Wide temperature range type phosphorus-containing cerium-based denitration catalyst and preparation method thereof

A denitrification catalyst, cerium-based technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

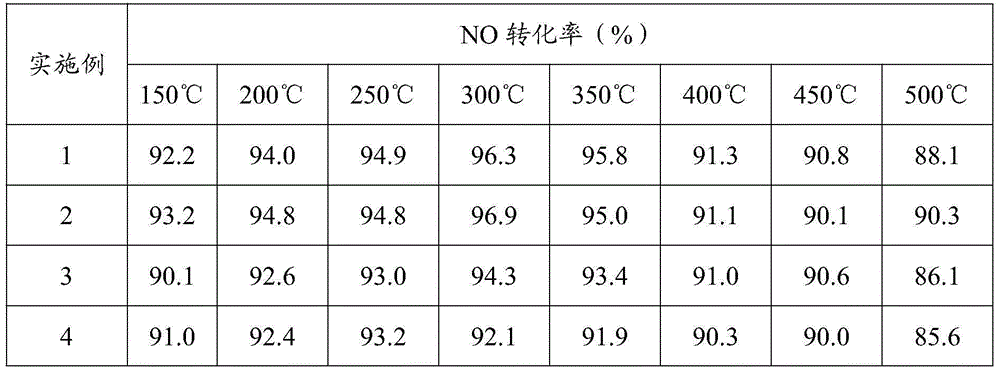

Examples

Embodiment 1

[0083] Example 1: Preparation of phosphorus-containing cerium-based denitration catalyst of the present invention

[0084] The implementation steps of this embodiment are as follows:

[0085] I, preparation solution A

[0086] Dissolve cerous nitrate in deionized water to obtain a cerous nitrate aqueous solution, and then add the cerous nitrate aqueous solution to the pyrophosphoric acid aqueous solution according to the molar ratio of cerous nitrate and pyrophosphoric acid as 1.0:1, and stir evenly Obtain solution A;

[0087] II. Prepare Solution B

[0088] According to the mol ratio of cerous nitrate and urea is 1.2:10, in the solution A that step 1 obtains, slowly add urea, allow urea to dissolve completely, obtain solution B;

[0089] III. Prepare Solution C

[0090] Dissolving manganese acetate in deionized water to obtain an aqueous solution of manganese acetate, and then slowly adding the aqueous solution of manganese acetate to solution B according to the molar rat...

Embodiment 2

[0096] Example 2: Preparation of phosphorus-containing cerium-based denitration catalyst of the present invention

[0097] The implementation steps of this embodiment are as follows:

[0098] I, preparation solution A

[0099] Dissolve cerous nitrate in deionized water to obtain a cerous nitrate aqueous solution, and then add the cerous nitrate aqueous solution to the pyrophosphoric acid aqueous solution according to the molar ratio of cerous nitrate and pyrophosphoric acid as 2.4:1, and stir evenly Obtain solution A;

[0100] II. Prepare Solution B

[0101] Be 2.2:10 according to the mol ratio of cerous nitrate and urea, slowly add urea in the solution A that step 1 obtains, allow urea to dissolve completely, obtain solution B;

[0102] III. Prepare Solution C

[0103] Dissolving manganese acetate in deionized water to obtain an aqueous solution of manganese acetate, and then slowly adding the aqueous solution of manganese acetate to solution B according to the molar rati...

Embodiment 3

[0109] Example 3: Preparation of phosphorus-containing cerium-based denitration catalyst of the present invention

[0110] The implementation steps of this embodiment are as follows:

[0111] I, preparation solution A

[0112] Dissolve cerous nitrate in deionized water to obtain a cerous nitrate aqueous solution, and then add the cerous nitrate aqueous solution to the pyrophosphoric acid aqueous solution according to the molar ratio of cerous nitrate and pyrophosphoric acid as 3.6:1, and stir evenly Obtain solution A;

[0113] II. Prepare Solution B

[0114] According to the mol ratio of cerous nitrate and urea is 0.5:10, slowly add urea in the solution A that step 1 obtains, allow urea to dissolve completely, obtain solution B;

[0115] III. Prepare Solution C

[0116] Dissolving manganese acetate in deionized water to obtain an aqueous solution of manganese acetate, and then slowly adding the aqueous solution of manganese acetate to solution B according to the molar rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com