Preparing method for thermosensitive magnetic composite microspheres

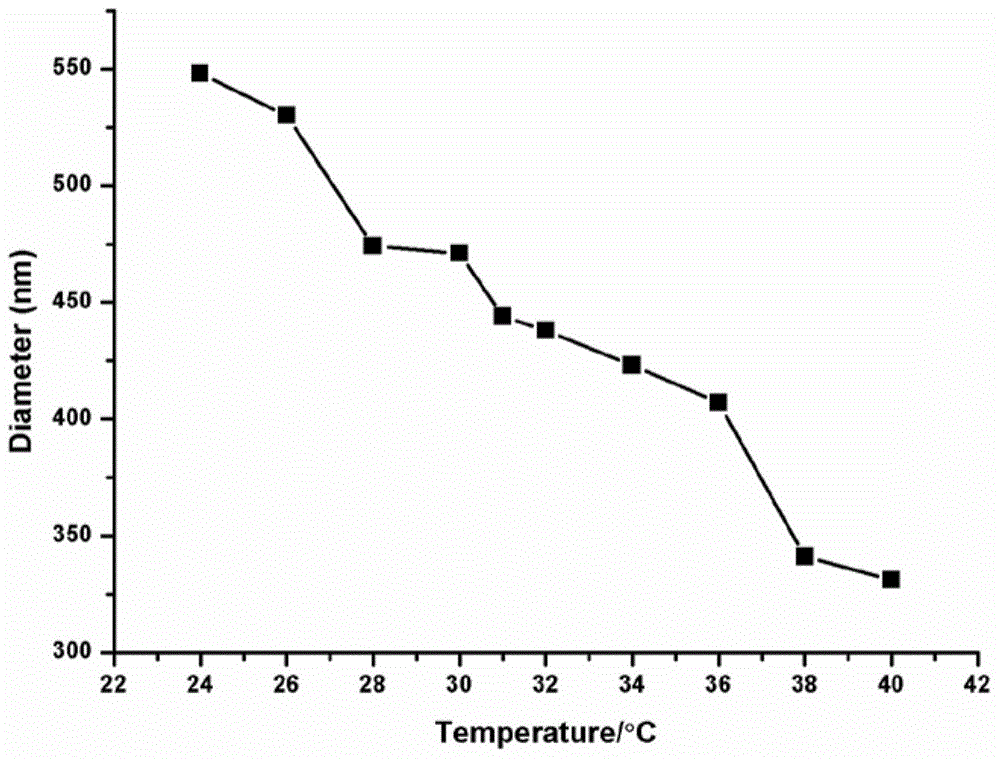

A technology of magnetic composite microspheres and magnetic microspheres, which is applied in the preparation of microspheres, the magnetism of organic materials/organic magnetic materials, and microcapsule preparations, and can solve the problem that the magnetic response performance of composite microspheres is not obvious and the magnetic response performance is not sensitive enough , Low monomer conversion rate and other issues, to achieve good magnetic response, good temperature sensitivity, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: as figure 1 , magnetic Fe 3 o 4 Preparation of microspheres: In a 500ml beaker, add 3.2436g FeCl 3 .6H 2 O, 2.164g urea, 7.056g trisodium citrate, 1.80g PAM (polyacrylamide) and 240ml deionized water, after mixing evenly, pour into four 80ml polytetrafluoroethylene reactors respectively, and react at 200°C for 12h. The obtained product was subjected to magnetic separation, the supernatant liquid was poured off, and magnetic separation was carried out after ultrasonic dispersion with ethanol and deionized water respectively, and repeated washing in this way, and dried at 80°C to obtain nano-core-shell structure Fe 3 o 4 magnetic microspheres.

[0033] Fe 3 o 4 -NH 2 Preparation of microspheres: In a 250ml three-neck flask, add 1.5g nano-core-shell structure Fe 3 o 4 Sonicate the magnetic microspheres and 100ml deionized water for 15min, adjust the pH of the solution to 10.20 with a concentration c=0.008M NaOH solution, activate at 55°C for 2.5h un...

Embodiment 2

[0044] Example 2: Fe 3 o 4 -NH 2 Preparation of microspheres: in a 250ml three-neck flask, add 0.4g of activated Fe in Example 1 3 o 4 Magnetic microspheres, the volume of ethanol and deionized water are 40ml / 40ml, ultrasonically dispersed for 15min, adjust the pH of the solution to 4.0 with glacial acetic acid, add 0.202ml of silane coupling agent KH-550, react at 55°C for 3h, wash with ethanol and deionized Washed several times with ion water and dried at 80°C to obtain Fe 3 o 4 -NH 2 The surface amino content of the microspheres measured by potentiometric titration is 497.05 μmol / g.

[0045] Fe 3 o 4 -NHCO-CH=CH 2 Preparation of microspheres: In a 250ml three-necked flask, 7ml of acrylic acid, 120mgEDC and 250mgNHS were dissolved in 30ml of deionized water, mechanically stirred at 3.4°C for 30min, and 0.75g of the above Fe 3 o 4 -NH 2 Disperse the microspheres in 150ml deionized water, ultrasonically disperse for 15min, add them to the flask, react for 1h, wash ...

Embodiment 3

[0048] Example 3: Fe 3 o 4 -NH 2 Preparation of microspheres: in a 250ml three-neck flask, add 0.4g of activated Fe in Example 1 3 o 4 The volume of microspheres, ethanol and deionized water are 55ml / 45ml respectively, ultrasonically disperse for 15min, adjust the pH of the solution to 4.0 with glacial acetic acid, add 0.606ml of silane coupling agent KH-550, react at 55°C for 3h, wash with ethanol and deionized Washed with water several times, dried at 80°C to obtain Fe 3 o 4 -NH 2 The surface amino content of the microspheres was measured by potentiometric titration to be 463.22 μmol / g.

[0049] Fe 3 o 4 -NHCO-CH=CH 2 Preparation of microspheres: In a 500ml three-necked flask, 15ml of acrylic acid, 300mgEDC and 500mgNHS were dissolved in 40ml of deionized water, mechanically stirred at 3.2°C for 30min, and 1.0g of the above Fe 3 o 4 -NH 2 Disperse the microspheres in 200ml deionized water, ultrasonically disperse for 15min, put them into the flask, react for 1h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Magnetic saturation | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com