Stone cutting production line

A production line and stone strip technology, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems that ordinary stone cutting equipment cannot meet the production needs, the processing accuracy cannot be guaranteed, and the floor space is large. Achieve the effect of saving hoisting equipment and handling procedures, stable operation of equipment and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

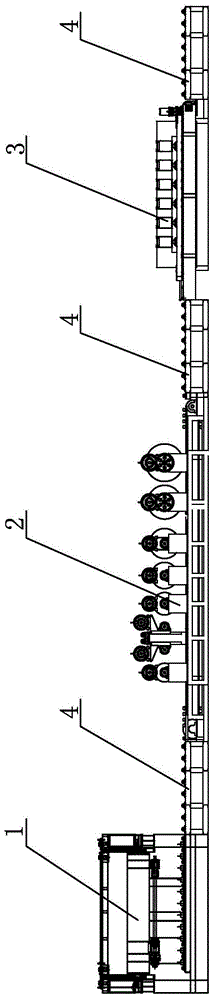

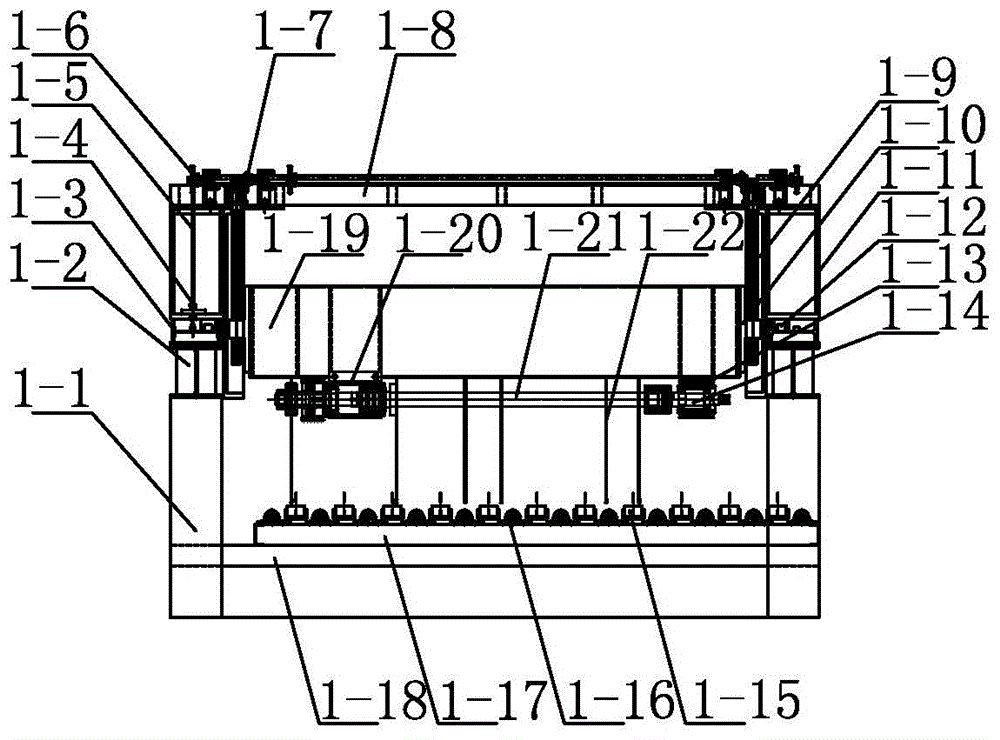

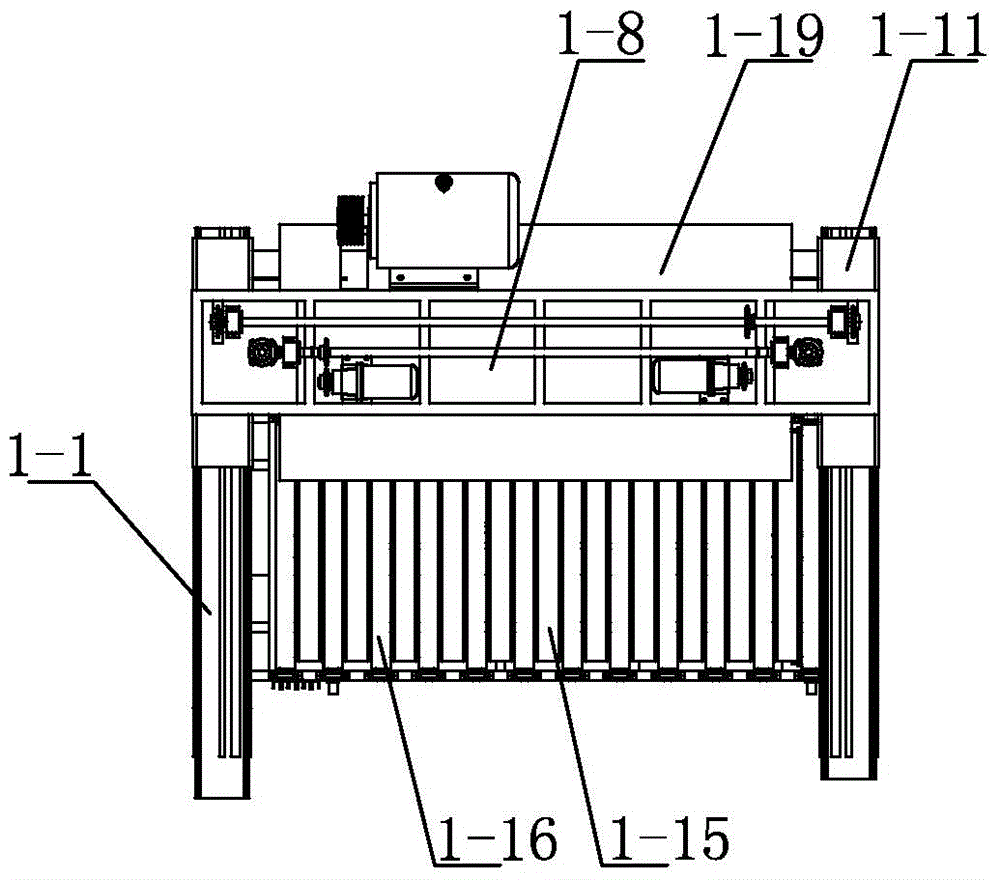

[0036] Such as Figure 1-Figure 16 As shown, the stone cutting production line includes a straight cutting machine 1, a stone cutting chamfering machine 2 and a mill 3 connected in sequence by a transition frame 4, and the straight cutting machine 1 includes a main frame 1-1, and a main frame 1- 1 is provided with a mine car, and the mine car is divided into an upper mine car 1-17 and a lower mine car 1-18, and a skid 1-15 is placed on the lower mine car 1-18, and a lifting device is provided on the lower mine car 1-18 , Drum 1-16 is housed on the mine car 1-17, and the two ends of main frame 1-1 are provided with horizontal traveling mechanism, and upper crossbeam 1-8 is arranged between two horizontal traveling mechanisms, and upper crossbeam 1-8 is provided with There is a vertical lifting mechanism, the vertical lifting mechanism is connected to the main be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com