Coal additive for reducing smoke dust discharging quantity

A technology of coal additives and emissions, applied in the field of coal additives, can solve the problems of low coal quality, large smoke and dust emissions, low coal utilization and combustion efficiency, etc., to reduce emissions, improve coal combustion efficiency, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

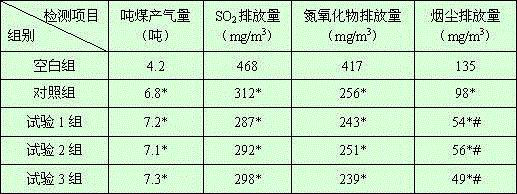

Examples

Embodiment 1

[0026] Party:

[0027] Nano silicon dioxide 10g, slag 10g, sodium percarbonate 4g, triethanolamine acetate 1g,

[0028] Manganese oxide 2g, magnesium oxide 2g, calcium hydroxide 2g, sodium dodecylbenzenesulfonate 0.2g,

[0029] Sodium chloride 1g, nitrate 1g, polyacrylamide 2g, high alumina bauxite 8g.

[0030] Preparation:

[0031] (1) Take sodium dodecylbenzenesulfonate and polyacrylamide, add deionized water, stir evenly, and obtain mixed solution A;

[0032] (2) Take nano silicon dioxide, slag, sodium percarbonate, triethanolamine acetate, manganese oxide, magnesium oxide, calcium hydroxide and high alumina bauxite, grind them into fine powder, add deionized water, stir evenly, and get Mixture B;

[0033] (3) Mix the above mixed solution A and mixed solution B, add sodium chloride and nitrate, and make a water dispersant according to the conventional method.

[0034] The concentration of the coal additive is 40%.

Embodiment 2

[0036] Party:

[0037] Nano silica 10g, slag 20g, sodium percarbonate 10g, triethanolamine acetate 5g,

[0038] Manganese oxide 8g, magnesium oxide 6g, calcium hydroxide 8g, sodium dodecylbenzenesulfonate 0.8g,

[0039] Sodium chloride 5g, nitrate 5g, polyacrylamide 6g, high alumina bauxite 16g.

[0040] Preparation:

[0041] (1) Take sodium dodecylbenzenesulfonate and polyacrylamide, add deionized water, stir evenly, and obtain mixed solution A;

[0042] (2) Take nano silicon dioxide, slag, sodium percarbonate, triethanolamine acetate, manganese oxide, magnesium oxide, calcium hydroxide and high alumina bauxite, grind them into fine powder, add deionized water, stir evenly, and get Mixture B;

[0043] (3) Mix the above mixed solution A and mixed solution B, add sodium chloride and nitrate, and make a water dispersant according to the conventional method.

[0044] The concentration of the coal additive is 60%.

Embodiment 3

[0046] Party:

[0047] Nano silicon dioxide 10g, slag 15g, sodium percarbonate 7g, triethanolamine acetate 3g,

[0048] Manganese oxide 5g, magnesium oxide 4g, calcium hydroxide 5g, sodium dodecylbenzenesulfonate 0.5g,

[0049] Sodium chloride 3g, nitrate 3g, polyacrylamide 4g, high alumina bauxite 12g.

[0050] Preparation:

[0051] (1) Take sodium dodecylbenzenesulfonate and polyacrylamide, add deionized water, stir evenly, and obtain mixed solution A;

[0052] (2) Take nano silicon dioxide, slag, sodium percarbonate, triethanolamine acetate, manganese oxide, magnesium oxide, calcium hydroxide and high alumina bauxite, grind them into fine powder, add deionized water, stir evenly, and get Mixture B;

[0053] (3) Mix the above mixed solution A and mixed solution B, add sodium chloride and nitrate, and make a water dispersant according to the conventional method.

[0054] The concentration of the coal additive is 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com