Garbage feeding control method and device and feeding trigger

A technology of a control device and a control method, which is applied in the direction of garbage transmission, garbage collection, storage devices, etc., can solve problems such as low efficiency and inaccurate control, and achieve the effects of avoiding material blockage, improving accuracy and control efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

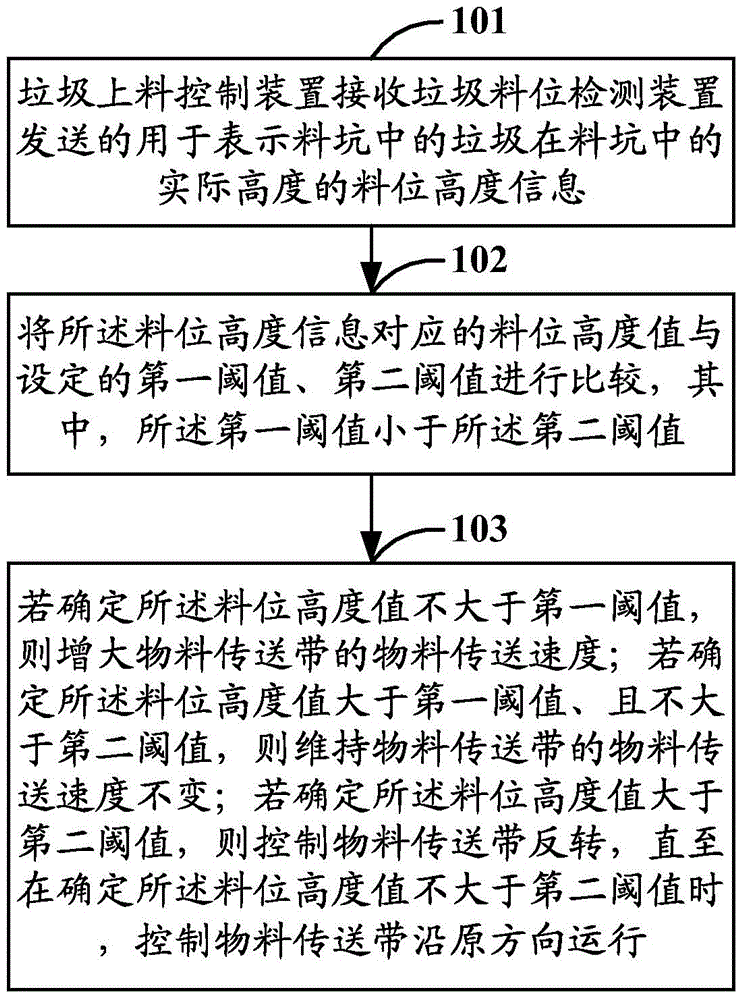

[0028] In order to realize the automatic feeding control of garbage, Embodiment 1 of the present invention provides a garbage feeding control method, such as figure 1 As shown, it is a schematic flow chart of the garbage feeding control method described in Embodiment 1 of the present invention, and the garbage feeding control method may include the following steps:

[0029] Step 101: The garbage feeding control device receives the material level height information sent by the garbage material level detection device, which is used to indicate the actual height of the garbage in the material pit in the material pit.

[0030] Optionally, the material level height information may specifically be sent by the garbage material level detection device to the garbage feeding control device through a data transmission line such as a CAN bus. The embodiment of the present invention does not repeat the information sent to the garbage feeding control device by means of wireless transmission...

Embodiment 2

[0091] Based on the same inventive concept as in Embodiment 1, Embodiment 2 of the present application provides a garbage feeding control device. For the specific implementation of the garbage feeding control device, please refer to the relevant description in Embodiment 1 of the above-mentioned method. Let me repeat. Specifically, as Figure 5 As shown, it is a schematic structural diagram of the garbage feeding control device described in Embodiment 2 of the present invention. The garbage feeding control device may mainly include:

[0092] The receiving unit 51 can be used to receive the material level height information sent by the garbage material level detection device for indicating the actual height of the garbage in the material pit in the material pit;

[0093] The processing unit 52 can be used to compare the material level height value corresponding to the material level height information with a set first threshold and a second threshold, wherein the first thresho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com