Treatment equipment for high-density breeding circulating water

A technology for processing equipment and circulating water, which is applied in fish farming, application, animal husbandry, etc., and can solve the problems of easy breeding of bacteria and algae, occupancy, and large breeding sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

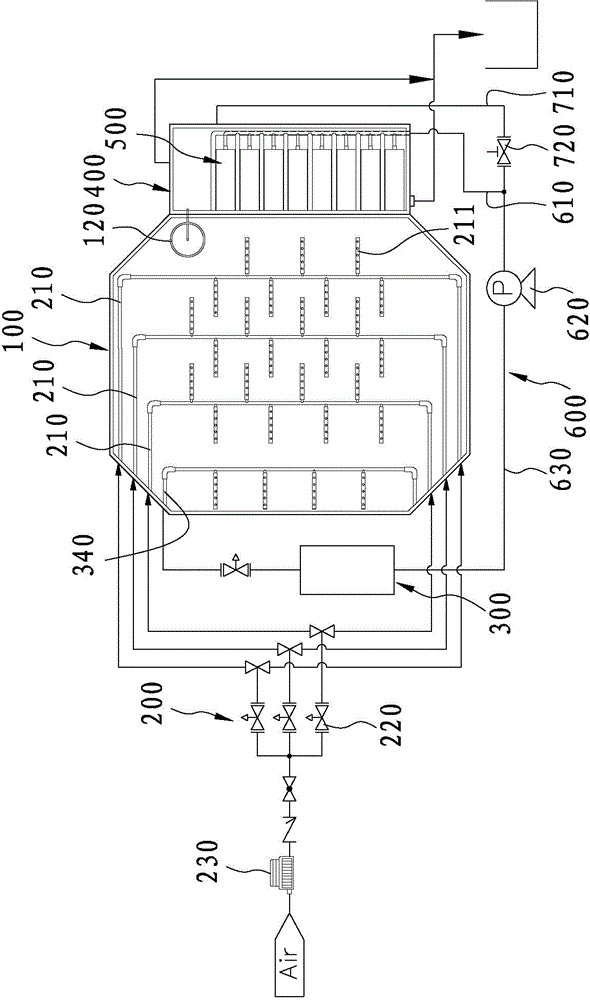

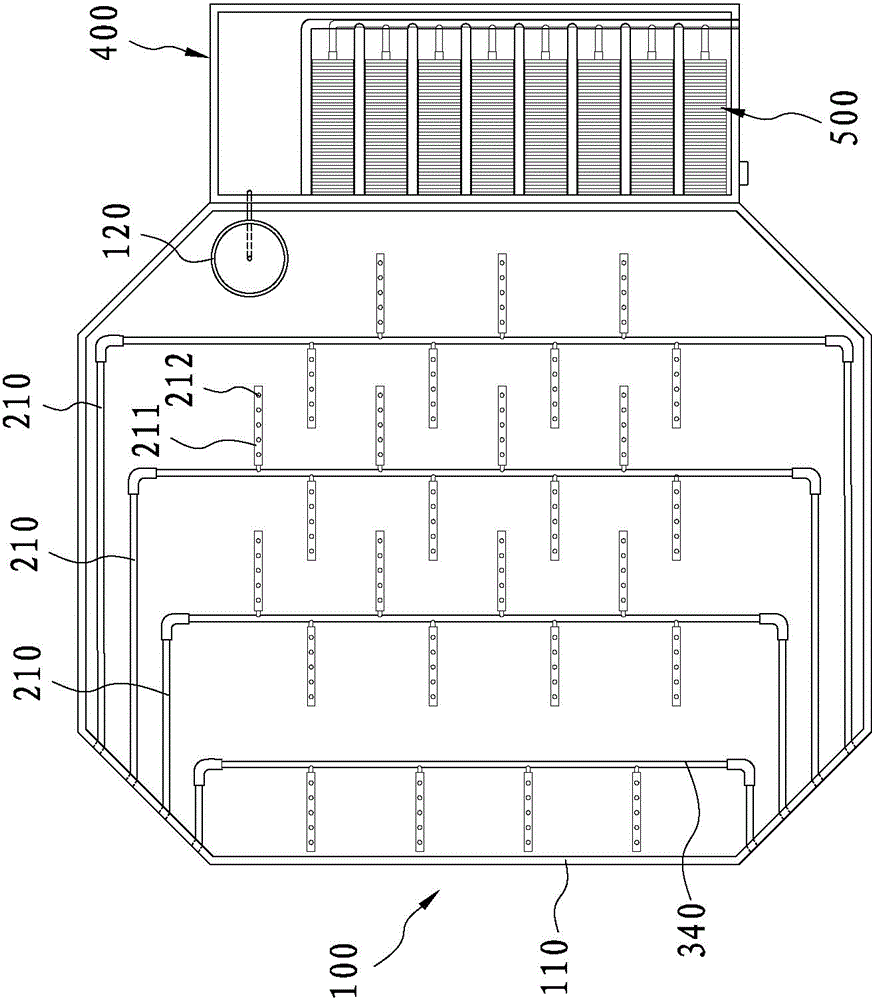

[0057] refer to figure 1 and Figure 5 , the first embodiment of the treatment equipment of high-density aquaculture circulating water of the present invention includes at least one aquaculture tank 100, an aeration unit 200, a sterilization unit 300, at least one circulating water treatment tank 400, and a plurality of membrane filtration units 500 , a return water unit 600 and a spray washing unit 700 .

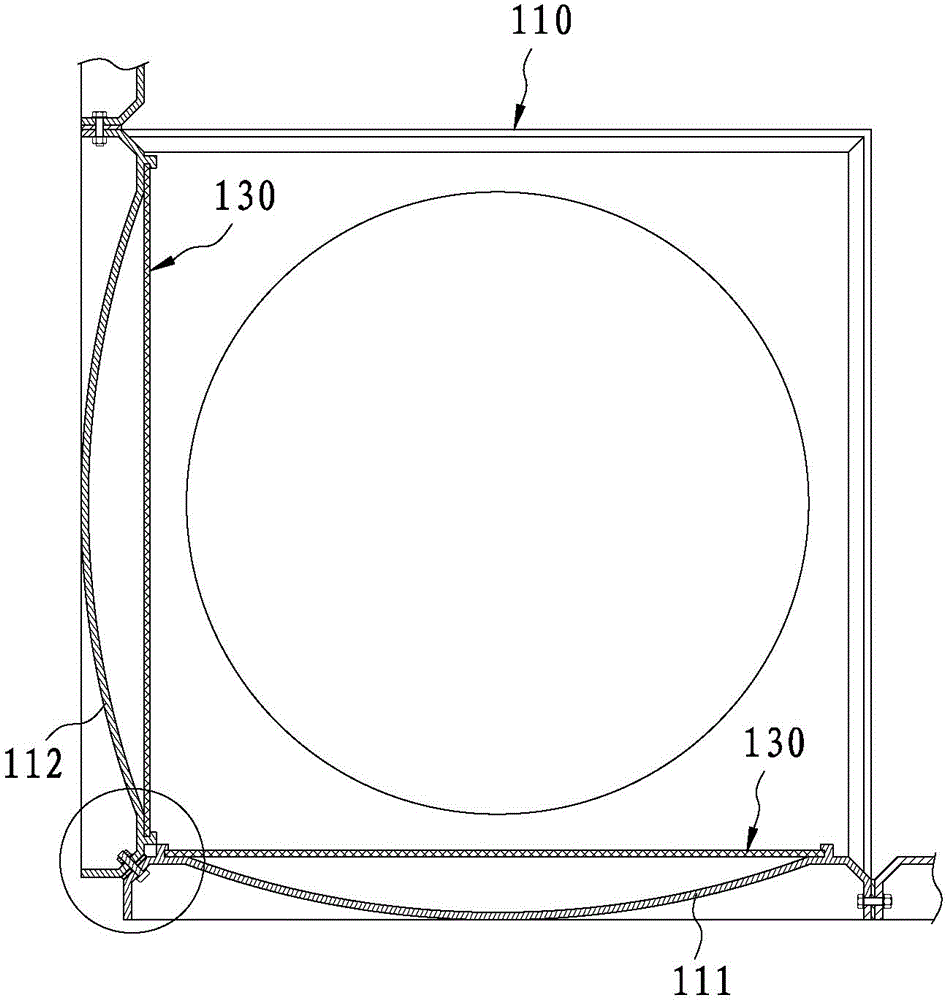

[0058] The breeding tank 100, please refer to Figure 2 to Figure 4 , is a detachable tank for containing pre-treated aquaculture water, and is an octagonal hollow tank formed by a plurality of substrate units 110 adjacent to each other, so that there is no dead angle on the water circulation, and for To reduce mold opening and manufacturing costs, the aforementioned substrate unit 110 can be expanded and extended by splicing boards 111 and 112 in equal proportions, and a watertight bead 113 is sandwiched between the joints of the boards 111 and 112 to prevent water in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com