Production method for feed grade particulate calcium dihydrogen phosphate

A technology of calcium dihydrogen phosphate and its production method, which is applied in the fields of chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., and can solve the problems of impossibility of increasing device capacity, impossibility of long-term production, high production cost, etc., and meet the requirements of raw material grade Low cost, low production cost, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

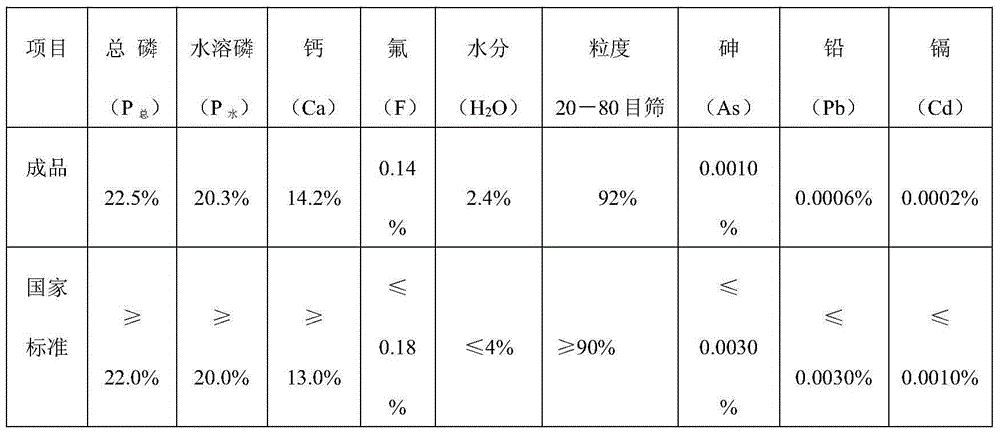

Embodiment 1

[0031] 1000Kg of wet-process phosphoric acid is reacted with 297.5Kg of calcium carbonate powder. Wet-process phosphoric acid is dilute phosphoric acid obtained from phosphate rock through sulfuric acid extraction reaction and filtration. Dilute phosphoric acid is then concentrated by indirect heating with steam. Concentrated phosphoric acid is defluorinated, dearsenic, and heavy metal removed. Obtained purified phosphoric acid. The reaction temperature is 65°C, and the reaction equipment can be a stirred vertical reactor, a horizontal reactor or a tubular reactor. Wet process phosphoric acid is calculated on the basis of phosphorus pentoxide 43wt%, the calcium carbonate content in the calcium carbonate powder is 98wt%, the water content is 0.1wt%, and the semi-finished product of calcium dihydrogen phosphate is 4636Kg, and the water content of the semi-finished product is about 18wt%. The standard feed-grade calcium dihydrogen phosphate product is 2503Kg and then dried after ...

Embodiment 2

[0037] React 100,000Kg of wet-process phosphoric acid with 33,213Kg of calcium carbonate powder at a reaction temperature of 65°C. The reaction equipment can be a vertical reactor with stirring, or a horizontal reactor or a tubular reactor. Wet-process phosphoric acid is calculated on the basis of phosphorus pentoxide 45wt%, calcium carbonate content in calcium carbonate powder is 98wt%, water content 0.1wt%, and 109658Kg of semi-finished calcium dihydrogen phosphate is produced, with a water content of 20wt%. The feed grade calcium dihydrogen phosphate product is 269374Kg and then dried after being returned. The drying equipment can be a rotary cylinder dryer or a flash steam dryer. The inlet hot air temperature is 300-600°C, and the outlet temperature of the rotary dryer is 80-110°C After drying, 89,791 kg of calcium dihydrogen phosphate is obtained, and the moisture content of the dried product is controlled between 1 and 4 wt%.

[0038] The particle size of the semi-finish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com