Cigarette paper quality stability testing method

A quality stability and test method technology, applied in the field of cigarette paper analysis, can solve the problems of overlapping chromatographic peaks, inability to separate, and interference of stability analysis of pyrolysis product integration results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the following examples:

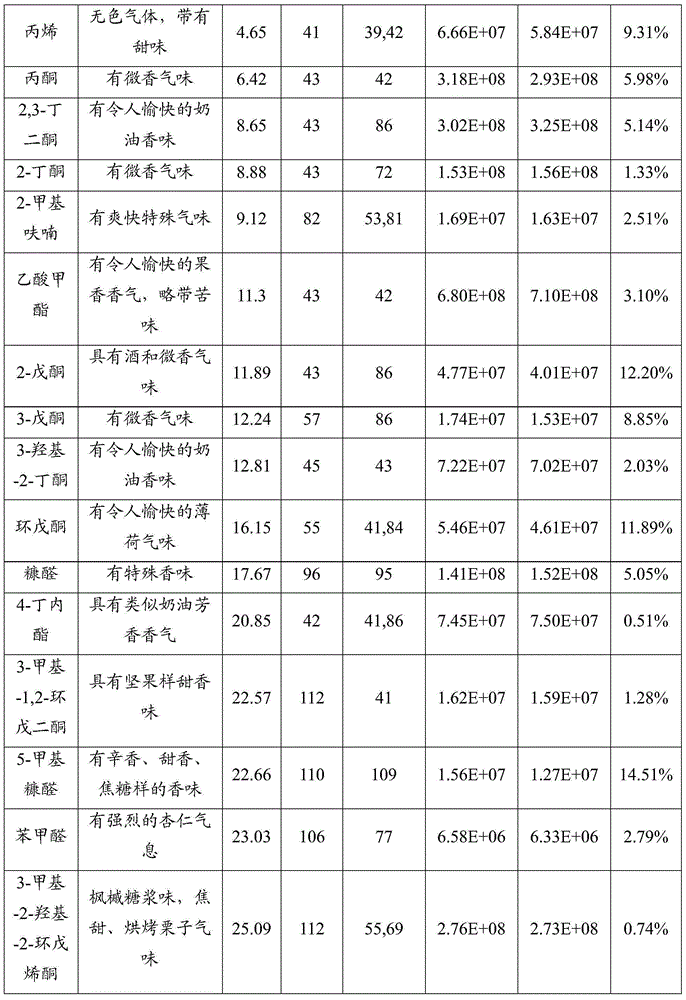

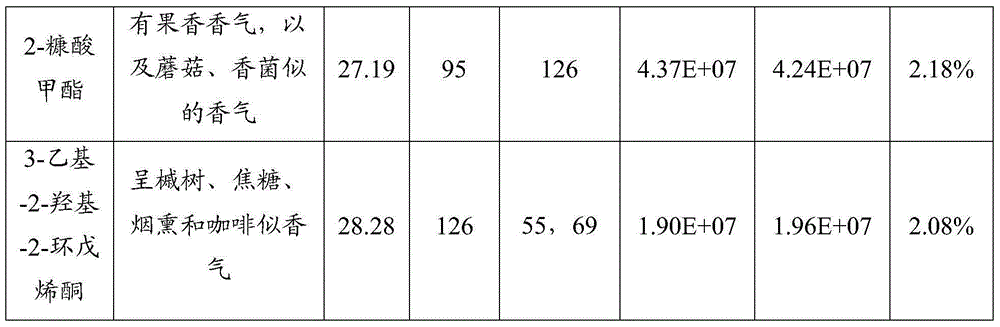

[0026] Take two different batches of cigarette paper in Specification A from the cigarette paper inventory, and one reel each. For each batch, after peeling off the outer layer of damaged paper, cut out no less than 20 layers along the full width, randomly Take 3 layers as lysed samples. Two different batches are batch A1 and batch A2, and each layer of each batch is used as a lysed sample, that is, batch A1 corresponds to lysed sample A1-1, lysed sample A1-2, and lysed sample A1-3 , Batch A2 corresponds to lysed sample A2-1, lysed sample A2-2, and lysed sample A2-3.

[0027] For each lysed sample, proceed as follows:

[0028] (1) Cut the lysed sample into 1mm 2 For the left and right pieces of paper, weigh 2.00 (±0.03) mg of cigarette paper fragments, place them in a quartz tube, and put them in a pyrolyzer for pyrolysis. The pyrolysis conditions are as follows:

[0029] G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com