A preparation method of copper-based powder metallurgy parts with densified surface

A powder metallurgy and densification technology, applied in the field of preparation of copper-based powder metallurgy parts, can solve the problems of insufficient use of powder metallurgy process advantages, high manufacturing cost, long manufacturing process, etc., so as to reduce burrs and flashes. The effect of producing, reducing production cost and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The preparation method of the copper-based powder metallurgy parts with densified surface in this embodiment comprises the following steps:

[0034] (1) Design material composition: by weight percentage, the materials used include 0.15% carbon, 15% tin, no more than 2% unavoidable impurities and the balance of copper;

[0035] (2) Mixing: According to the material composition of step (1), each component is mixed to obtain a mixed powder, and a lubricant accounting for 0.5% of the total mass of the mixed material is added to the mixed powder;

[0036] (3) Compression: The mixture obtained in step (2) is pressed under a pressure of 400MPa to a density of 6.0g / cm 3 green parts, such as image 3 shown;

[0037] (4) Sintering: Sinter the green parts obtained in step (3) in a vacuum furnace, the sintering temperature is 700°C, and the sintering time is 180min;

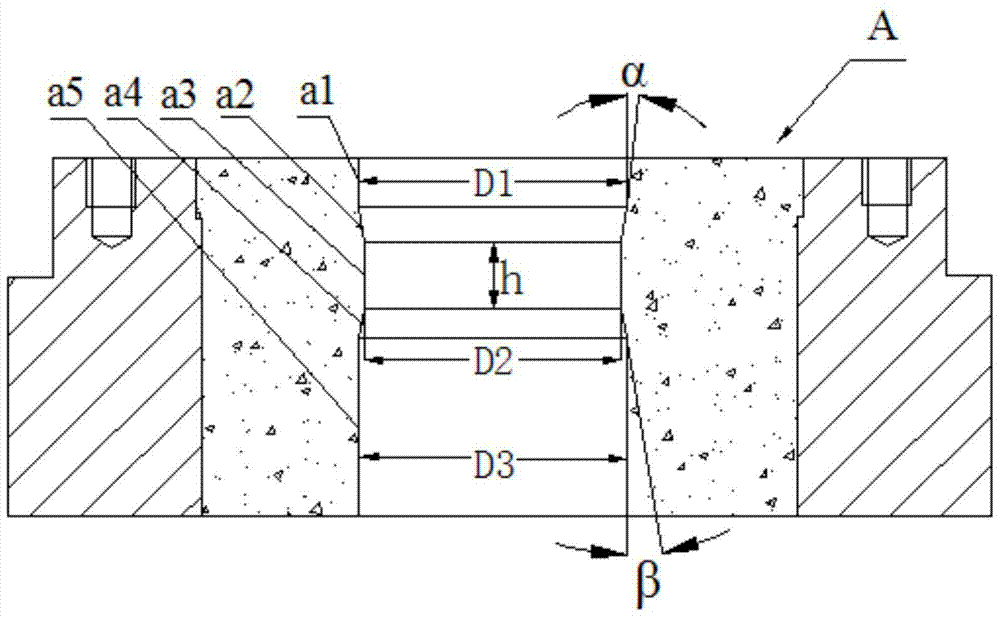

[0038] (5) extrusion: such as figure 1 As shown, the extrusion female die A used in this step has an extrusion c...

Embodiment 2

[0041] The preparation method of the copper-based powder metallurgy parts with densified surface in this embodiment comprises the following steps:

[0042] (1) Design material composition: by weight percentage, the materials used contain no more than 2% of unavoidable impurities and the balance of copper;

[0043] (2) Mixing: According to the material composition of step (1), each component is mixed to obtain a mixed powder, and a lubricant accounting for 0.1% of the total mass of the mixed material is added to the mixed powder;

[0044] (3) Compression: The mixture obtained in step (2) is compressed into a density of 6.8g / cm under a pressure of 500MPa 3 green parts, such as image 3 shown;

[0045] (4) Sintering: Sinter the green part obtained in step (3) in a nitrogen-hydrogen atmosphere containing 20 vol% of hydrogen, the sintering temperature is 1090° C., and the sintering time is 5 minutes;

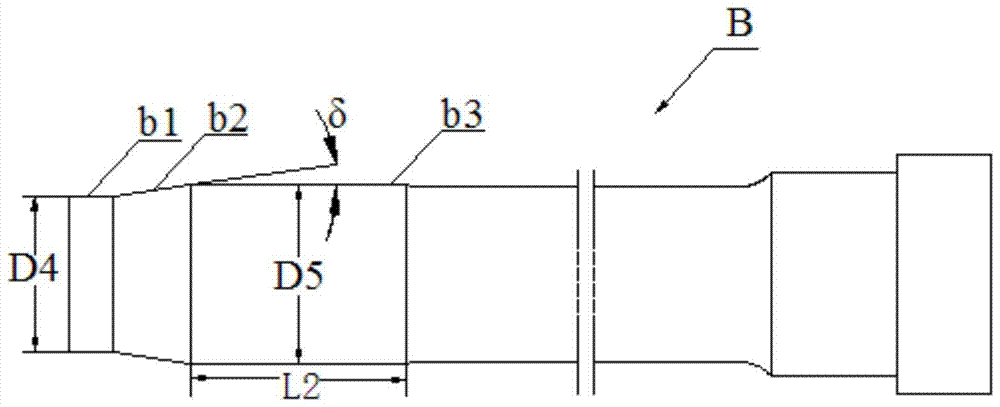

[0046] (5) extrusion: such as figure 2 As shown, the outer surface of the e...

Embodiment 3

[0049] The preparation method of the copper-based powder metallurgy parts with densified surface in this embodiment comprises the following steps:

[0050] (1) Design material composition: by weight percentage, the materials used include 0.8% carbon, 4% tin, 25% nickel, 5% zinc, 3% bismuth, no more than 2% of unavoidable impurities and the balance of copper;

[0051] (2) Mixing: According to the material composition of step (1), each component is mixed to obtain a mixed powder, and a lubricant accounting for 1% of the total mass of the mixed material is added to the mixed powder;

[0052] (3) Compression: The mixture obtained in step (2) is compressed into a density of 6.8g / cm under a pressure of 450MPa 3 green parts, such as image 3 shown;

[0053] (4) Sintering: sintering the green body of the part obtained in step (3) in a nitrogen-hydrogen atmosphere containing 10 vol% of hydrogen, the sintering temperature is 850° C., and the sintering time is 45 minutes;

[0054] (5)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com