A new type of marine engineering pile foundation that reduces the displacement of the pile body and its manufacturing method

A marine engineering and displacement technology, which is applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve the problems of abnormal operation of superstructure, damage of pile body strength, deformation of pile foundation, etc. The effect of increasing the cross-sectional area of the body and the axial bearing capacity of multiple pile foundations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

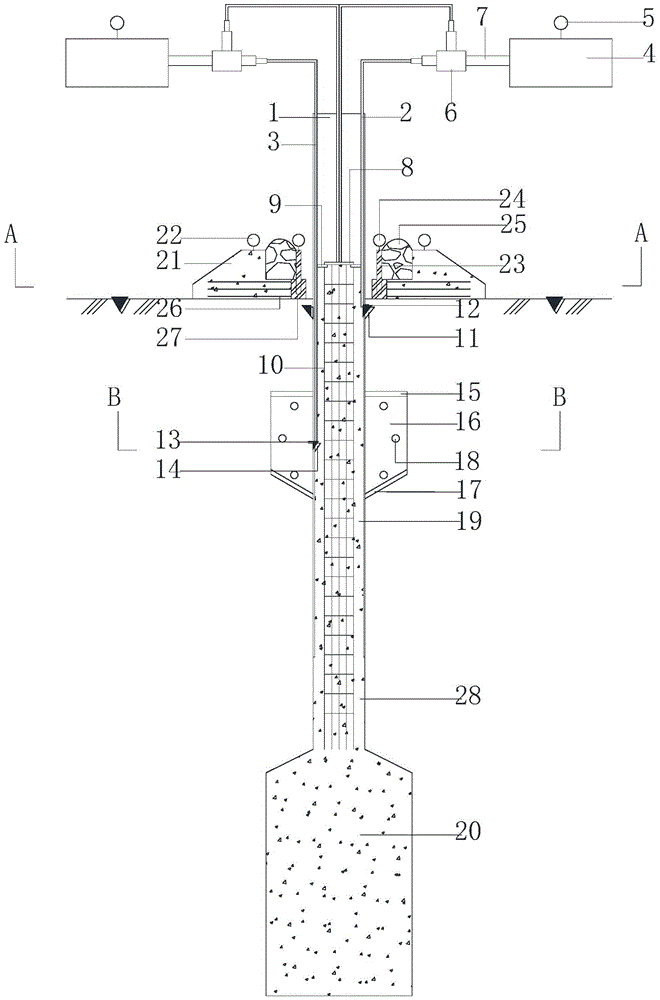

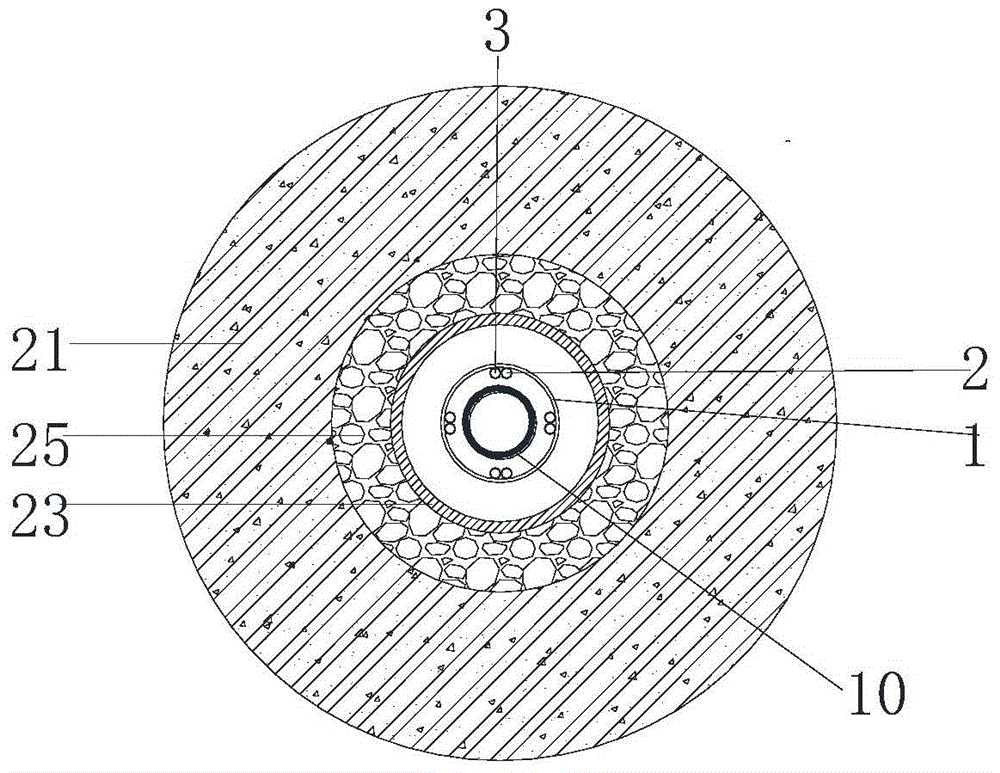

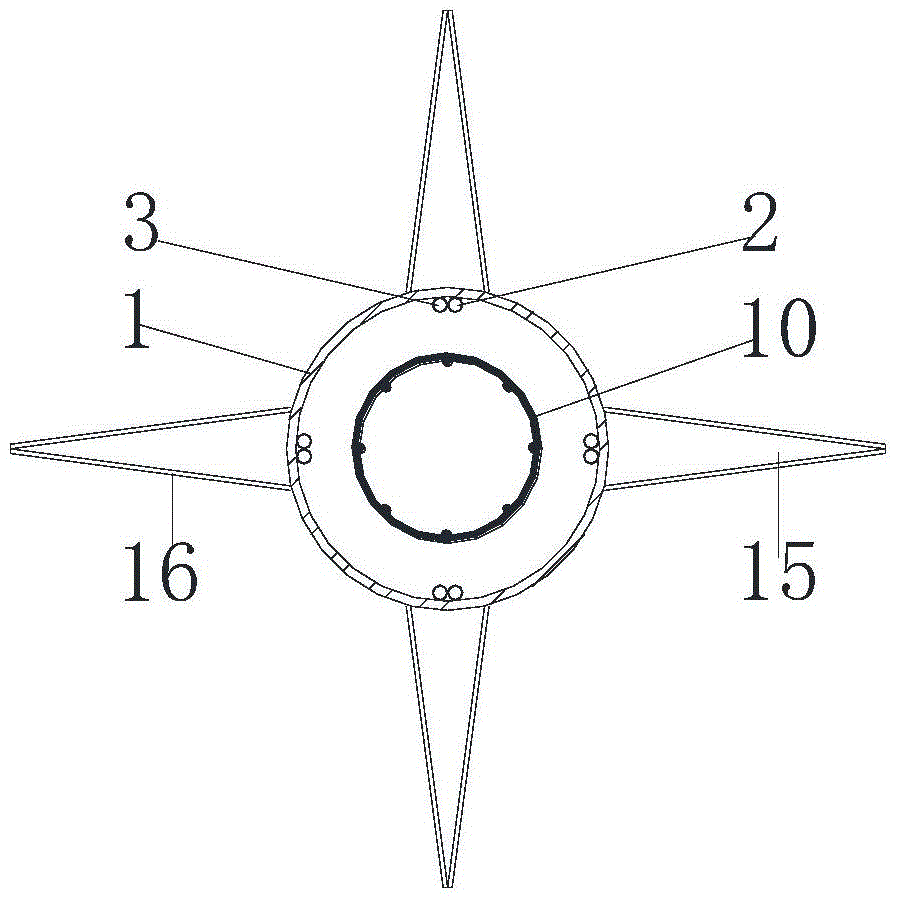

[0036] Such as Figure 1-Figure 4 As shown, a new type of marine engineering pile foundation that reduces the displacement of the pile body includes the upper steel pipe pile 1, the middle reinforced concrete pile 28 and the lower diameter expanded concrete pile 20 connected sequentially from top to bottom. 1 The inner concrete 19 of the steel pipe pile is poured in the lower part so as to form the lower enlarged concrete pile 20 and the middle reinforced concrete pile 28 in sequence. The pile diameter of the upper steel pipe pile 1 is equal to the pile diameter of the middle reinforced concrete pile 28, and the pile diameters of the two All less than the pile diameter of the bottom expanded diameter concrete pile 20. Therefore, the upper body of the pile foundation is a steel pipe pile, the lower body of the pile is concrete, and the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com