Compression spring coiling method based on automatic spring coiling machine

A technology of compression spring and coil spring machine, which is applied in the field of compression spring and coil spring, can solve the problems of material waste and low trial production efficiency, and achieve the effects of saving sample test materials, high trial production efficiency, and reducing blindness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] A kind of spring processing method, its concrete steps comprise:

[0064] Below to Figure 4 Shown certain spring, take the Z53-14 type automatic coiling machine that Luoyang machine tool factory produces as example, illustrate the specific implementation steps of the inventive method, its method process is as follows Figure 5 shown.

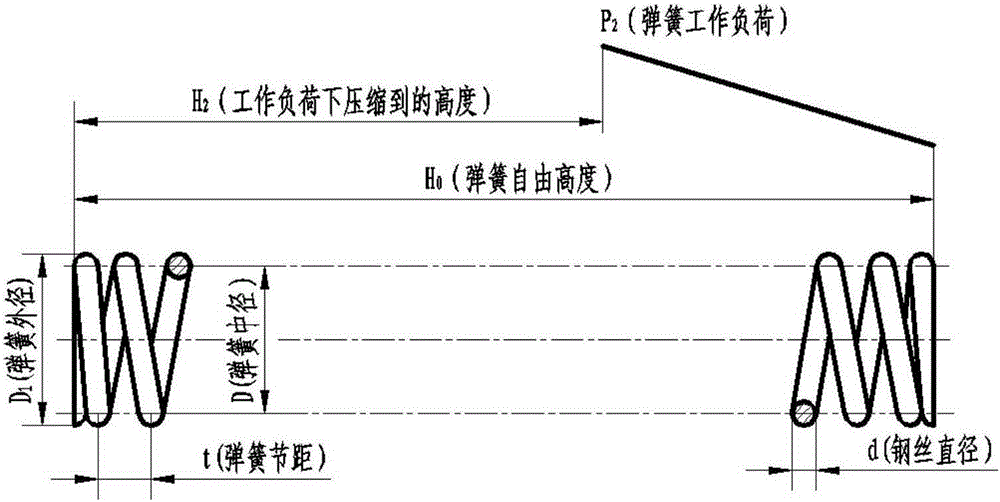

[0065] 1. Record the relevant parameter data of the target spring, the specific data is shown in Table 1:

[0066] Table 1 target spring parameter record table

[0067]

[0068] 2. Record the spring process test parameters according to the target spring parameters and material specifications, and the parameters are shown in Table 2;

[0069] Table 2 Spring process test parameter record table

[0070]

[0071] Determine the outer diameter and height of the spring rolling parameters according to the "initial size" in Table 2. When the initial size is determined, the size in the drawing should be appropriately enlarged or reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com