RH vacuum refining method for raising yield of antimony element

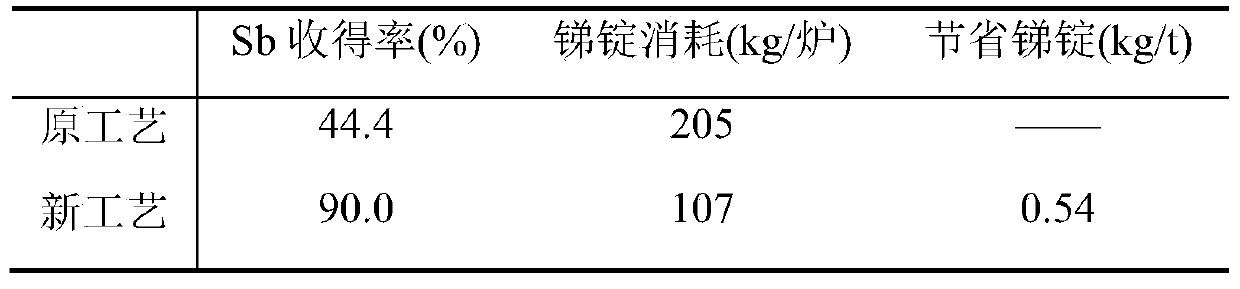

A technology of vacuum refining and yield, applied in the field of refining outside the molten steel furnace, can solve the problems of cost reduction and efficiency increase, long cycle time, waste of Sb elements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The steps in turn of the RH vacuum refining process technological method of the present invention are:

[0029] (1) Raise the ladle to the hydraulic lifting position, use the hydraulic device to lift the ladle, so that the dipping tube is immersed in the molten steel, and vacuum the vacuum chamber of the RH vacuum cycle refining device to reduce the vacuum to below the working vacuum. The molten steel is sucked into the vacuum chamber of the RH vacuum cycle refining, and the argon sending device blows the argon gas into the dipping tube through the lifting gas nozzle to realize the circulating flow of the molten steel in the RH refining device;

[0030] (2) Carry out decarburization treatment in a vacuum state, the decarburization time is 15-20min, and ensure the vacuum degree required for decarburization;

[0031] (3) Add an appropriate amount of slag surface deoxidizer to the slag surface of the ladle after the decarburization of molten steel is completed, and carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com