High-yield preparation method for high-purity low-molecular-weight lignin

A low molecular weight, lignin technology, applied in the field of biochemical industry, can solve the problems of serious environmental pollution, low yield and high molecular weight of lignin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

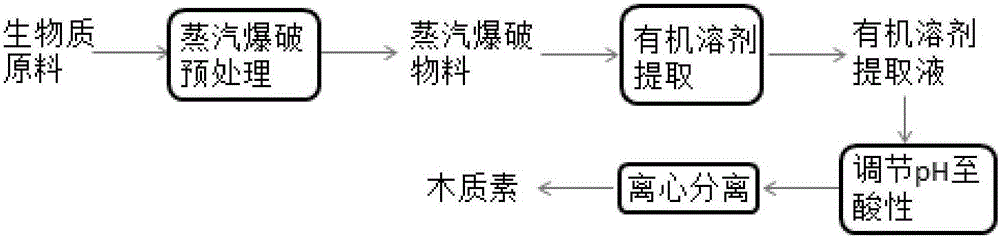

Method used

Image

Examples

Embodiment 1

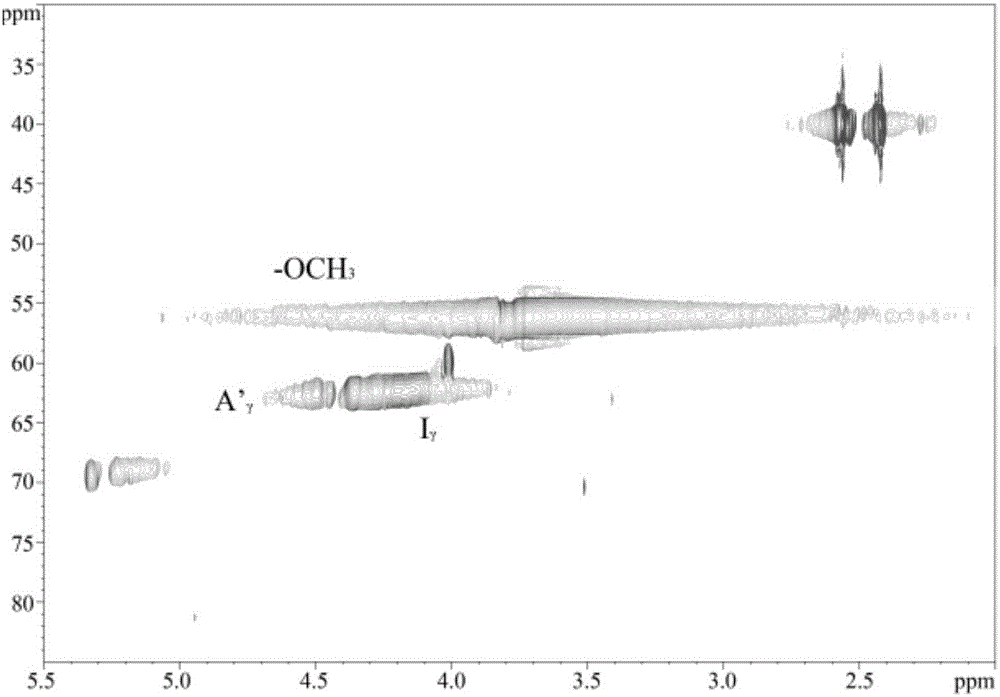

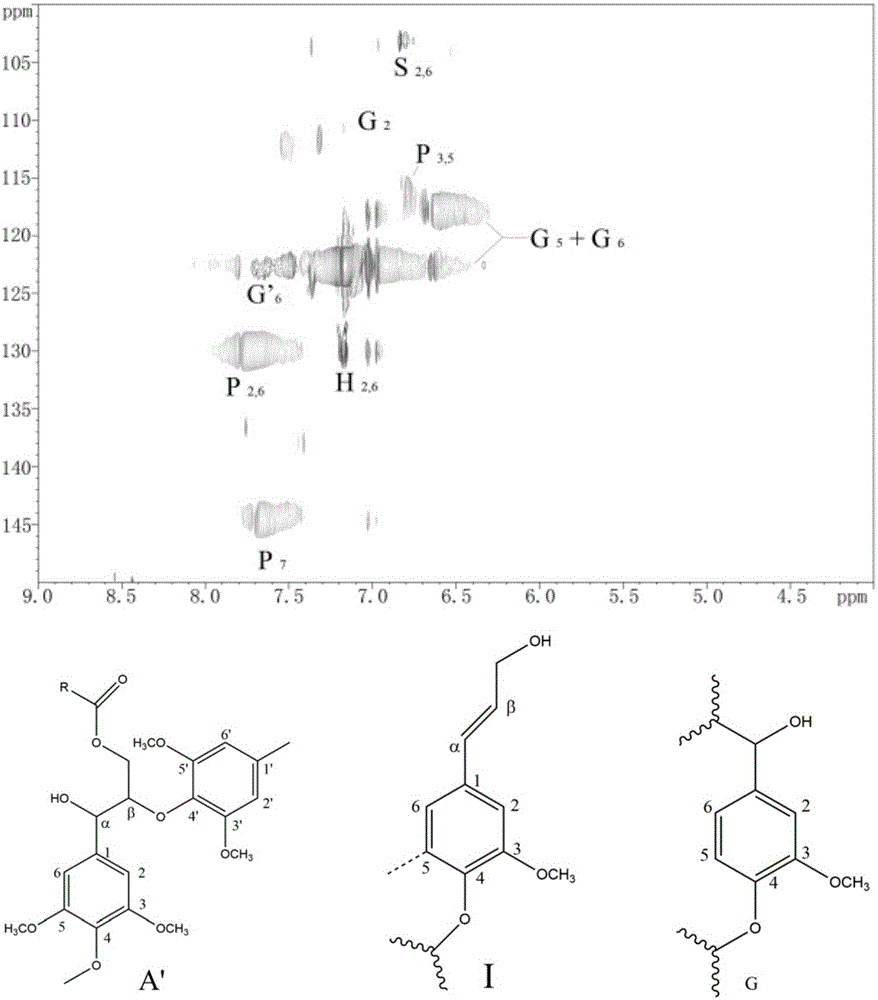

[0023] High-purity low-molecular-weight lignin is prepared with high yields from corn cobs. The specific method is: take 200 g of corn cobs that are crushed to a diameter of about 2 cm, soak them in 0.5% (w / w) dilute sulfuric acid solution and place them at room temperature for 8 hours, and filter them by suction. Separation of solid and liquid. Pour the pre-impregnated corncobs into the screw pressure continuous steam explosion extruder, feed the steam pressure to 1.5MPa, and the corncobs stay in the retainer for 5min, release the pressure to a standard atmospheric pressure to obtain steam explosion materials, wash with water drying. Get 5g of dry steam-explosion material and join 50ml, 80% (v / v) ethanol aqueous solution with solid-to-liquid ratio 1 / 10 (w / w), heat up to 160 ℃ in autoclave, set stirring speed 500rpm, React for 2 hours. After cooling to room temperature, the extract was separated by filtration, and an appropriate amount of 0.5% (w / w) dilute sulfuric acid solu...

Embodiment 2

[0025] Using cassava distiller's residue as raw material to prepare high-purity low-molecular-weight lignin with high yield, the specific method is: take 200g of cassava distiller's residue, wash the raw material with water to remove dust, impurities and sugar, immerse in 0.2% (w / w) hydrochloric acid solution and place it at room temperature for 10 hours , and the solid-liquid was separated by suction filtration. Pour the pre-soaked cassava distiller's residue into a screw-pressurized continuous steam explosion extruder. The steam pressure is 1.2MPa. The cassava distiller's residue stays in the retainer for 8 minutes, and the pressure is released to a standard atmospheric pressure to obtain the steam explosion material. , wash and tumble dry. Take 5g of dry steam explosion material and add it to 75ml, 96% (v / v) 1,4-dioxane aqueous solution at a solid-to-liquid ratio of 1 / 15 (w / w), and heat up to 200 in the autoclave °C, set the stirring speed at 500 rpm, and react for 2 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com