solution is electrospun; The obtained spun nanofibers were placed in a digital display electric heating constant temperature drying box for high-temperature in-situ thermal crosslinking. The crosslinking temperature was 170°C and the crosslinking time was 3 hours, and the β-cyclodextrin-based electrospun nanofibers were obtained. Dye adsorption, separation membrane. Adsorption of the obtained β-cyclodextrin-based electrospun nanofibrous membrane for the cationic dye basic fuchsin (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com