Fermented morinda citrifolia yellow rice wine and production method thereof

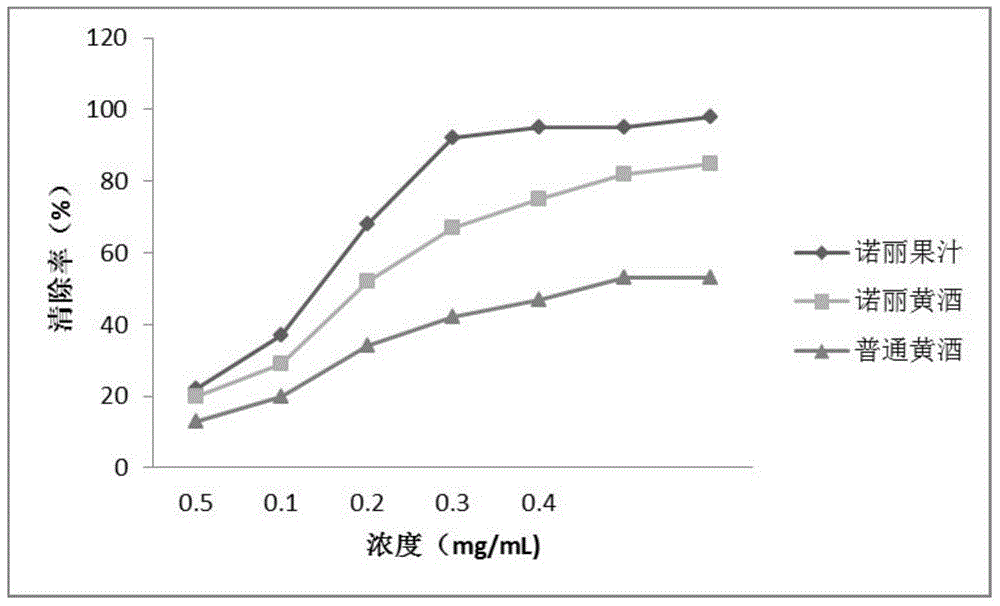

A production method and fermentation-type technology, applied in the field of bioengineering, can solve problems such as poor taste, and achieve the effects of enriching nutrition, improving immunity, and improving the strong taste of koji.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Raw material selection and cleaning: select high-quality, fresh and fully ripe noni fruit, wash the floating dust on the noni fruit peel with tap water and drain the water;

[0028] (2) Beating and juicing: Use a beater to beat the drained Noni fruit, first pass through a 150-mesh screen, then filter the peel through a scraper filter, let the filtrate stand for precipitation, and take the upper clarified Noni pulp;

[0029] (3) Pectinase treatment: add 12% pectinase to treat Noni pulp, the treatment conditions are: the dosage of pectinase is 0.03g / kg, the temperature is 40°C, and the pH is 2.0.

[0030] (4) Filtration: the Noni juice treated with pectinase is filtered through a cellulose acetate membrane to obtain clarified Noni juice.

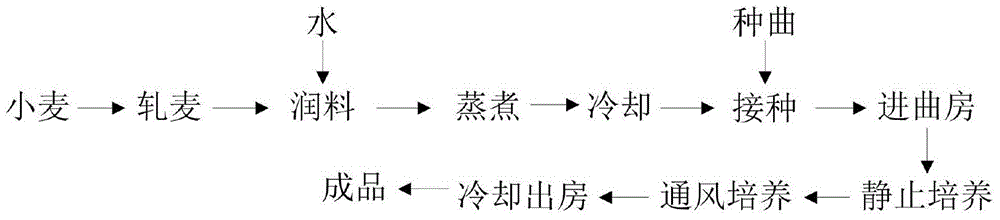

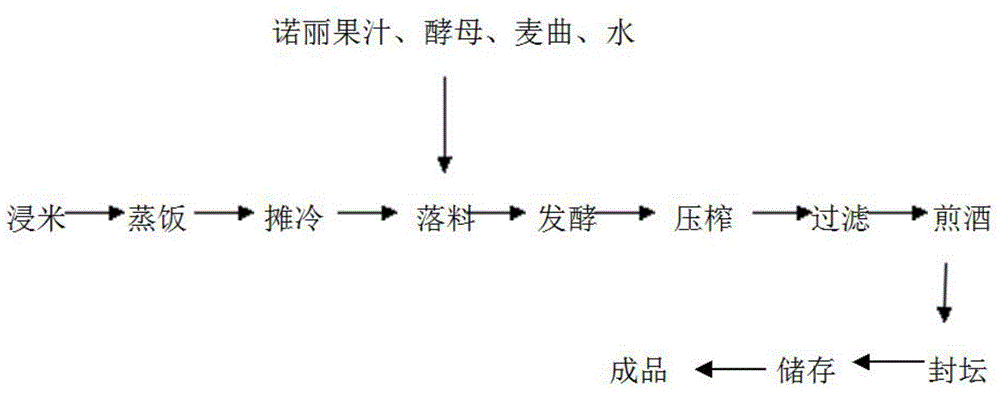

[0031] (5) Brewing: use figure 1 The technological process of brewing Noni rice wine:

[0032] The proportion of the formula when blanking is: glutinous rice: 80%, noni juice: 15%, natural koji: 10%, purebred koji: 3%, water: 100...

Embodiment 2

[0040] (1) Raw material selection and cleaning: select high-quality, fresh and fully ripe noni fruit, wash the floating dust on the noni fruit peel with tap water and drain the water;

[0041] (2) Beating and juicing: Use a beater to beat the drained Noni fruit, first pass through a 150-mesh screen, and then filter the peel through a scraper filter, let the filtrate stand for precipitation, and take the upper clarified Noni pulp;

[0042] (3) Pectinase treatment: add 13% pectinase to treat Noni pulp, the treatment conditions are: the amount of pectinase is 0.05g / kg, the temperature is 45°C, and the pH is 2.5;

[0043] (4) Filtration: the Noni juice processed through pectinase is carried out through cellulose acetate membrane filtration to obtain clarified Noni juice;

[0044] (5) Brewing: use figure 1 Process for brewing Noni rice wine:

[0045] The proportion of the formula when blanking is: glutinous rice: 85%, noni juice: 18%, natural koji: 13%, purebred koji: 4%, water:...

Embodiment 3

[0051] (1) Raw material selection and cleaning: select high-quality, fresh and fully ripe noni fruit, wash the floating dust on the noni fruit peel with tap water and drain the water;

[0052] (2) Beating and juicing: Use a beater to beat the drained Noni fruit, first pass through a sieve, and then filter the peel through a scraper filter, let the filtrate stand for precipitation, and take the upper clarified Noni fruit fruit pulp;

[0053] (3) Pectinase treatment: add 20% pectinase to treat Noni pulp, the treatment conditions are: the amount of pectinase is 0.06g / kg, the temperature is 50°C, and the pH is 3;

[0054] (4) Filtration: the Noni juice processed through pectinase is carried out through cellulose acetate membrane filtration to obtain clarified Noni juice;

[0055] (5) Brewing: use figure 1 Process for brewing Noni rice wine:

[0056] The proportion of the formula when blanking is: glutinous rice: 85%, noni juice: 20%, natural koji: 15%, purebred koji: 5%, water:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com