9-acetyl anthracene eutectic material with adjustable up-conversion luminescence and preparation method thereof

A eutectic material, acetyl anthracene technology, applied in the field of fluorescent materials and preparation based on 9-acetyl anthracene eutectic structure, can solve the problems of spatial structure complexity, easy occurrence of photochemical reactions, unpredictability of solid-state emission color, etc. , to achieve the effect of broadening the application space and preparation range, and improving the optical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Weigh 0.044g of 9-acetyl anthracene and dissolve it in 10mL of acetone, fully dissolve to obtain solution A;

[0022] 2. Weigh 0.0356g of 1,2,4,5-tetracyanobenzene and dissolve it in 10mL of methanol. After the dissolution is complete, solution B is obtained;

[0023] 3. The solutions A and B were evenly mixed under ultrasonic conditions, and left to stand in the dark, and crystals formed after one week.

[0024] To characterize the product:

[0025] According to single crystal XRD analysis, 9-acetylanthracene and 1,2,4,5-tetracyanobenzene form co-crystal products through charge transfer force;

[0026] It can be seen from the fluorescence spectrum that the luminescence peak of the eutectic is obviously red-shifted compared with that of 9-acetylanthracene.

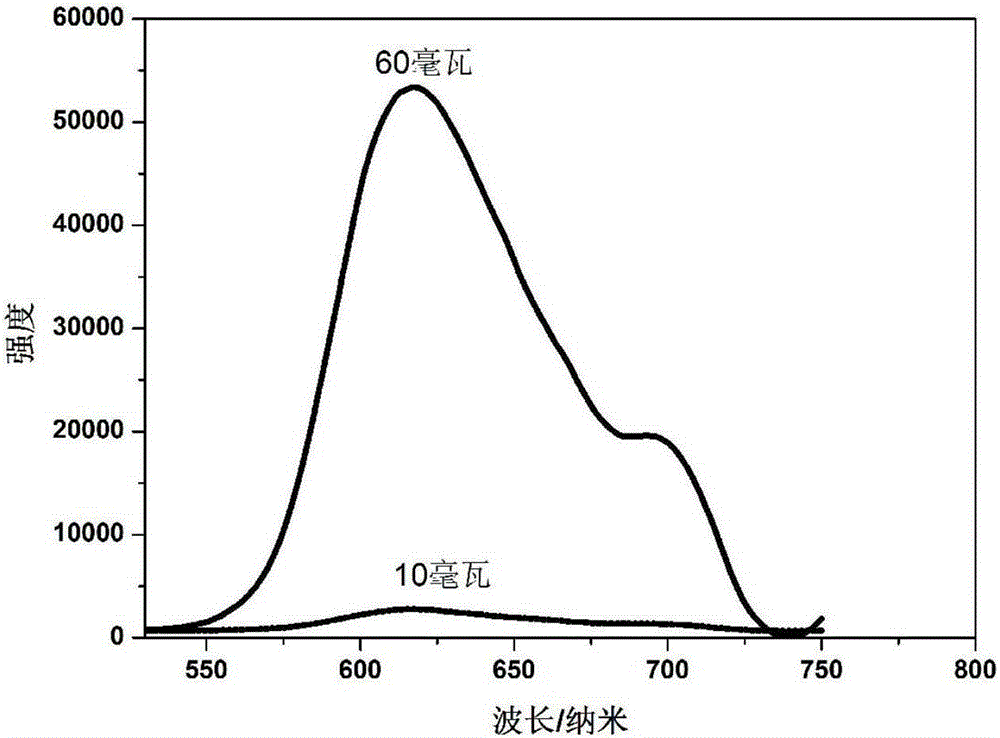

[0027] Under 800nm laser excitation, there is an obvious red light up-conversion signal, such as figure 1 shown.

Embodiment 2

[0029] 1. Weigh 0.044g of 9-acetyl anthracene, 0.0546g of 4-bromo-2,3,5,6-tetrafluorobenzoic acid;

[0030] 2. Mix the two evenly and put them into a ball mill, add 0.1mL of acetone, and grind at 15r / s for 30min;

[0031] 3. Take the ground powder and dissolve it in 20mL of acetone, place it under dark conditions, and wait for the solvent to evaporate completely to obtain the eutectic product.

[0032] Characterize the product:

[0033] From the ground powder PXRD, it can be seen that new substances are produced; from the single crystal XRD analysis, it can be seen that the eutectic product is formed through hydrogen bond interaction;

[0034] It can be seen from the fluorescence analysis that the quantum yield and lifetime of this compound are improved compared with 9-acetylanthracene, and the emission peak position is blue-shifted from 476nm to 450nm;

[0035] Under 800nm laser excitation, blue light up-conversion signals appear, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com