Control method for preventing oil throwing during starting of multi-connected air conditioning unit

A control method and unit start-up technology, applied to compressors, refrigerators, refrigeration components, etc., can solve problems such as poor heating effect, large amount of oil thrown, hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

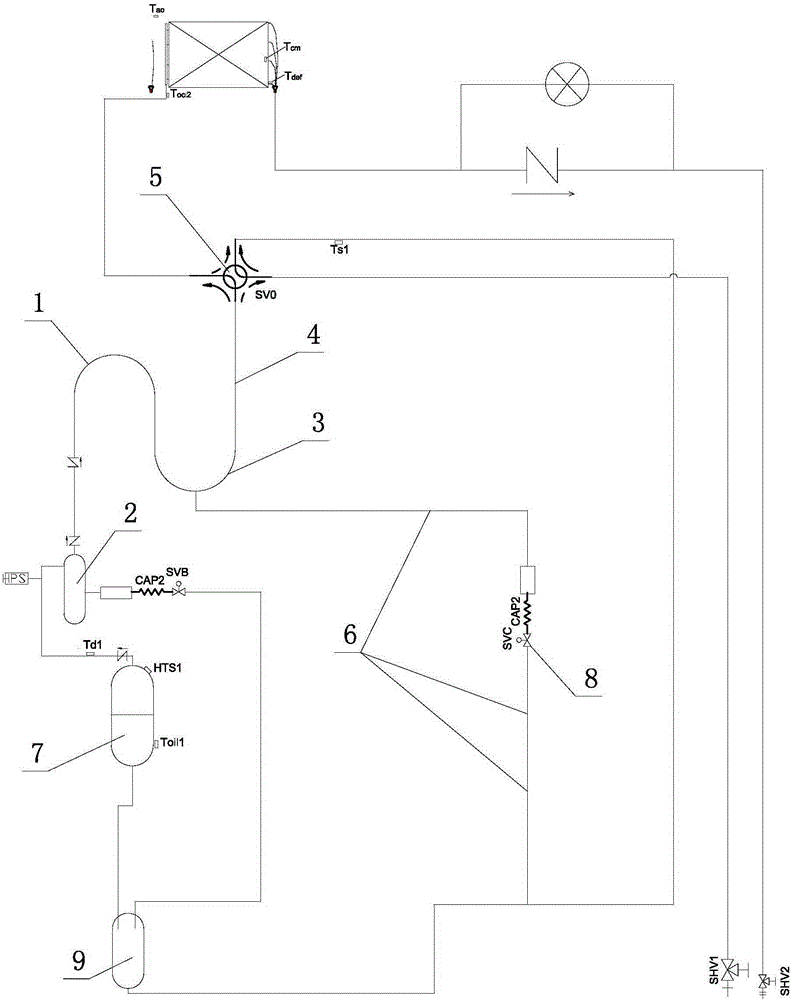

[0020] Such as figure 1 As shown, the present invention avoids the control method of oil throwing when the multi-unit unit starts, and its specific steps are as follows.

[0021] a. Connect the front end of an upper U-shaped pipe 1 to the outlet of the oil separator 2, connect the rear end of the upper U-shaped pipe 1 to the front end of the lower U-shaped pipe 3, and connect the rear end of the lower U-shaped pipe 3 to a The lower end of the extension vertical pipe 4 is connected, and the upper end of the extension vertical pipe 4 is connected with the first valve port of the four-way reversing valve 5 .

[0022] Connect the bottom of the lower U-shaped pipe 3 with the inlet of the compressor 7 (more specifically, the inlet of the gas-liquid separator 9) with an oil return line 6 with a solenoid valve 8 and a capillary tube. The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com