Method for promoting fermentation production of lactohacillin by preprocessing waste distiller's grains

A technology of rice wine waste and pretreatment, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of rice wine waste not being effectively used, environmental pollution, resource waste, etc., and achieve the solution of by-products Large output, increase output and potency, solve the effect of low utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Production of Lactic Acid Bacteria Preparations by Fermentation of Ordinary Rice Wine Discarded Grains

[0019] 1) Preparation of expansion culture medium: collect 1 kg of fresh yellow rice wine and throw away grains, add 1 kg of water, mix well, add yeast extract 0.3-0.8%; sucrose 1-5%; glucose 1-5%; dipotassium hydrogen phosphate (KH 2 PO 4 ) 0.3-0.5%; and adjust the pH to 5.5-6.5 with 1% HCl or 1% NaOH, and sterilize at 121° C. for 20 minutes.

[0020] 2) Activation of test tube parent species: inoculate Streptococcus lactis into a test tube containing 10 mL of expansion medium, culture at 30°C for 24 hours, and ensure the purity through microscope inspection and slant coating.

[0021] 3) Erlenmeyer flask expansion: according to the inoculum amount of 5%, the test tube seed was inserted into a 150mL Erlenmeyer flask containing 100mL expansion medium, and cultured at 30°C for 24h. According to the inoculum amount of 5%, 90 mL strains in a 150 mL Erlenmeyer flask we...

Embodiment 2

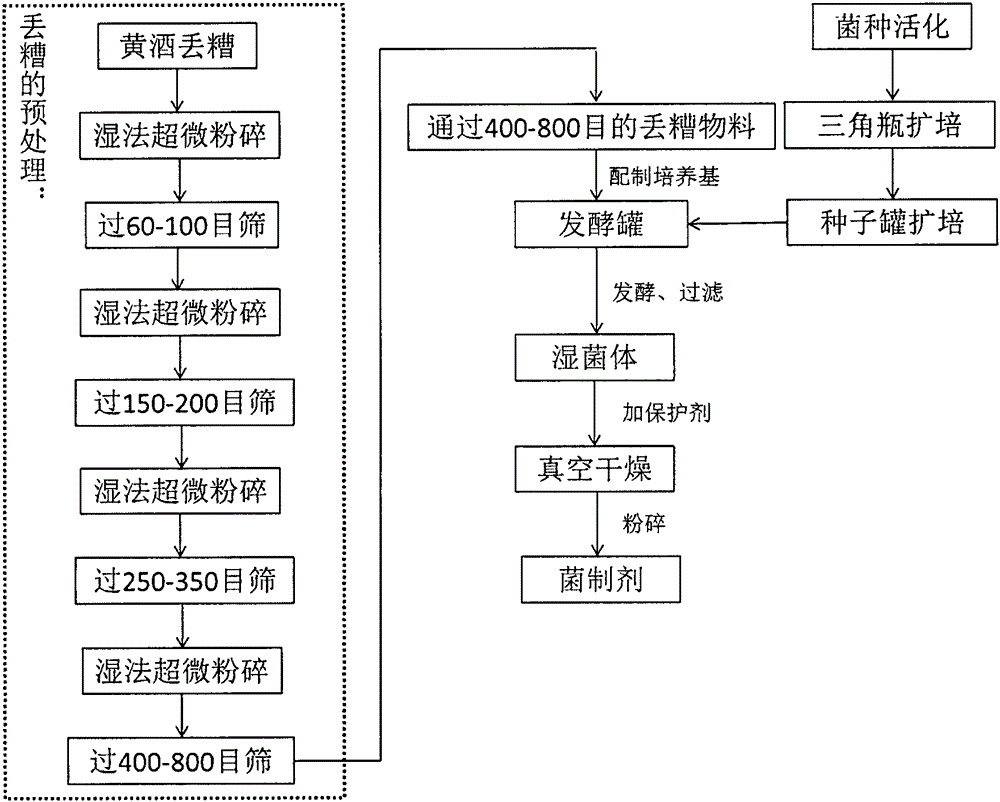

[0029] Combined ultrafine pulverization technology and step-by-step sieving technology to pretreat yellow rice wine grains

[0030] 1) Use wet ultrafine pulverization technology to pretreat yellow rice wine grains: collect 1 kg of fresh yellow rice wine grains, add 1 kg of water, stir evenly with a mechanical stirring shaft, and pass through a wet ultrafine pulverizer (Wuxi Hepu Light Industry Equipment Technology Co., Ltd. produced HOP type cutting wet ultrafine pulverizer) for pulverization, and the pulverization time was 3 minutes.

[0031] 2) Pretreatment of rice wine discarded grains using step-by-step sieving technology: pass the discarded grains material after the first wet superfine grinding through a 100-mesh sieve, and return the material that passed the 100-mesh sieve to the pulverizer for the second wet grinding process. The pulverized material is then passed through a 150-mesh sieve, and the material that passes through the 150-mesh sieve is subjected to the third...

Embodiment 3

[0033] Step-by-step expansion culture of fermentation strains

[0034] 1) Preparation of expansion culture medium: After wet superfine grinding and step-by-step sieving, add yeast extract 0.3-0.8%; sucrose 1-5%; glucose 1-5% ; Dipotassium hydrogen phosphate (KH 2 PO 4) 0.3-0.5%; and adjust the pH to 5.5-6.5 with 1% HCl or 1% NaOH, and sterilize at 121° C. for 20 minutes.

[0035] 2) Activation of test tube parent species: inoculate Streptococcus lactis into a test tube containing 10 mL of expansion medium, culture at 30°C for 24 hours, and ensure the purity through microscope inspection and slant coating.

[0036] 3) Erlenmeyer flask expansion: according to the inoculum amount of 5%, the test tube seed was inserted into a 150mL Erlenmeyer flask containing 100mL expansion medium, and cultured at 30°C for 24h. According to the inoculum amount of 5%, 90 mL strains in a 150 mL Erlenmeyer flask were inserted into a 5000 mL volume Erlenmeyer flask containing 3000 mL expansion med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com