High temperature resistant insulating adhesive tape substrate material

A technology of insulating tape and high temperature resistance, which is applied in the direction of adhesives, film/sheet adhesives, etc., and can solve the problem of lack of insulating tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0052] Examples and comparative examples provided below are provided to facilitate the understanding of the present invention, and these examples and comparative examples should not be construed as limiting the scope of the present invention. All parts and percentages are by weight unless otherwise indicated. The following illustrative examples and comparative examples were evaluated using the test methods and protocols described below.

[0053] material list

[0054]

[0055]

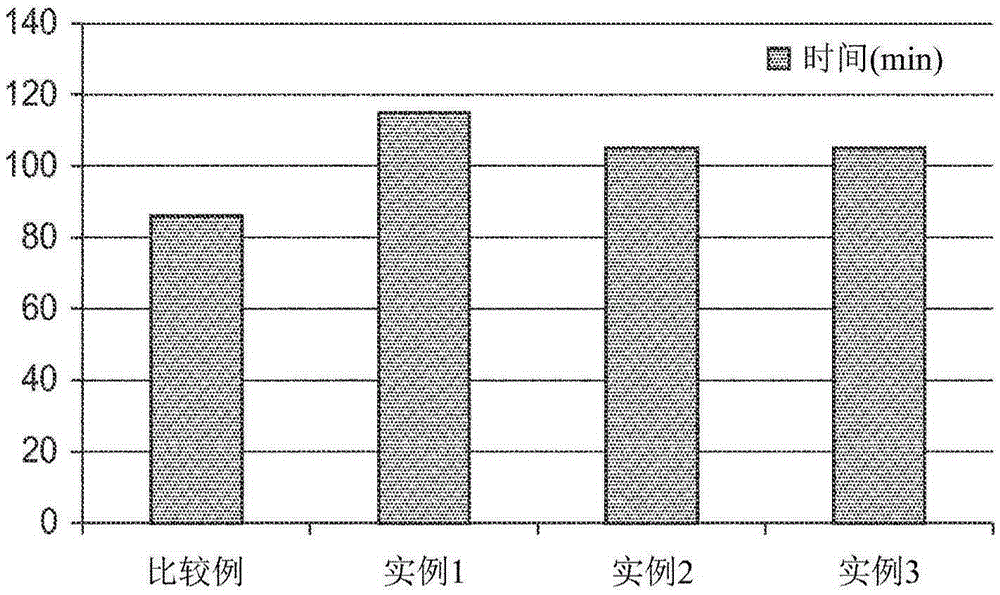

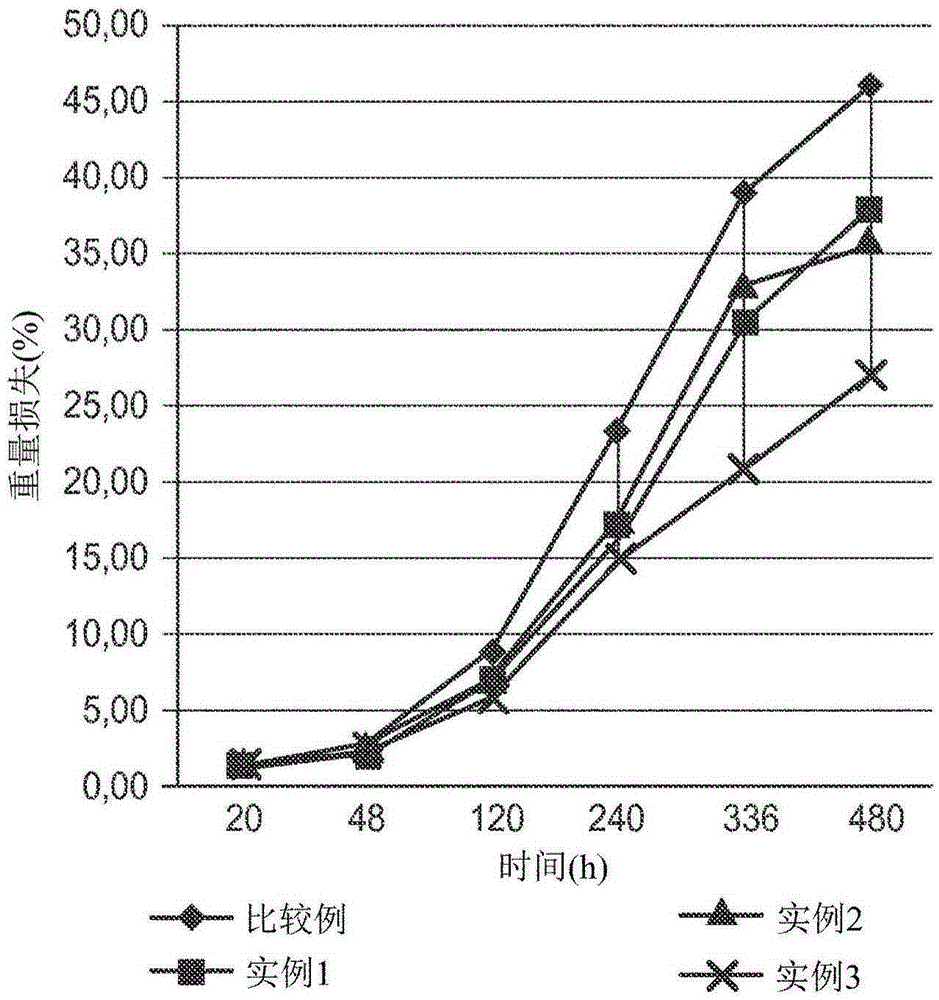

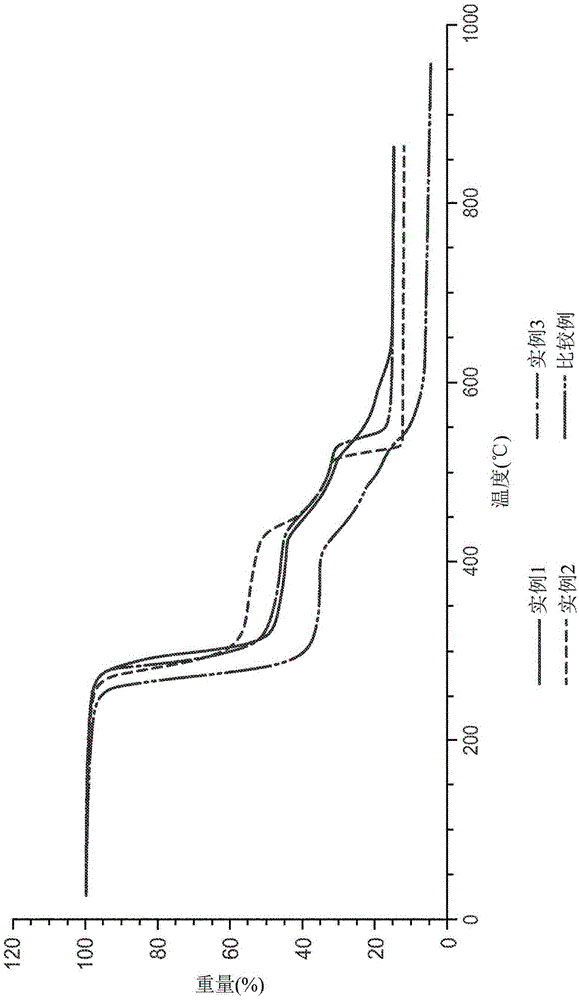

[0056] Four samples were prepared: Examples 1, 2 and 3 and Comparative Example 1. In addition, two formulations were prepared in which the CaCO3 filler was replaced by magnesia (composed of at least 88% MgO, supplied by Buschle & Lepper S.A.), such as 2, and aluminum silicate (composed of Al 2 o 3 , 2SiO 2 Composition, commercially available under the designation SAC100ZA, supplied by Imerys), eg 3. The compositions of the samples are shown in Table 3 and a description of the preparation o...

preparation example 1、2 and 3

[0060] 1. PVC resin, calcium / zinc (Ca / Zn) stabilizer, monomer plasticizer, polymer plasticizer, co-stabilizer, calcium carbonate (CaCO 3 ) or magnesium oxide or aluminum silicate, and antimony trioxide are added to the mixing device and treated at a temperature between 85°C and 105°C;

[0061] 2. Add the following components to the premix obtained in the previous step: nitrile rubber, antioxidant and black pigment and melt the material at a temperature comprised between 175°C and 195°C;

[0062] 3. Pour the mixture into homogenization equipment operating at a temperature between 170°C and 190°C;

[0063] 4. conveying the mixture to an extrusion device operating at a temperature between 170°C and 190°C, wherein said extrusion device feeds at least one calender;

[0064] 5. Processing the material in a calender until the desired thickness of the substrate is achieved, with a preferred thickness of 0.1 to 0.2 mm;

[0065] Subsequently, a water-based primer (synthetic and natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com